A Comprehensive Guide to Turbo Air Products

Why Turbo Air Technology Matters for Modern Refrigeration

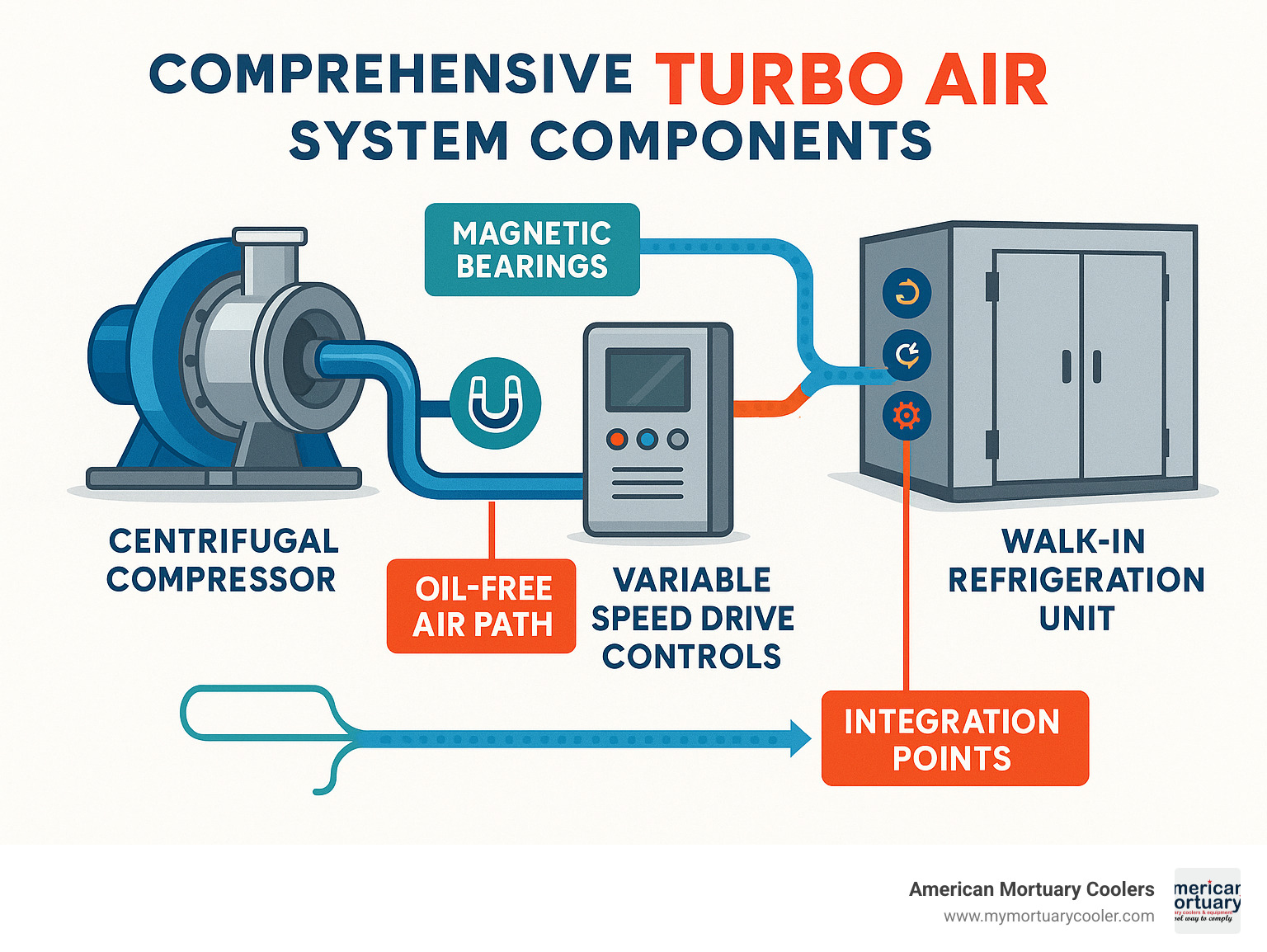

Turbo air refers to advanced compressed air systems that use high-speed centrifugal technology to deliver oil-free, energy-efficient air compression for industrial and commercial applications. These systems convert kinetic energy from rotating impellers into pressurized air through diffusers, eliminating the need for oil lubrication.

Key turbo air applications include:

- Walk-in coolers and freezers (energy-efficient refrigeration)

- Food processing facilities (contamination-free air)

- Pharmaceutical manufacturing (ISO 8573-1 certified purity)

- Industrial compressed air systems (oil-free operation)

- HVAC systems (natural refrigerant compatibility)

The technology has evolved significantly over 60 years, with modern turbo air compressors offering 100% oil-free operation, magnetic bearing systems, and smart controls like the MAESTRO™ interface. Companies like Turbo Air have developed 500+ refrigeration units with 140+ Energy Star certified models.

Unlike traditional screw or piston compressors, turbo air systems provide:

- Energy efficiency - Variable speed drives reduce power consumption

- Oil-free operation - Eliminates contamination risks

- Low maintenance - Touch-free magnetic bearings reduce wear

- Quiet operation - Typically 65 dB or lower noise levels

- Compact footprint - Higher power density than conventional compressors

However, these systems come with higher upfront costs and complexity. The initial investment is often offset by lower operating costs over the equipment's 20-year design life.

I'm Mortuary Cooler, a national-level mortuary cooler supplier specializing in American-made refrigeration solutions. With experience in commercial cold storage applications, I've seen how turbo air technology transforms facility operations through improved reliability and energy savings.

Quick turbo air definitions:

Understanding Turbo Air Technology & Components

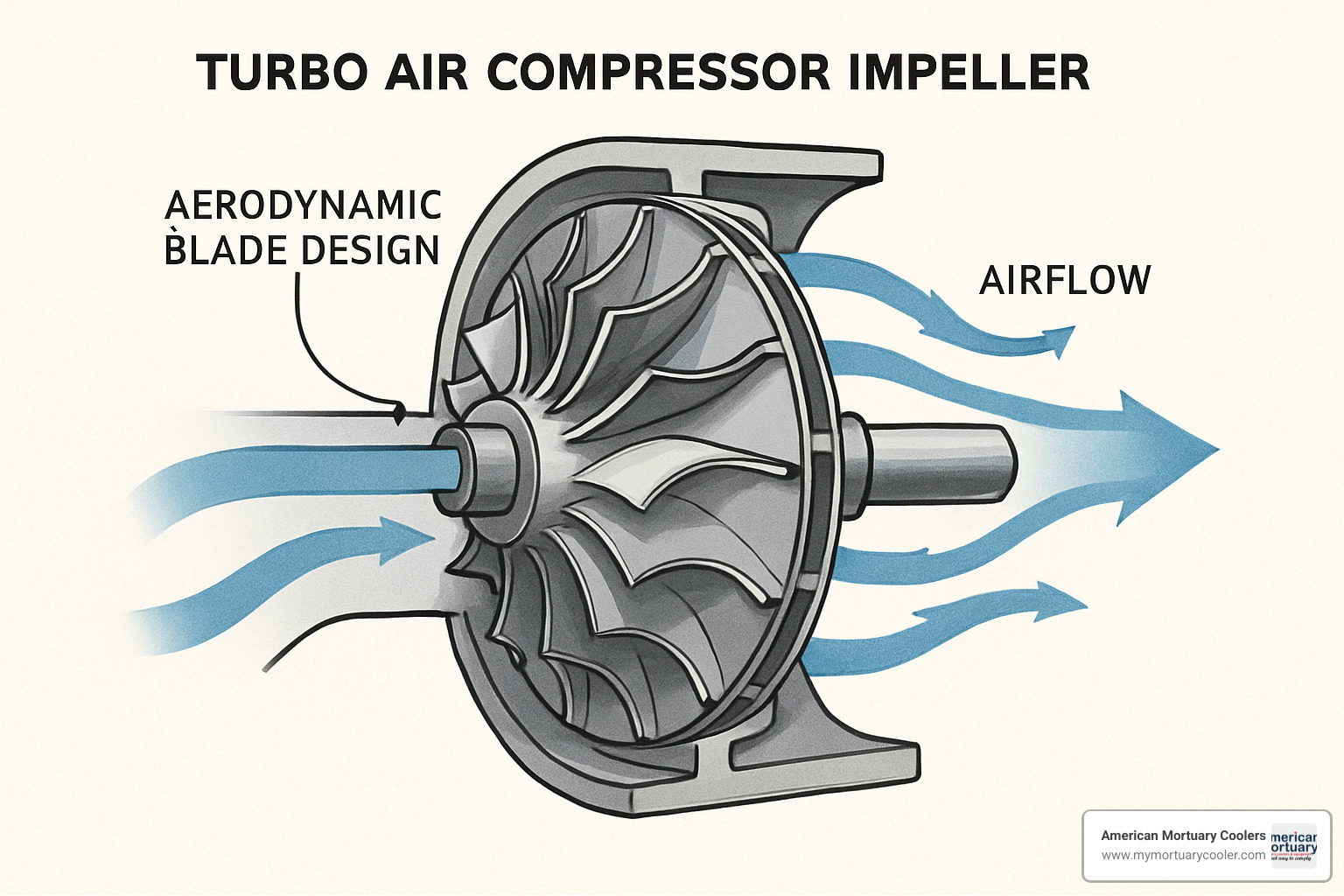

Turbo air technology uses the centrifugal principle - a spinning impeller grabs air and flings it outward at high speed, then channels that air through a diffuser that slows it down and builds pressure.

What makes this special? It's completely oil-free. While typical compressors need oil lubrication, turbo air systems float their spinning parts on cushions of air or magnetic fields. No oil means no contamination - crucial for food, medicine, or any application where clean air matters.

The real brain of modern turbo air systems is the control technology. MAESTRO™ controls act like smart assistants that monitor everything, prevent problems, and allow remote system monitoring.

Surge control is critical - when airflow gets disrupted, it can damage the compressor. Good surge control systems automatically adjust to keep everything running smoothly.

How turbo air compressors work

Turbo air compression happens in two steps: the impeller spins at 20,000+ RPM, grabbing air from the center and flinging it outward with kinetic energy. Then the diffuser gradually slows the air down, converting motion energy into pressure energy.

Unlike piston compressors that pulse, turbo air systems provide smooth, continuous airflow with no vibration - making them much quieter than traditional compressors.

Core components inside a turbo air system

The rotor uses precision five-axis milling for optimal aerodynamics. Gas-dynamic bearings use compressed air to create floating cushions, eliminating metal-on-metal contact and wear.

The intercooler cools air between compression stages for improved efficiency. Modern control panels include integrated monitoring, automated adjustments, and predictive maintenance alerts.

Cutting-edge innovations driving turbo air

Magnetic bearings use electromagnetic fields to levitate the rotor with no physical contact, resulting in virtually no maintenance and long service life.

Variable-speed drives adjust speed to match demand exactly, like cruise control for compressors. Natural refrigerants like propane (R290) offer nearly zero environmental impact.

The touch-free design eliminates physical contact points, dramatically reducing maintenance needs. Latest research on sustainable compressors shows this approach significantly extends equipment life while reducing operating costs.

Major Types of Turbo Air Compressors & Systems

Turbo air technology includes centrifugal compressors and axial compressors. Centrifugal designs are workhorses for commercial and industrial settings, handling moderate to high pressures with flow ranges from 1,200 to 480,000 Nm³/h and pressures up to 12.0 MPa.

Axial compressors excel at moving huge volumes of air at low pressures for big HVAC systems or industrial ventilation.

The shift to oil-free technology has become standard for industries like food processing, pharmaceuticals, and electronics manufacturing that can't risk oil contamination.

Turbo Air centrifugal units for industrial duty

Industrial centrifugal turbo air compressors use multi-stage design for continuous operation in tough environments. Unlike traditional compressors needing multiple machines for capacity, centrifugal systems scale smoothly for any flow requirement.

ISO 8573-1 Class 0 certification means oil content is so low it's unmeasurable - essential for pharmaceuticals and food processing where contamination could be disastrous.

Oil-free turbo air technology for sensitive applications

Pharmaceutical manufacturing requires consistent quality, reliability, and complete air purity documentation. Food and beverage industry uses oil-free turbo air to eliminate contamination risks that could cause recalls and regulatory violations.

Contamination-free operation includes additional filtration for moisture, particles, and microorganisms, ideal for cleanrooms and sterile manufacturing.

More info about walk-in compressor choices helps understand options for specific needs.

Integrating turbo air with walk-in coolers & freezers

Turbo air systems provide clean, reliable compressed air for controls, defrost systems, and pneumatic operations in walk-in coolers and freezers. The smooth air delivery improves heat transfer efficiency and reduces temperature fluctuations.

Energy Star certified models increasingly use turbo air technology to meet efficiency requirements while delivering superior reliability.

At American Mortuary Coolers in Tennessee, we've seen growing interest in turbo air integration for mortuary applications requiring precise temperature control and hygienic operation. Turbo Mexico Turbo Mexico showcases innovative applications in specialized cooling systems.

Advantages & Limitations of Turbo Air Solutions

Turbo air technology offers significant benefits but isn't perfect for every application. After working with countless refrigeration systems, I've seen how these compressors transform operations when properly matched.

Energy efficiency tops the advantages list. These units consistently outperform traditional compressors by maintaining peak efficiency across varying loads through variable-speed drives and precision-engineered impellers.

100% oil-free air eliminates contamination worries, oil disposal costs, and expensive oil separator replacements. Low maintenance requirements make these systems facility manager favorites - magnetic bearings mean parts don't wear out like conventional compressors.

Quiet operation (typically 65 dB or lower) allows installation in locations where traditional compressors would be too noisy.

Why choose turbo air over screw or piston?

Lifecycle savings add up quickly. Energy costs drop 20-30% compared to conventional compressors. Oil costs disappear entirely. Maintenance becomes scheduled rather than emergency-driven.

Footprint reduction matters significantly. Turbo air systems take considerably less space than equivalent screw or piston compressors, especially including supporting equipment.

The smooth, pulsation-free air delivery improves downstream performance - pneumatic controls respond more precisely and processes maintain better consistency.

Potential drawbacks to consider

Higher upfront cost can be two to three times more than conventional alternatives, requiring serious financial justification.

Complexity means sophisticated controls provide excellent performance but require specialized technician training, potentially limiting service options.

Load-profile sensitivity makes these systems prefer steady loads. Frequent start-stop cycles or extreme demand swings can challenge optimal performance.

Surge risk, though manageable with proper controls, represents a potential failure mode that doesn't exist with positive displacement compressors.

At American Mortuary Coolers, turbo air technology works exceptionally well in mortuary applications where consistent performance and hygienic operation are non-negotiable. The key is matching technology to application.

Selecting, Sizing & Maintaining Turbo Air Equipment

Choosing the right turbo air system requires understanding your specific needs, from basic pressure and flow requirements to operating environment details. Unlike traditional compressors that work across broad ranges, centrifugal systems have a "sweet spot" for optimal performance.

Environmental factors significantly impact performance. High altitude reduces air density, extreme temperatures stress components, and corrosive atmospheres require special materials.

ISO purity requirements directly impact system design. While all turbo air systems deliver oil-free air, specific cleanliness standards may require additional filtration stages.

Turbo Air sizing checklist for buyers

Application audit reveals actual compressed air usage patterns. Flow calculation requires accounting for every air user, understanding that not everything runs simultaneously.

Pressure margin of 10-15% above calculated needs provides safety buffer for unexpected pressure drops and future equipment additions.

Modulating demand patterns determine whether facilities have steady needs or challenging demand swings.

Maintenance best practices & expected lifespan

Bearing inspection is simplified with modern systems. Magnetic bearing systems practically maintain themselves, while air bearings need periodic attention but nothing like oil-lubricated systems.

Vibration monitoring has evolved to sophisticated online systems that learn equipment's normal signature and alert when changes occur.

Self-cleaning condenser technology automatically maintains efficiency without manual coil cleaning.

20-year design life is routinely achieved with proper maintenance and following manufacturer recommendations. More info about choosing a walk-in freezer provides insights into selecting long-lasting equipment.

At American Mortuary Coolers, we've learned that the best equipment investments consider the full lifecycle: proper sizing, quality installation, and consistent maintenance deliver optimal value.

Industry Applications & Sustainability Impact

Turbo air systems have revolutionized compressed air across industries. Food processing plants use them for pneumatic conveying and packaging equipment. Pharmaceutical companies rely on documented air quality for FDA compliance. Textile manufacturers need perfectly clean air for high-speed air-jet looms. Mining operations depend on reliable ventilation systems.

How turbo air improves environmental sustainability

Traditional compressed air systems release oil mist and create disposal challenges. Turbo air systems completely eliminate these emissions.

Energy Star statistics show turbo air systems achieve 15-30% higher efficiency than traditional compressors, with over 140 Energy Star certified models available.

Propane (R290) adoption in turbo air refrigeration offers global warming potential of just 0.02 compared to hundreds for traditional refrigerants - a 99% reduction in environmental impact.

The longevity factor matters too. Turbo air systems typically run 20+ years with minimal maintenance while traditional compressors might need replacement multiple times.

Turbo Air in morgue & cold-storage solutions

Mortuary applications require rock-solid temperature control. Turbo air systems provide consistent, reliable operation for these sensitive applications.

Oil-free operation eliminates contamination risks in sterile procedures. At American Mortuary Coolers, our Tennessee-based team has perfected turbo air integration with walk-in mortuary units for customers needing flawless equipment performance.

Our experience serving customers nationwide shows turbo air technology excels in specialized cold storage where reliability is essential, from Chicago's harsh winters to Dallas heat.

Frequently Asked Questions about Turbo Air

What is a turbo air compressor and how does it work?

A turbo air compressor works like a sophisticated high-speed fan. A spinning impeller (over 20,000 RPM) grabs incoming air and flings it outward using centrifugal force. This fast-moving air enters a diffuser with carefully shaped passages that gradually slow the air down, converting kinetic energy into pressure energy.

Turbo air systems don't need oil - they use magnetic bearings or air bearings that float spinning parts without physical contact, ensuring no oil contamination in compressed air.

How do I pick the right turbo air size for my plant?

Start by identifying every compressed air user in your facility. Turbo air systems prefer steady work over stop-and-go operation. Consider future expansion needs and size slightly larger for growth.

Purity requirements matter tremendously. Food processing and pharmaceuticals need ISO 8573-1 Class 0 oil-free air. Environmental factors like temperature, altitude, and humidity affect performance and must be considered.

What maintenance does an oil-free turbo air system require?

Oil-free turbo air systems are low-maintenance workhorses. Monitor bearings (magnetic bearings are practically maintenance-free), check air filters regularly, and keep control systems updated with periodic calibration.

Predictive maintenance capabilities help catch problems before expensive failures. Modern systems provide vibration analysis and thermal monitoring for proactive care.

At American Mortuary Coolers, proper maintenance extends equipment life dramatically across our 48-state service coverage, keeping turbo air systems running smoothly for their full 20-year design life.

Conclusion

Turbo air technology has revolutionized compressed air and refrigeration systems, delivering 100% oil-free operation while improving efficiency and reducing maintenance. Energy savings of 15-30% compared to traditional compressors mean these systems often pay for themselves within years.

The oil-free benefits transform operations - food processors eliminate contamination risks, pharmaceutical manufacturers get validated air purity, and maintenance teams avoid oil-related headaches.

At American Mortuary Coolers, our Tennessee-based team has designed custom cooling solutions across all 48 contiguous states. When funeral homes need consistent temperatures and hygienic conditions, turbo air systems deliver essential reliability.

Environmental impact matters too. These systems eliminate oil emissions and significantly reduce carbon footprints through improved efficiency. With over 140 Energy Star certified models available and natural refrigerants gaining traction, turbo air represents genuinely sustainable choices.

Your next steps should assess current compressed air needs, energy bills, maintenance costs, and air quality requirements. Consider future expansion and whether existing systems can handle growth.

Work with suppliers who understand both the technology and your specific application. Turbo air technology requires expertise for proper selection and avoiding costly mistakes.

Turbo air technology isn't just another compressor option - it's often the best solution for demanding applications where conventional systems can't deliver the performance, efficiency, and reliability modern operations require.

Ready to explore how turbo air technology might transform your facility? More info about commercial refrigeration solutions can help you understand the broader picture and make informed equipment investment decisions.