All About Autopsy Carts: Top Products for Your Lab

Why Professional Autopsy-Carts Are Essential for Modern Pathology Labs

An autopsy-cart is a specialized mobile platform designed to transport, position, and support human remains during post-mortem examinations. These stainless steel carts feature built-in fluid drainage systems, heavy-duty casters, and ergonomic designs that integrate seamlessly with autopsy sinks and examination workflows.

Key Autopsy-Cart Features:

- Construction: 14-16 gauge type 304 stainless steel

- Dimensions: Standard 32" × 80" (bariatric up to 40" wide)

- Capacity: 500-750 lb weight rating

- Mobility: 8" total-lock casters with directional steering

- Drainage: Built-in slopes with removable drain plugs

- Height: Fixed (34-35") or adjustable (22"-37.5")

Modern pathology labs rely on these specialized carts to maintain sterile conditions while providing forensic pathologists with safe, efficient access to remains. The sloped surfaces channel fluids directly into autopsy sinks, while heavy-duty construction ensures stability during detailed examinations.

Proper equipment selection directly impacts workflow efficiency and safety compliance in morgue environments. Research shows that autopsy carts with integrated fluid management systems reduce contamination risks and streamline cleaning protocols between cases.

As a national-level mortuary cooler supplier with experience in morgue equipment, we've helped countless pathology labs select the right autopsy-cart configurations for their specific workflows and space constraints.

Simple guide to autopsy-cart terms:

What Is an Autopsy Cart and Why Every Pathology Lab Needs One

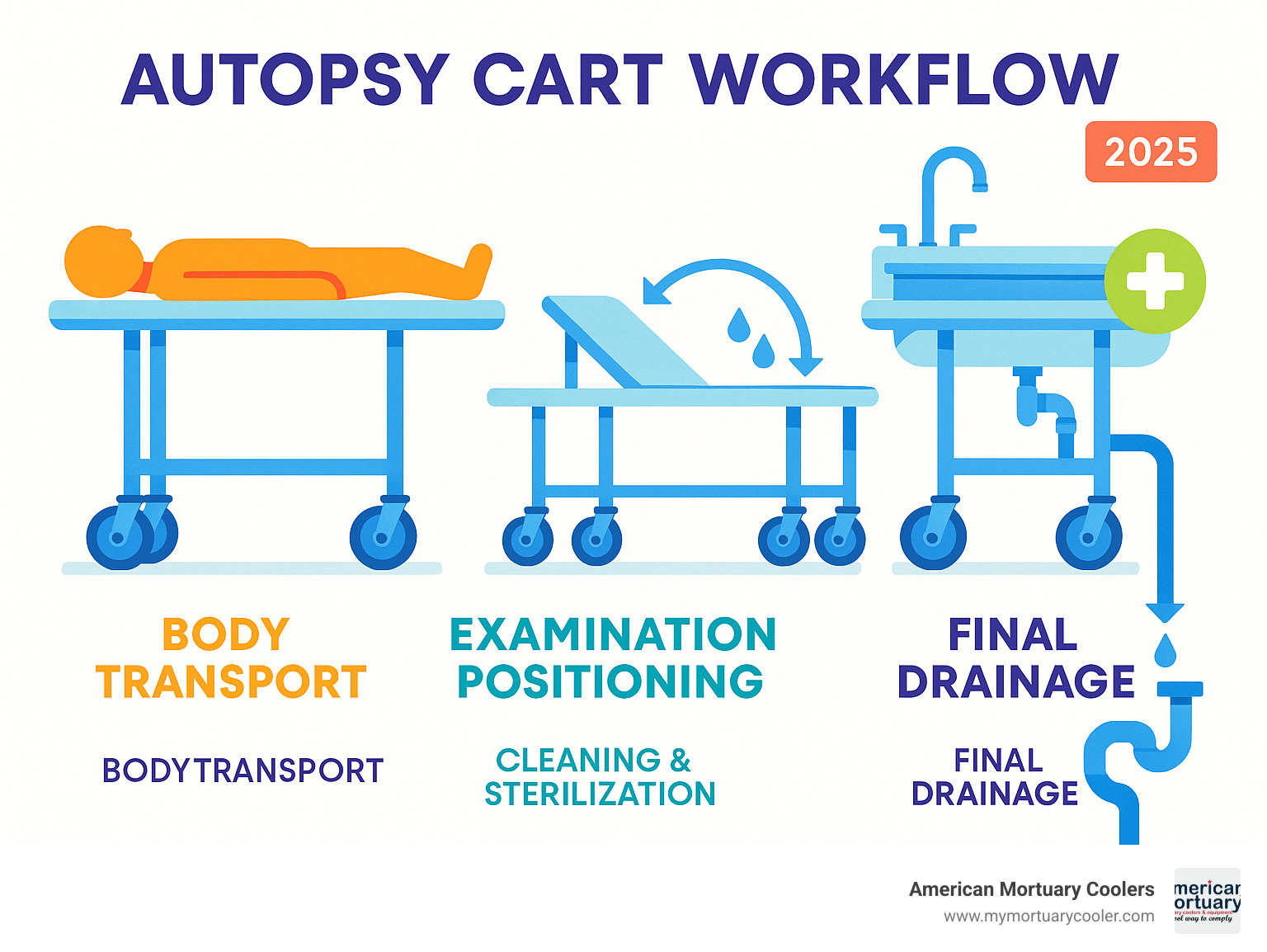

An autopsy-cart does much more than just move things around. It's the workhorse that handles body transport from storage to examination areas, then transforms into a stable examination platform where pathologists can work safely and efficiently. The real magic happens when you roll it over to your autopsy sink - these carts are designed with perfect compatibility that creates one seamless workspace.

Workflow efficiency improves dramatically with the right autopsy-cart. The built-in drainage slopes channel fluids directly where they need to go, while the heavy-duty wheels let you position everything exactly where you need it.

Safety isn't just a nice-to-have - it's absolutely critical. These carts support up to 500 pounds without breaking a sweat, and the total-lock brake system means nothing moves unless you want it to. Your staff can focus on their important work instead of worrying about equipment failure.

Scientific research on autopsy techniques backs this up. Labs using professional-grade carts see fewer injuries and more consistent results.

Autopsy-Cart History & Evolution

Autopsy carts have evolved from early fixed trolleys - basically wooden carts that could barely handle basic transport. These primitive setups had no drainage, absorbed contamination, and fell apart quickly.

The stainless-steel revolution changed everything in the 1960s. Type 304 stainless steel became the gold standard because it fights off corrosion and stays sanitary through countless cleaning cycles.

Height-adjustable designs represent the newest evolution. Modern carts adjust from 22 inches all the way up to 37.5 inches, whether using hydraulic systems or simple hand cranks. This flexibility has become essential as forensic work has gotten more detailed and specialized.

Core Features & Components of a Modern autopsy-cart

When you're investing in an autopsy-cart, you're really investing in precision engineering. Every component serves a specific purpose, and understanding these features helps you make the right choice for your lab.

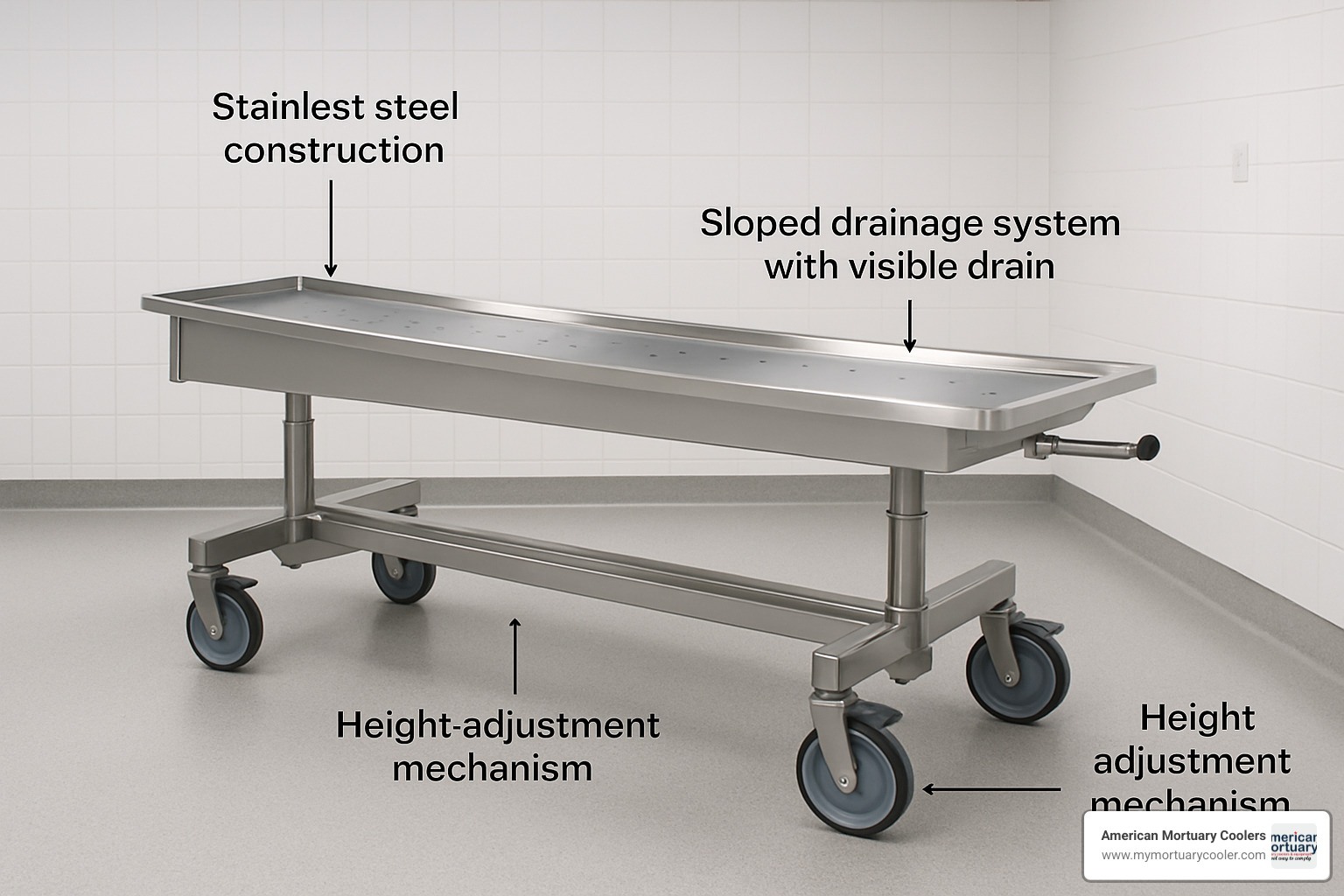

The heart of any quality autopsy cart starts with 14-16 gauge type 304 stainless steel construction. This specific steel grade handles the daily assault of chemicals, biological fluids, and intensive cleaning without breaking down. The thickness gives you the strength needed for heavy loads while keeping the cart light enough to maneuver easily.

That recessed top surface isn't flat by accident. Engineers carefully calculate the slope to guide every drop of fluid toward the drain holes. No puddles, no mess, and most importantly, no cross-contamination between cases.

The 8-inch total-lock casters deserve special attention because they're doing heavy lifting - literally. Three wheels lock completely to prevent any movement during procedures, while the fourth wheel includes directional control for precise positioning. Those polyamide hubs and polyurethane treads resist chemical damage and roll quietly across morgue floors.

Height adjustment varies depending on your needs and budget. Fixed models sit at 34-35 inches, while adjustable versions span 22 to 37.5 inches. Hand-crank systems give you 6 inches of travel, but hydraulic models offer infinite adjustment within their range.

Weight capacity typically hits 500 pounds for standard models, jumping to 750 pounds for bariatric versions. These account for the dynamic forces during examinations and transport, not just static weight.

| Model Type | Height Range | Weight Capacity | Width Options | Key Features |

|---|---|---|---|---|

| Fixed | 34-35" | 500 lbs | 32" standard | Basic drainage, total-lock casters |

| Hydraulic | 22-37.5" | 500 lbs | 32", 36" | Foot-pump adjustment, ergonomic rails |

| Bariatric | 29.5-37.5" | 750 lbs | 32-40" | Hand-crank height, reinforced frame |

Materials & Build Quality

Type 304 stainless steel is the only standard that makes sense for morgue equipment. This specific alloy handles harsh chemicals and biological fluids that would destroy lesser materials. The 14-16 gauge thickness gives you structural integrity without making the cart too heavy.

The welded construction eliminates every joint and seam where bacteria love to hide. Professional welding creates smooth, seamless surfaces that make thorough cleaning possible.

Polyamide plastic hubs in the caster wheels resist chemical damage that would eat through standard materials. Polyurethane treads maintain their integrity while rolling smoothly and quietly across any morgue flooring.

Autopsy-Cart Dimensions & Load Ratings

The standard 32 inches wide by 80 inches long dimensions represent decades of real-world morgue experience, ensuring compatibility with existing autopsy sinks while providing adequate workspace.

Bariatric models extend up to 40 inches wide to accommodate larger cases. Load ratings of 500 pounds for standard models and 750 pounds for bariatric versions include generous safety margins for dynamic forces during movement and examination.

Drainage & Hygiene Engineering

Built-in slopes represent sophisticated fluid management engineering. The precise 1-2 degree angle channels all liquids toward drain points without creating stagnant pools where contamination develops.

Removable drain plugs on chains prevent the frustration of lost plugs during procedures. Seamless welded construction eliminates bacterial hiding spots that plague inferior designs.

Mobility: Casters, Brakes & Steering

Eight-inch heavy-duty wheels provide the perfect balance of load capacity and maneuverability. Total-lock brake systems secure both wheel rotation and swivel movement, preventing any cart movement during delicate procedures.

Directional lock features allow one wheel to maintain straight-line tracking while others provide steering control. This system simplifies transport through narrow corridors and enables precise positioning next to autopsy sinks.

Configurations, Trays & Integration With Other Morgue Equipment

The true value of a professional autopsy-cart emerges through its integration with other morgue equipment. Modern carts function as part of a coordinated system rather than standalone units, creating seamless workflows that improve both efficiency and safety.

Roller frame systems accommodate multiple tray widths, from 24.25-inch MT1 trays to 36.25-inch MT4 configurations. These roller systems distribute weight evenly while allowing smooth tray insertion and removal.

Saddle-type tray supports offer an alternative mounting system for facilities preferring fixed positioning. Fixed tabletop configurations with marine edges eliminate tray systems entirely, creating a permanent examination surface.

The JC100 and JC101 body trays represent industry-standard accessories that integrate seamlessly with most professional autopsy carts. GA100 cart tops provide additional surface area and specialized features for specific examination requirements.

Concealed transport carts combine autopsy functionality with discrete body transport capabilities. The SR1867 series offers full tilt and height adjustability while maintaining a professional appearance suitable for public areas.

More info about morgue gurney options provides detailed guidance on selecting compatible transport equipment.

All About Mortuary Body Trays – Compare Top Options offers comprehensive comparisons of tray systems and their compatibility with different cart configurations.

Matching Your Autopsy-Cart to Body Trays & Sinks

Width alignment between carts, trays, and sinks determines workflow efficiency and safety. Standard 32-inch cart widths accommodate most wall-mounted autopsy sinks, but verification of specific dimensions prevents costly compatibility issues.

Transfer rollers facilitate smooth tray movement between carts and storage systems. Quick-connect clamps secure trays to carts during transport and examination procedures.

Proper sink integration requires precise height matching and drainage alignment. The cart's built-in slope must align with the sink's drainage system to ensure complete fluid management.

Height-Adjustable & Bariatric Variants

Hand-crank mechanisms provide 6 inches of height adjustment through simple manual operation. Hydraulic foot pump systems enable infinite height adjustment within their range while keeping hands free for other tasks.

Electric lift systems represent the premium option, offering push-button height adjustment with precise positioning memory. Bariatric widths from 32 to 40 inches accommodate larger remains while maintaining structural integrity and mobility.

Safety, Ergonomics, Maintenance & Compliance

Working in a morgue environment presents unique challenges that proper autopsy-cart design can help address. When pathologists spend hours conducting detailed examinations, every aspect of the cart's design impacts their comfort and safety.

Proper operator posture starts with the right height adjustment. Being able to position the cart at the optimal working height prevents the back strain and shoulder fatigue that plague morgue workers. The adjustable height capabilities aren't just a convenience - they're essential for maintaining good ergonomics during long procedures.

Foot-clearance frames prevent painful encounters with the cart base when you're focused on your work. Non-slip surfaces on handles and contact points maintain secure grip even when surfaces become wet or contaminated.

ANSI and OSHA guidelines establish the minimum safety standards that all morgue equipment must meet. Professional autopsy carts exceed these requirements through thoughtful design and robust construction.

Daily inspection checklists catch potential problems before they become safety hazards. Preventative maintenance intervals depend on your facility's usage patterns. High-volume morgues typically schedule quarterly maintenance, while smaller facilities might extend this to semi-annual service.

Cleaning & Sterilization Workflow

The cleaning process follows a systematic approach that ensures complete decontamination between cases. Thorough rinsing comes first, removing gross contamination and biological debris before it can harden.

Enzymatic wash solutions tackle the protein-based contamination that standard detergents leave behind. These specialized cleaners break down biological materials at the molecular level.

High-pressure sanitation provides the mechanical action needed to dislodge stubborn contamination. The combination of appropriate pressure and cleaning agents achieves the hospital-grade cleanliness required for forensic work.

Proper drying prevents water spots and eliminates the moisture that bacteria need to grow. Record keeping documents each cleaning cycle and identifies any equipment issues found during the process.

A Comprehensive Guide to Comparing Embalming Tables provides additional insights into cleaning protocols for related morgue equipment.

Routine Service & Warranty Considerations

Caster lubrication keeps everything rolling smoothly and prevents premature wear. Hydraulic seal checks prevent the fluid leaks that could compromise height adjustment systems.

Typical 1-year warranties cover manufacturing defects and premature component failure. Quality manufacturers stand behind their products with comprehensive warranty coverage that includes both parts and labor.

Optional extended support programs provide ongoing maintenance and priority service response. These programs make particular sense for high-volume facilities where equipment downtime directly impacts daily operations.

Innovations & Future Trends in Autopsy-Cart Design

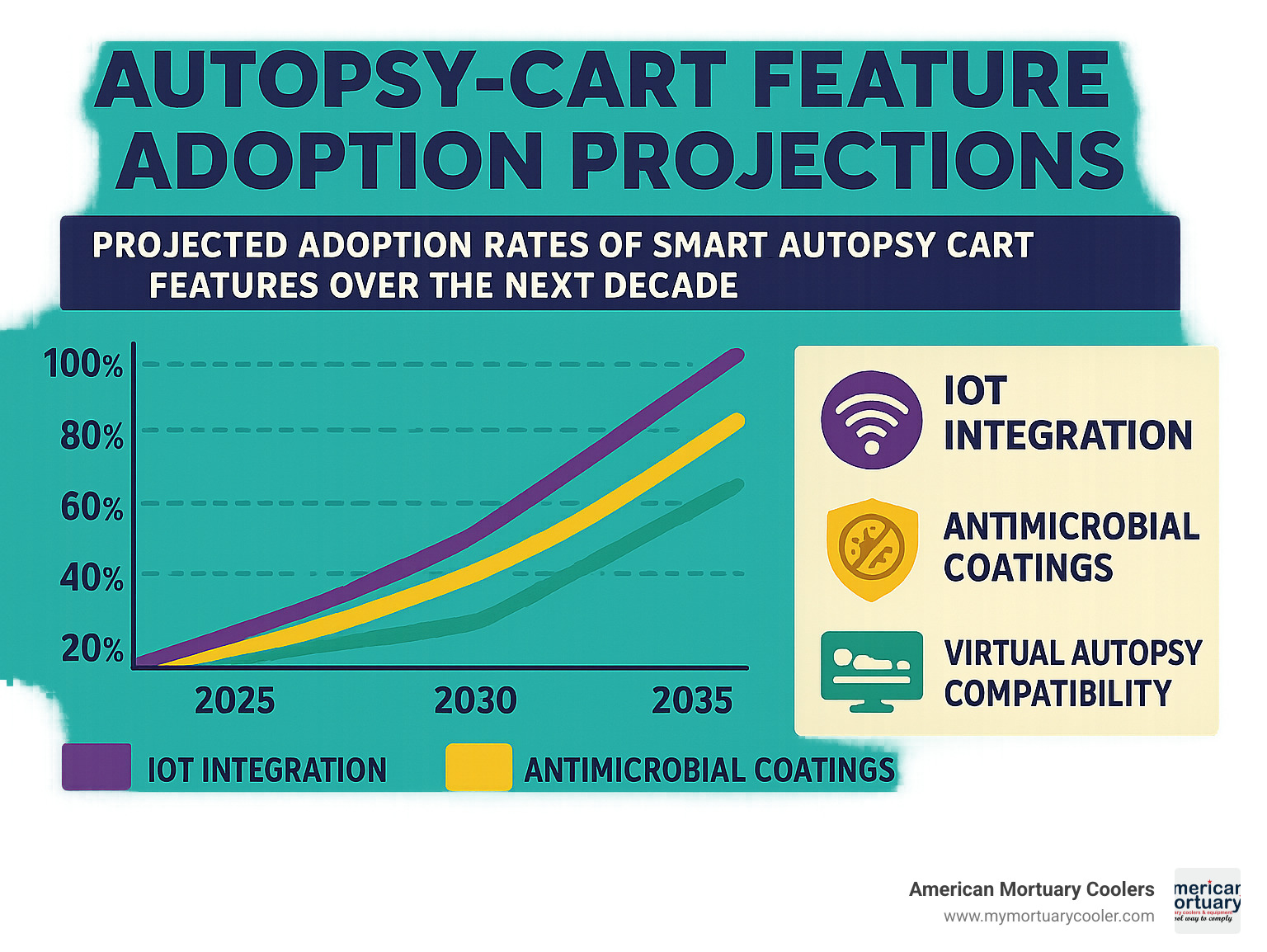

The world of autopsy-cart technology is evolving faster than ever before. What once seemed like science fiction is now becoming standard equipment in forward-thinking pathology labs across the country.

Powered lift systems are revolutionizing how we think about height adjustment. Instead of cranking handles or pumping hydraulic pedals, pathologists can now adjust cart height with the push of a button. These systems provide incredibly precise positioning - we're talking millimeter accuracy - which makes a huge difference during delicate procedures.

Integrated scale systems eliminate the need for separate weighing equipment entirely. The cart itself becomes a precision scale, providing real-time weight data that automatically syncs with digital documentation systems. This isn't just convenient - it's a game-changer for maintaining accurate forensic records.

The rise of IoT load sensors brings predictive maintenance into the morgue. These smart sensors monitor cart performance 24/7, alerting maintenance teams before problems become equipment failures. Imagine never having a cart break down in the middle of an important examination again.

Antimicrobial coatings represent one of the most exciting developments in surface technology. These specialized treatments actively fight bacterial growth between cleaning cycles, adding an extra layer of protection against contamination. The coatings are invisible and don't affect the cart's appearance or cleanability.

Virtual-autopsy compatibility ensures your equipment investment remains relevant as forensic technology advances. Modern carts accommodate the precise positioning requirements for CT scanning and other non-invasive examination techniques. Scientific research on post-mortem imaging shows this field is expanding rapidly.

Modular accessory rails transform a single cart into multiple specialized tools. Need specimen collection trays one day and imaging equipment mounts the next? These systems adapt instantly without requiring different carts for different procedures.

Smart Autopsy-Carts & Digital Integration

The digital revolution has finally reached the morgue, and it's making life significantly easier for pathology professionals. Built-in USB charging ports might sound like a small feature, but they solve a major headache. No more hunting for outlets or dealing with extension cords snaking across the floor.

Tablet mounts provide secure, adjustable positioning for digital documentation systems. These aren't flimsy aftermarket additions - they're engineered to withstand the rigorous cleaning protocols required in morgue environments. The mounts accommodate everything from iPads to rugged industrial tablets.

Electronic height presets store preferred positions for different procedures and operators. Dr. Smith's preferred examination height? Saved. The specific positioning for pediatric cases? Stored in memory. This technology improves efficiency while ensuring consistent positioning for standardized protocols.

Wireless connectivity enables seamless integration with laboratory information management systems. Real-time data transfer eliminates the transcription errors that plague manual documentation systems. The cart becomes part of your digital workflow rather than a separate piece of equipment.

Sustainable & Green Manufacturing

Environmental responsibility is becoming increasingly important in healthcare equipment manufacturing, and autopsy-cart production is no exception. Recycled stainless steel now makes up a significant portion of many carts without compromising quality or durability. Modern recycling processes actually produce steel that often exceeds virgin material specifications.

Energy-efficient welding techniques reduce manufacturing carbon footprint while producing superior welds. These advanced systems consume up to 40% less power than traditional welding methods while creating stronger, more consistent joints.

Low-VOC finishes eliminate harmful emissions during both manufacturing and daily use. These environmentally friendly coatings provide identical durability and appearance compared to traditional finishes, but without the environmental impact.

Modular design principles enable component replacement rather than complete unit disposal when parts wear out. This approach can extend equipment life by decades while dramatically reducing waste. When a caster wears out, you replace the caster - not the entire cart.

Frequently Asked Questions about Autopsy-Cart Selection

What weight capacity should my lab specify?

Choosing the right weight capacity for your autopsy-cart isn't just about numbers on a spec sheet - it's about ensuring your team can work safely and confidently every single day. Most pathology labs find that a standard 500-pound capacity handles their typical caseload with plenty of room to spare.

Think beyond just the weight of remains, though. During examinations, you're adding equipment, applying pressure for procedures, and sometimes repositioning bodies. All of these activities create "dynamic forces" - the cart experiences more stress than just the static weight sitting on top.

Bariatric models with 750-pound capacity become essential for facilities that regularly handle larger cases or simply want that extra peace of mind. The safety margin isn't just about preventing equipment failure - it's about protecting your staff and maintaining the dignity of every examination.

How do autopsy carts handle fluid drainage without spills?

This is where the engineering really shines in a quality autopsy-cart. The secret lies in those carefully calculated slopes built into the cart's surface. It might look like a simple slanted top, but there's real science behind getting that angle just right.

The slope channels every drop of fluid toward strategically placed drain holes - no pools, no stagnant areas where contamination could develop. It's like having a tiny, precision-engineered watershed right on your cart.

Those removable drain plugs on chains might seem like a small detail, but they're genius. You control exactly when and how drainage happens during procedures. The chain attachment saves you from searching for a lost plug in the middle of an examination.

When you position the cart over your autopsy sink, everything flows directly into your facility's waste management system. The recessed top design with raised edges acts like a containment system, keeping unexpected fluid volumes from escaping onto your floors.

What caster size and lock system are best for tiled morgue floors?

After years of helping labs select the right equipment, we've learned that 8-inch heavy-duty casters hit the sweet spot for morgue environments. They're large enough to handle the weight and roll smoothly over typical tile flooring, but not so big that maneuvering becomes difficult in tight spaces.

Smaller wheels create problems you might not expect. They put too much pressure on individual floor tiles, potentially causing damage over time. They also make the cart harder to push and steer, which leads to operator fatigue.

Total-lock brake systems are non-negotiable for examination work. You need both the wheel rotation and the swivel movement locked down solid when precision matters. Most professional carts use three total-lock casters plus one directional lock - this combination gives you rock-solid stability during procedures while still allowing precise positioning.

Polyurethane treads protect your expensive flooring while staying quiet during operation. These materials also resist all the chemicals and biological fluids they'll encounter, maintaining their performance even after years of use and countless cleaning cycles.

Conclusion

Selecting the right autopsy-cart significantly impacts your lab's safety, efficiency, and examination quality. The investment in professional-grade equipment pays dividends through improved workflow, reduced contamination risks, and improved operator safety.

Key selection criteria include construction quality, drainage system design, mobility features, and compatibility with existing equipment. The 14-16 gauge type 304 stainless steel construction, integrated fluid management, and heavy-duty caster systems represent non-negotiable requirements for professional applications.

Height adjustability, whether manual or powered, provides the flexibility needed for diverse examination requirements and operator ergonomics. Bariatric capabilities ensure your equipment can handle the full range of cases encountered in modern forensic pathology.

Integration with body trays, autopsy sinks, and other morgue equipment creates seamless workflows that improve both efficiency and safety. Proper equipment matching prevents compatibility issues and maximizes your investment value.

At American Mortuary Coolers, we understand the critical role that quality equipment plays in forensic pathology. Our experience serving pathology labs across Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, and Pennsylvania has shown us the importance of reliable, well-engineered autopsy carts.

We deliver custom solutions directly to facilities throughout the contiguous 48 states, ensuring you receive equipment that meets your specific requirements and space constraints. Our commitment to American manufacturing means you're investing in durable, locally-supported equipment that will serve your lab for years to come.

The next step involves assessing your current workflow, identifying integration requirements, and specifying the features that will best serve your lab's unique needs. Professional consultation ensures you select equipment that improves rather than complicates your examination procedures.

The Complete Guide to Mortuary Body Storage Solutions provides additional insights into creating comprehensive morgue equipment solutions that work together seamlessly.