A Quick Start Guide to R404A Pressure Charts and Values

Why R404A Pressure Charts Are Essential for Mortuary Equipment

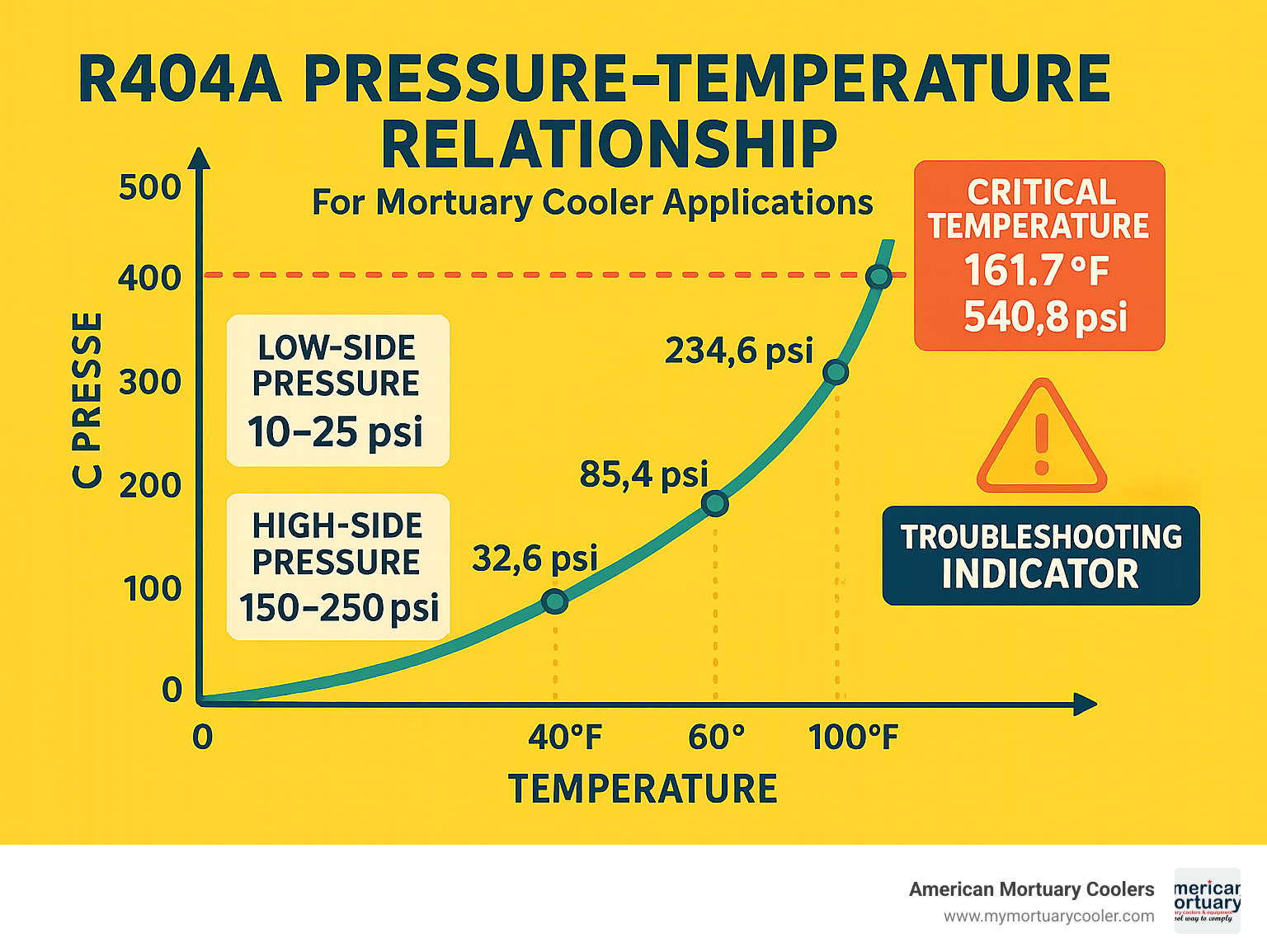

404a pressure chart data shows the exact relationship between temperature and pressure for R404A refrigerant systems. Here's what you need to know:

Key R404A Pressure Values:

- 0°F (-17.8°C): 32.6 psi

- 40°F (4.4°C): 85.4 psi

- 100°F (37.8°C): 234.6 psi

- Critical limits: 540.8 psi max, 161.7°F critical temperature

Normal Operating Ranges:

- Low-side pressure: 10-25 psi (suction)

- High-side pressure: 150-250 psi (discharge)

- Pressure increase: 5-7 psi per 5°F temperature rise

R404A is the backbone refrigerant for most commercial walk-in coolers and freezers, including mortuary equipment. This HFC blend of R-125, R-143a, and R-134a delivers reliable low-temperature performance that funeral homes depend on.

Understanding pressure-temperature relationships is critical because even small pressure changes signal major system issues. A stuck expansion valve, low refrigerant charge, or dirty condenser can throw these numbers off - leading to equipment failure when you need it most.

As one HVAC technician noted in a forum discussion: "Most small reach-in 404a freezers run about 10 psi low side and 175 psi head average." These baseline numbers help you spot problems before they become costly repairs.

The pressure chart serves as your diagnostic roadmap - matching measured pressures to expected temperatures reveals everything from refrigerant leaks to compressor problems. Without this reference, you're troubleshooting blindfolded.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes maintain their refrigeration systems using 404a pressure chart data for optimal performance. My background includes working directly with funeral directors across the country to solve complex cooling challenges and ensure reliable mortuary equipment operation.

Simple 404a pressure chart glossary:

Understanding R404A Refrigerant Basics

Think of R404A as a carefully crafted recipe - it's a blend of three different refrigerants mixed in precise proportions. The formula includes 44% R-125, 4% R-134a, and 52% R-143a. This HFC (hydrofluorocarbon) combination has earned its reputation as the go-to choice for commercial refrigeration, especially in funeral homes where reliability isn't negotiable.

What makes R404A special for mortuary applications? Its critical temperature of 161.7°F sets the absolute ceiling for safe operation. Push your system beyond this point, and you're asking for trouble. The critical pressure of 540.8 psi serves as another crucial safety boundary that every technician needs to respect.

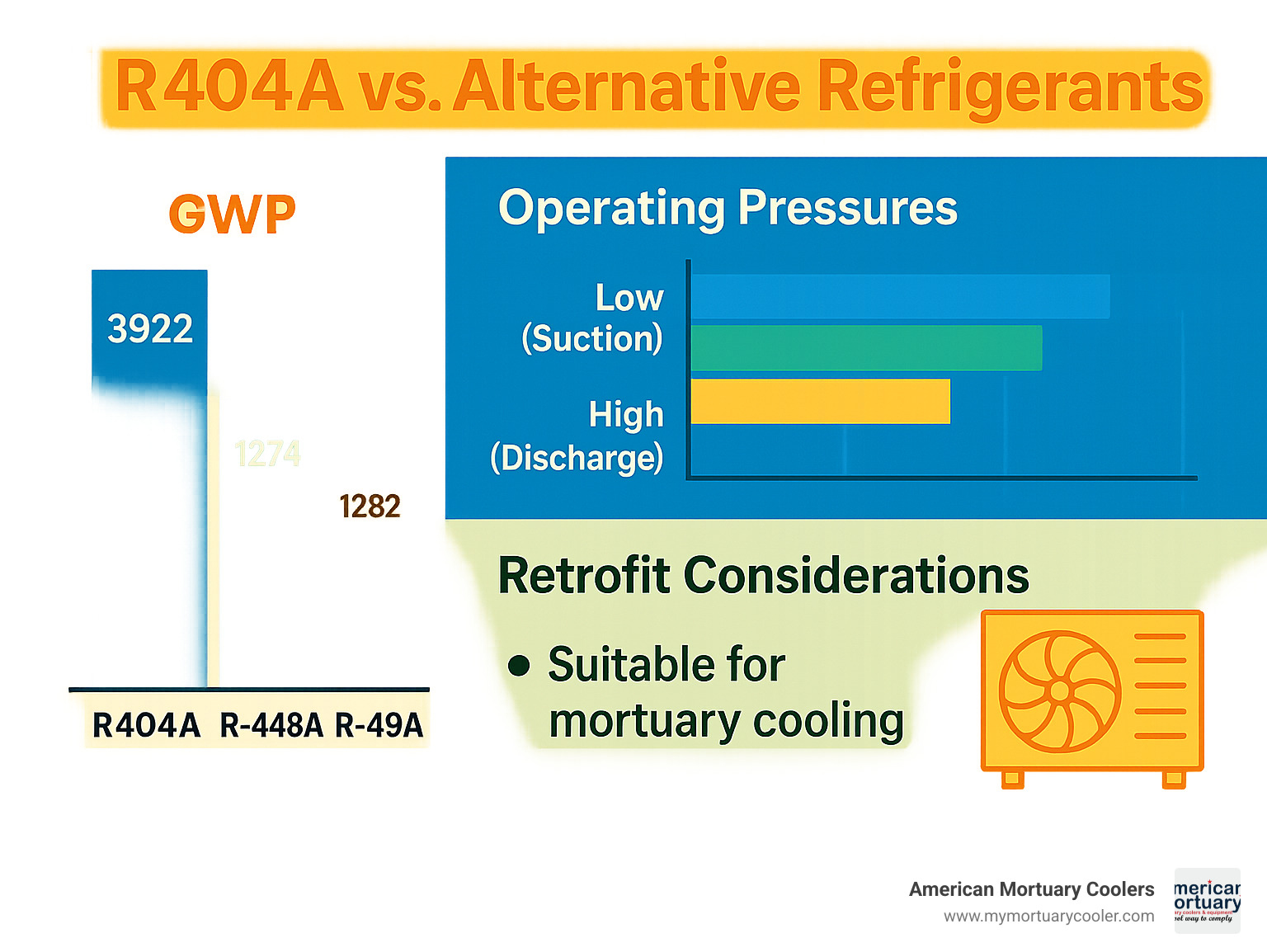

Here's where things get interesting from an environmental perspective. R404A carries a Global Warming Potential (GWP) of 3,922 - a number that's caught the attention of regulators worldwide. This means we're seeing a gradual phase-out of HFC refrigerants like R404A in favor of more eco-friendly alternatives.

For funeral home operators, this creates a balancing act. You need equipment that works flawlessly today while planning for tomorrow's regulations. That's why understanding your current system's refrigerant becomes even more important when making maintenance and replacement decisions.

The heart of your cooling system - the compressor - works hand-in-hand with R404A to maintain those critical low temperatures. More info about compressor function can help you understand this relationship better and spot potential issues before they become expensive problems.

Key Properties & Uses

R404A shines brightest in supermarket frozen food cases and walk-in freezers where consistent sub-zero temperatures are non-negotiable. Its boiling point of -51.88°F makes it perfect for applications that need to stay well below freezing - exactly what mortuary coolers require.

In mortuary cooler applications, R404A provides the steady, reliable performance that funeral directors depend on. Whether you're dealing with a busy week or equipment that sits idle for days, this refrigerant maintains stable pressures and temperatures without drama.

Walk-in coolers and freezers represent the bread and butter of R404A applications. These systems handle the constant challenge of door openings, product loading, and temperature recovery - all while maintaining the precise conditions your facility requires.

Bubble vs Dew Fundamentals

Unlike simple refrigerants that change from liquid to vapor at one specific temperature, R404A is what we call a zeotropic blend with temperature glide. This means it changes phase gradually over a small temperature range rather than all at once.

The bubble point marks where the first vapor bubble appears as liquid starts to boil. The dew point represents where the last liquid droplet forms as vapor condenses. This azeotrope glide might seem like technical mumbo jumbo, but it directly affects how you charge and service your system.

When you're working with a 404a pressure chart, you'll notice separate columns for liquid (bubble point) and vapor (dew point) readings. This distinction matters when you're calculating superheat and subcooling values - get it wrong, and your diagnostic readings won't make sense.

This phase change science also explains why proper charging technique matters so much with blended refrigerants. Always charge liquid to prevent fractionation - drawing vapor from the cylinder can mess up the blend composition and throw off your pressure readings completely.

Decoding the 404a Pressure Chart

When you first look at a 404a pressure chart, it might seem overwhelming with all those numbers and columns. But once you understand the layout, it becomes your best friend for diagnosing refrigeration problems.

Every professional pressure-temperature chart shows temperature values in both Fahrenheit and Celsius alongside their matching pressure readings in psig (pounds per square inch gauge). Think of it as a translation guide - you give it a pressure reading, and it tells you what temperature that represents.

Here's where R404A gets a bit tricky compared to simpler refrigerants. Since it's a blend, you'll see separate columns for liquid and vapor pressures. At 0°F, for example, the liquid pressure sits at about 32.6 psig while the vapor pressure runs slightly lower. This gap widens as temperatures climb higher.

Most quality charts cover everything from sub-atmospheric conditions (shown in inches of mercury below atmospheric pressure) all the way up to 150°F or beyond. For mortuary work, you'll spend most of your time in the -20°F to 40°F range, where every psi counts for accurate diagnosis.

The R-404A Pressure Temperature Chart – HVAC Buddy® offers an excellent interactive reference that works great on your phone during service calls. No more squinting at worn paper charts in dim equipment rooms.

| Temperature (°F) | Liquid Pressure (psig) | Vapor Pressure (psig) |

|---|---|---|

| -20 | 18.1 | 17.2 |

| 0 | 32.6 | 31.4 |

| 20 | 52.8 | 51.2 |

| 40 | 79.3 | 77.1 |

How to read a 404a pressure chart

Reading these charts becomes second nature once you understand the column layout. Temperature always appears in the leftmost columns (usually both °F and °C), followed by liquid pressure, then vapor pressure. Some charts throw in extra data like liquid density or heat content, but stick to the basics when you're starting out.

The process is straightforward: locate your measured pressure in the right column, then read across to find the matching saturation temperature. For superheat calculations, always use the vapor pressure column. For subcooling work, stick with the liquid pressure column.

Interpolation saves the day when your measured pressure falls between chart values. Say you measure 45 psig and the chart shows 40 psig at 15°F and 50 psig at 22°F. Your saturation temperature lands at approximately 18.5°F - right in the middle.

Before you trust any reading, make sure your pressure gauge is properly calibrated and zeroed. A 2-3 psi gauge error can lead you down the wrong diagnostic path, especially in low-pressure applications common in mortuary coolers.

Common mistakes with a 404a pressure chart

The biggest mistake we see technicians make is ignoring ambient temperature effects on pressure readings. A condenser running in 95°F summer heat will show much higher head pressures than the same system in comfortable 75°F conditions. This isn't broken equipment - it's physics doing its thing.

Altitude corrections trip up many technicians, especially those working in mountainous areas. Pressure readings at higher elevations need adjustment since atmospheric pressure drops with altitude. Most charts assume sea-level conditions, so mountain installations require correction factors.

Mixing pressure units creates confusion and potential safety hazards. Always confirm you're reading psig (gauge pressure) not psia (absolute pressure). The difference is atmospheric pressure - about 14.7 psi at sea level. Mix these up, and your calculations go sideways fast.

Fractionation in blends like R404A can throw off pressure readings if someone has serviced the system incorrectly. Always charge with liquid and avoid topping off with vapor to keep the blend composition intact. Once fractionation occurs, your 404a pressure chart readings become unreliable.

Using PT Charts for Diagnostics & Optimization

Here's where the 404a pressure chart becomes your best friend in the field. Those numbers on your gauges mean nothing without the chart to translate them into real-world temperatures and system health indicators.

Let's say you're checking a mortuary cooler and your suction gauge reads 15 psi. The pressure chart tells you that refrigerant is saturated at about -7°F. Now measure the actual temperature of your evaporator coil - if it's reading -2°F, you've got 5°F of superheat. That's right in the sweet spot for most systems.

Charge verification becomes crystal clear when you know how to read these pressure relationships. An undercharged system will show you low suction pressures paired with high superheat readings. Meanwhile, an overcharged system does the opposite - high head pressures with little to no subcooling. The chart gives you the baseline numbers to spot these problems immediately.

Energy efficiency depends heavily on maintaining proper pressure relationships throughout your system. When superheat and subcooling values stay within normal ranges, your compressor doesn't have to work as hard. For mortuary applications where consistent temperatures are absolutely critical, this efficiency translates to reliable operation and lower utility bills.

Leak detection becomes much easier with pressure chart data too. A slow leak will gradually lower your suction pressures over time. Regular pressure readings compared to chart values help you catch these issues before they become emergency service calls.

For more detailed information about how these components work together, check out our comprehensive guide on walk-in compressors.

Setting Correct Pressures in Coolers & Freezers

Most R404A mortuary coolers should run with suction pressures between 10-25 psi for proper low-temperature operation. This pressure range corresponds to evaporator temperatures from roughly -20°F to 0°F - exactly what you need for safe body storage.

Head pressures typically fall between 150-250 psi, depending on how hot it is outside and how clean your condenser coils are. A well-maintained system in moderate weather (75-85°F) should hold steady around 175-200 psi on the high side.

Don't panic when pressures spike temporarily after a busy day. Product loading has a huge impact on system pressures. When a funeral home receives several cases at once, that extra thermal load will push suction pressures higher as the system works overtime to remove heat. This is completely normal - not a sign of trouble.

Pressure control settings need careful attention based on your specific application. Low-pressure controls should cut out around 3-5 psi and restart at 15-20 psi. High-pressure controls protect your equipment while allowing for normal temperature swings throughout the day.

Troubleshooting With PT Data

Overcharge symptoms show up clearly in your pressure readings. High head pressures, minimal subcooling, and that scary liquid slugging sound all point to too much refrigerant. The pressure chart helps you quantify exactly how far off your readings are from normal values.

Undercharge presents the opposite picture - low suction pressures, excessive superheat, and poor cooling performance. When your chart shows suction pressures consistently below normal ranges, you're looking at a refrigerant shortage.

Restricted expansion valves create a tricky situation where you see high superheat but normal or even low suction pressures. The pressure chart helps you differentiate between a charge problem and a stuck TXV by showing whether your pressure-temperature relationships make sense.

Iced evaporators cause their own unique pressure signature - low suction pressures combined with high superheat as ice blocks airflow and reduces heat transfer efficiency. If ice buildup is plaguing your system, our detailed guide on How to Fix an Iced Evaporator walks you through proven solutions.

The key is learning to read the story your pressures are telling you. Every system has its own personality, but the 404a pressure chart gives you the foundation to understand what's normal and what needs attention.

Safe Operating Pressures, Ambient Effects & Troubleshooting

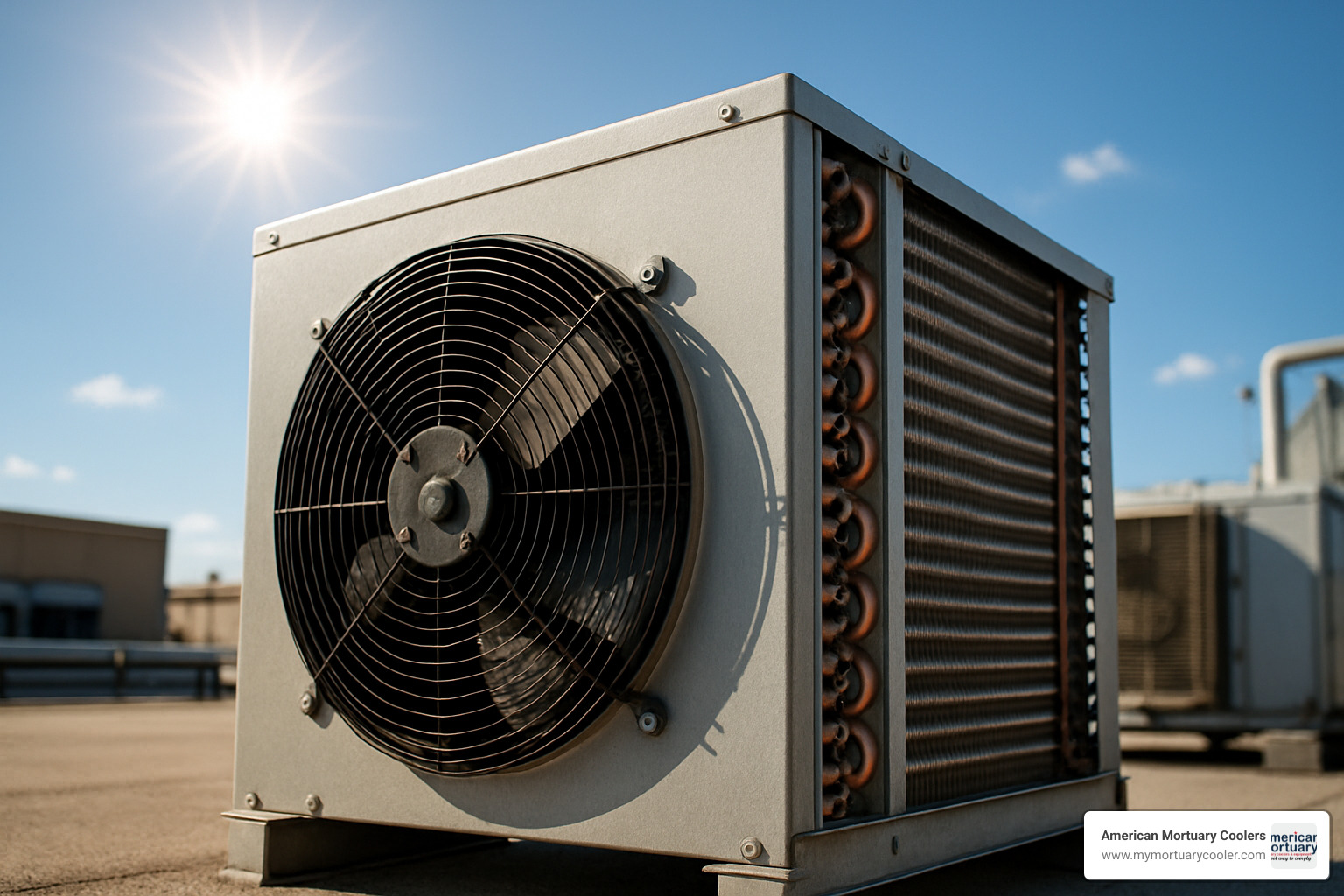

Summer heat can turn a perfectly functioning mortuary cooler into a problem child. When that condenser sits baking in 100°F sunlight, your 404a pressure chart readings will tell a very different story than they did during spring installation.

Here's the reality: ambient temperature swings hit R404A systems hard. For every 5°F increase in outdoor temperature, expect head pressures to climb 5-7 psi. That condensing unit that ran beautifully at 175 psi in March might be pushing 220 psi come July - and that's completely normal.

This relationship becomes especially important for funeral homes where equipment reliability can't be compromised. Your outdoor condensing units face brutal seasonal swings, while indoor units deal with whatever your building's HVAC system throws at them. Understanding these pressure variations prevents unnecessary service calls and helps you spot real problems.

The critical pressure limit of 540.8 psi represents the danger zone for R404A systems. Think of it as the red line on your car's tachometer - you never want to get close. Most systems include pressure relief devices and safety controls set well below this limit, typically around 450-500 psi for high-side protection.

Working with pressurized refrigerant systems demands respect and proper safety equipment. Safety glasses, gloves, and appropriate clothing protect against refrigerant exposure that can cause severe frostbite or eye injury. High-pressure systems carrying 200+ psi pack enough force to cause serious harm if connections fail.

Recovery procedures become more complex in hot weather because systems operating at higher ambient temperatures contain more refrigerant in the condenser. This affects recovery quantities and timing. Always follow EPA guidelines for refrigerant recovery and recycling - the regulations exist for good reasons.

Pressure Limits & Safety Precautions

Every R404A system includes multiple layers of pressure protection, starting with burst discs and pressure relief valves. These safety devices act like circuit breakers for your refrigeration system, venting refrigerant before pressures reach dangerous levels.

Your pressure gauges need to match your system's operating range with adequate safety margin. Low-side gauges typically handle 0-100 psi, while high-side gauges cover 0-500 psi. Using an underrated gauge is like bringing a butter knife to a sword fight - it won't end well.

R404A systems use POE (polyolester) oil, which creates its own handling challenges. This synthetic lubricant acts like a sponge for moisture, requiring deep vacuum evacuation to 400 microns or less. Moisture contamination affects both oil performance and system pressures, creating problems that show up on your pressure readings.

Never exceed manufacturer specifications during pressure testing. Over-pressurization can damage components and create safety hazards that put people at risk. When in doubt, consult equipment documentation for maximum test pressures.

Ambient Temperature Corrections

Most 404a pressure charts assume you're working at sea level with standard atmospheric pressure. If you're installing systems in Denver or other high-altitude locations, those pressure readings need correction factors since atmospheric pressure drops with elevation.

Condenser cleanliness makes a huge difference in pressure readings. A dirty condenser works harder to reject the same amount of heat, pushing head pressures higher than normal. Regular cleaning maintains proper pressure relationships and keeps energy costs reasonable.

Seasonal operation creates its own challenges. Winter operation may require head pressure control to maintain proper refrigerant flow through the expansion valve. Summer operation focuses on high-pressure protection to prevent nuisance shutdowns during peak ambient conditions.

Indoor installations face unique ambient challenges that outdoor charts don't address. Mechanical rooms with poor ventilation can create artificially high ambient temperatures, leading to liftd system pressures that look like equipment problems but are really ventilation issues.

Frequently Asked Questions about 404A Pressure Charts

When you're working with R404A systems day in and day out, the same questions keep popping up. Let me share the answers I give most often to funeral home operators and technicians who want to get their mortuary coolers running perfectly.

These aren't textbook answers - they're real-world guidance based on years of installing and servicing mortuary equipment across the country.

What pressure should R404A run at in a walk-in cooler?

Here's the short answer: suction pressures between 10-25 psi and discharge pressures from 150-250 psi cover most walk-in cooler situations. But let me give you the details that actually matter.

Your suction pressure depends entirely on how cold you need that cooler. A mortuary cooler running at 0°F needs about 32 psi suction pressure according to the 404a pressure chart. Drop that temperature to -10°F for longer-term storage, and you're looking at closer to 20 psi suction.

The discharge side tells a different story. Clean condensers in normal 80°F conditions should hold 175-200 psi head pressure. When summer hits and that condenser's baking in 95°F heat, don't panic if you see 225 psi - that's just physics at work.

I always tell funeral directors to expect pressure variations. When you're loading multiple cases after a busy weekend, those suction pressures will climb temporarily as the system works harder. That's normal operation, not a breakdown waiting to happen.

How do I calculate superheat with a 404a pressure chart?

Superheat calculation sounds complicated, but it's actually straightforward once you understand the process. You need two measurements: suction line temperature and suction pressure.

Here's how it works in practice. Let's say you measure 15 psi suction pressure and your suction line temperature reads 5°F. Look up 15 psi in the vapor pressure column of your 404a pressure chart - that shows saturation at approximately -7°F.

Your superheat calculation becomes simple math: 5°F minus (-7°F) equals 12°F of superheat. That's a healthy reading for most mortuary cooler applications.

The key detail most people miss is using the dew point (vapor) column for superheat calculations, never the bubble point column. R404A is a blend, so those numbers differ slightly. Using the wrong column throws off your entire diagnosis.

Most mortuary coolers run best with 8-12°F of superheat. Too little suggests overcharge or expansion valve problems. Too much indicates undercharge or restricted refrigerant flow.

Is R404A being phased out and what are alternatives?

This question comes up in every conversation lately, and I understand the concern. R404A isn't disappearing overnight, but regulations are definitely pushing toward lower-impact alternatives.

The issue is R404A's Global Warming Potential of 3,922 - that's a big number in today's environmental landscape. While you can still buy it and service existing systems, new regulations favor alternatives for fresh installations.

R-448A and R-449A represent your best retrofit options for existing mortuary coolers. Both offer dramatically lower GWP values (1,274 and 1,282 respectively) while maintaining similar cooling performance. The transition isn't always plug-and-play, though.

Retrofit procedures require attention to charging methods and pressure control adjustments. Some expansion valves need recalibration, and pressure relief devices might need updating. It's not a weekend DIY project - bring in qualified technicians for the conversion.

For funeral homes planning new installations, we're seeing increased interest in CO2 systems and other natural refrigerants. These options eliminate future regulatory concerns while often providing superior performance.

The bottom line? Keep maintaining your existing R404A systems - they'll serve you well for years to come. But start planning for alternatives when major equipment replacement comes up.

Conclusion

The 404a pressure chart is your best friend in the refrigeration world. It transforms confusing gauge readings into clear diagnostic information that helps you fix problems fast and keep systems running smoothly.

Think of it this way - without the chart, you're trying to steer in the dark. With it, you have a roadmap that shows exactly where your system stands and where it needs to go. Every successful repair starts with accurate pressure-temperature data.

We've watched countless technicians struggle with mortuary cooler problems until they learned to trust their pressure charts. Once they mastered this simple tool, their troubleshooting became faster, more accurate, and way less stressful.

System longevity depends on proper pressure management. Overcharged systems work too hard. Undercharged systems can't keep up. The chart helps you find that sweet spot where everything runs efficiently and lasts longer.

At American Mortuary Coolers, we build our custom walk-in solutions with these pressure-temperature principles in mind. From Tennessee to funeral homes across all 48 contiguous states, we've seen how proper pressure management makes the difference between reliable equipment and costly headaches.

The refrigeration industry keeps changing with new regulations and refrigerant alternatives. R404A might eventually give way to lower-GWP options. But here's the thing - pressure-temperature relationships stay the same. Master these fundamentals now, and you'll adapt easily to whatever comes next.

Planning a new mortuary cooler or upgrading your current setup? Our Ultimate Guide to Walk-In Cooler Features and Prices covers everything you need to know about making smart equipment decisions.

Keep that 404a pressure chart handy. Learn to read it like a pro. Trust the numbers it gives you. Your equipment will thank you with years of reliable service, and your stress levels will thank you too.

The difference between guessing and knowing is just a chart away. Make it count.