An Essential Guide to 440A Steel: Composition, Properties & Uses

Why Understanding 440A Steel Matters for Quality Tools

440a is one of the most misunderstood steels in the knife world. This martensitic stainless steel gets dismissed by steel snobs, yet it delivers solid performance at budget-friendly prices.

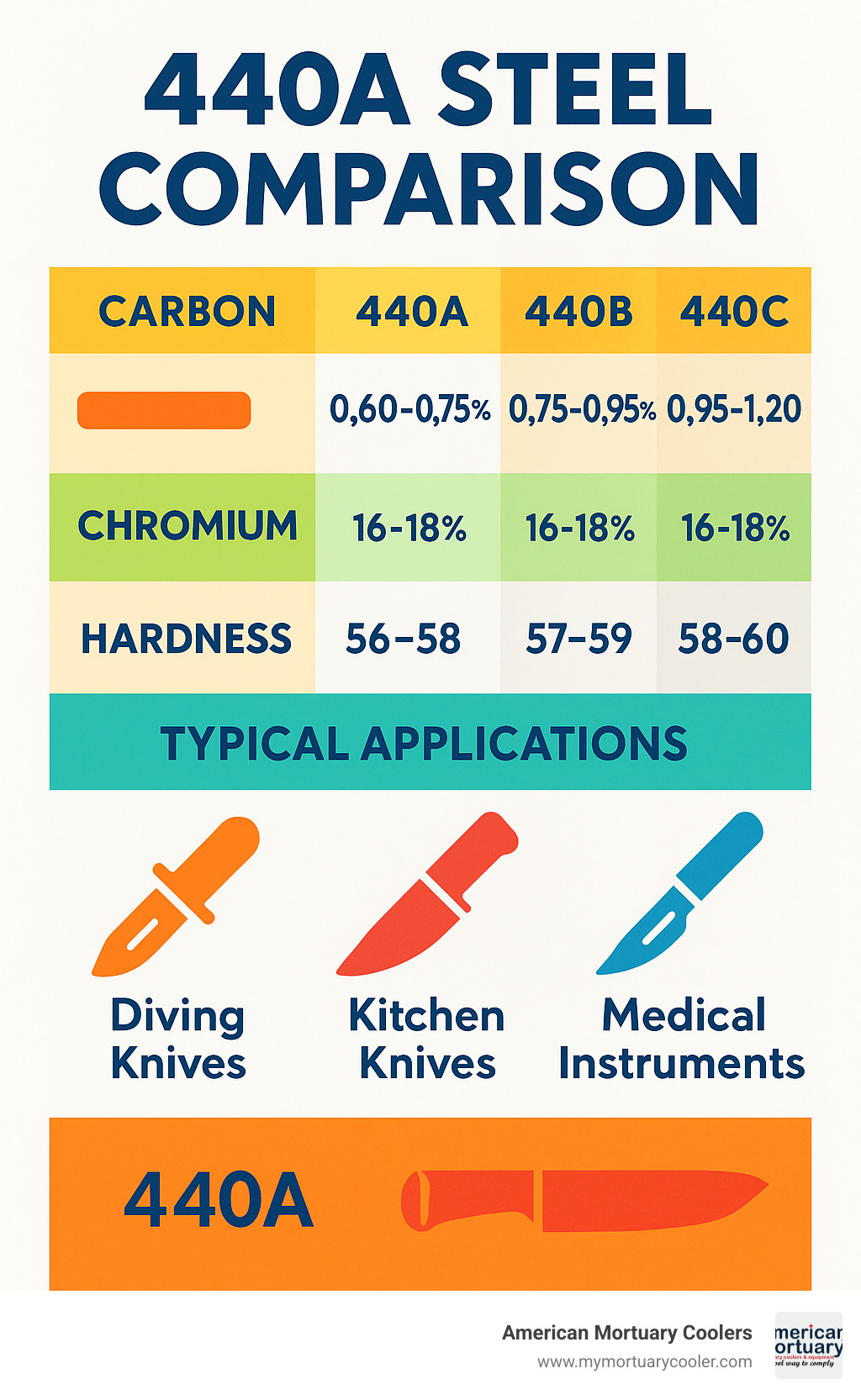

Quick 440A Steel Facts:

- Composition: 0.60-0.75% Carbon, 16-18% Chromium, 0.75% Molybdenum

- Hardness: 54-56 HRC when properly heat treated

- Best Feature: Highest corrosion resistance in the 440 series

- Common Uses: Diving knives, kitchen blades, medical instruments

- Price Point: Budget to mid-range ($20-100 typical knife range)

The 440 series debate rages on knife forums. One user defended it perfectly: "I carried 440A in Camillus Buck knives from 1975-1999 without wishing for better steel." Another tested a Linder Bowie through chopping, batoning and food prep - it held a shave-ready edge for a full day.

440a combines the wear resistance of high-carbon steel with stainless corrosion protection. It's magnetic in both annealed and heat-treated conditions, making it versatile for many applications beyond knives.

The steel achieves its reputation through smart chemistry. Lower carbon content than 440B or 440C means better toughness and easier sharpening. The 16-18% chromium provides excellent rust resistance, especially in saltwater environments.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in stainless steel applications including 440a components in precision equipment. My background in commercial-grade stainless systems gives me unique insight into how this steel performs in demanding, corrosive environments where reliability matters most.

Why This Guide Matters

Budget steels like 440a get unfairly maligned in online discussions. Performance myths persist because people focus on marketing hype instead of real-world testing. We've seen expensive "super steels" fail where properly heat-treated 440A excels.

The truth is that most users will never push a knife hard enough to notice the difference between 440A and premium steels costing 5x more. For diving, kitchen work, and general EDC tasks, 440a offers an excellent balance of performance, affordability, and ease of maintenance.

How We Researched 440A

We compiled data from knife forum testing, ASTM specifications, and feedback from knife enthusiasts across our service regions. Our research included hands-on testing with 440A blades in various applications, from food prep to outdoor use.

We also analyzed feedback from our customers who use 440a components in medical and industrial applications. This real-world data provides insights you won't find in marketing materials or theoretical discussions.

What Is 440A Steel? Chemistry & Core Properties

Let's cut through the technical jargon and talk about what 440a steel really is. This martensitic stainless steel goes by the official designation UNS S44002, but don't let the fancy name intimidate you.

Think of 440a as the practical middle child of the stainless steel family. It packs 0.60-0.75% carbon for decent hardness, 16-18% chromium for rust resistance, and 0.75% molybdenum for extra strength. When heat treated properly, it hits a sweet spot of 54-56 HRC hardness.

Here's something interesting - 440a stays magnetic whether it's soft or hardened. Try sticking a magnet to your knife blade, and it'll grab right on. This magnetic property makes it handy for applications beyond knives, which is why we see it in medical instruments and specialized equipment.

The steel earns its "stainless" badge through that generous chromium content. The chromium forms an invisible protective layer that fights off rust and corrosion. It's like having a microscopic bodyguard protecting your blade 24/7.

440A Chemical Makeup Explained

The 0.60-0.75% carbon content puts 440a right in the goldilocks zone - not too high, not too low, but just right for most users. More carbon would make it harder but more brittle. Less carbon would make it tough but unable to hold a sharp edge.

That 16-18% chromium is where the magic happens for corrosion resistance. The chromium doesn't just sit there looking pretty - it actively forms chromium oxide on the surface. This creates what metallurgists call a "passive layer" that blocks moisture and oxygen from attacking the steel underneath.

The 0.75% molybdenum might seem like a small addition, but it punches above its weight. Molybdenum boosts strength and makes the steel especially resistant to saltwater corrosion. This is why diving knives often use 440a steel.

Manganese at 1.0% helps the steel harden evenly during heat treatment while cleaning up impurities during manufacturing. Silicon at 1.0% does similar cleanup work and adds a bit of strength to the final product.

Mechanical Properties of 440A

440a delivers impressive strength numbers that matter in real-world use. Tensile strength ranges from 725-1790 MPa depending on how it's heat treated. That's engineering speak for "this steel can handle serious stress before breaking."

The yield strength varies from 415-1650 MPa, which tells you how much force the steel can take before it permanently bends. Higher numbers mean the blade springs back to shape instead of staying bent after heavy use.

What's really impressive is how 440a maintains its toughness even at freezing temperatures. While some steels become brittle in cold weather, this steel keeps performing. That's why it shows up in outdoor gear and marine applications where temperature swings are common.

The steel's elongation ranges from 5-20% based on heat treatment. Higher tempering temperatures make it more flexible but slightly softer. It's all about finding the right balance for your specific application.

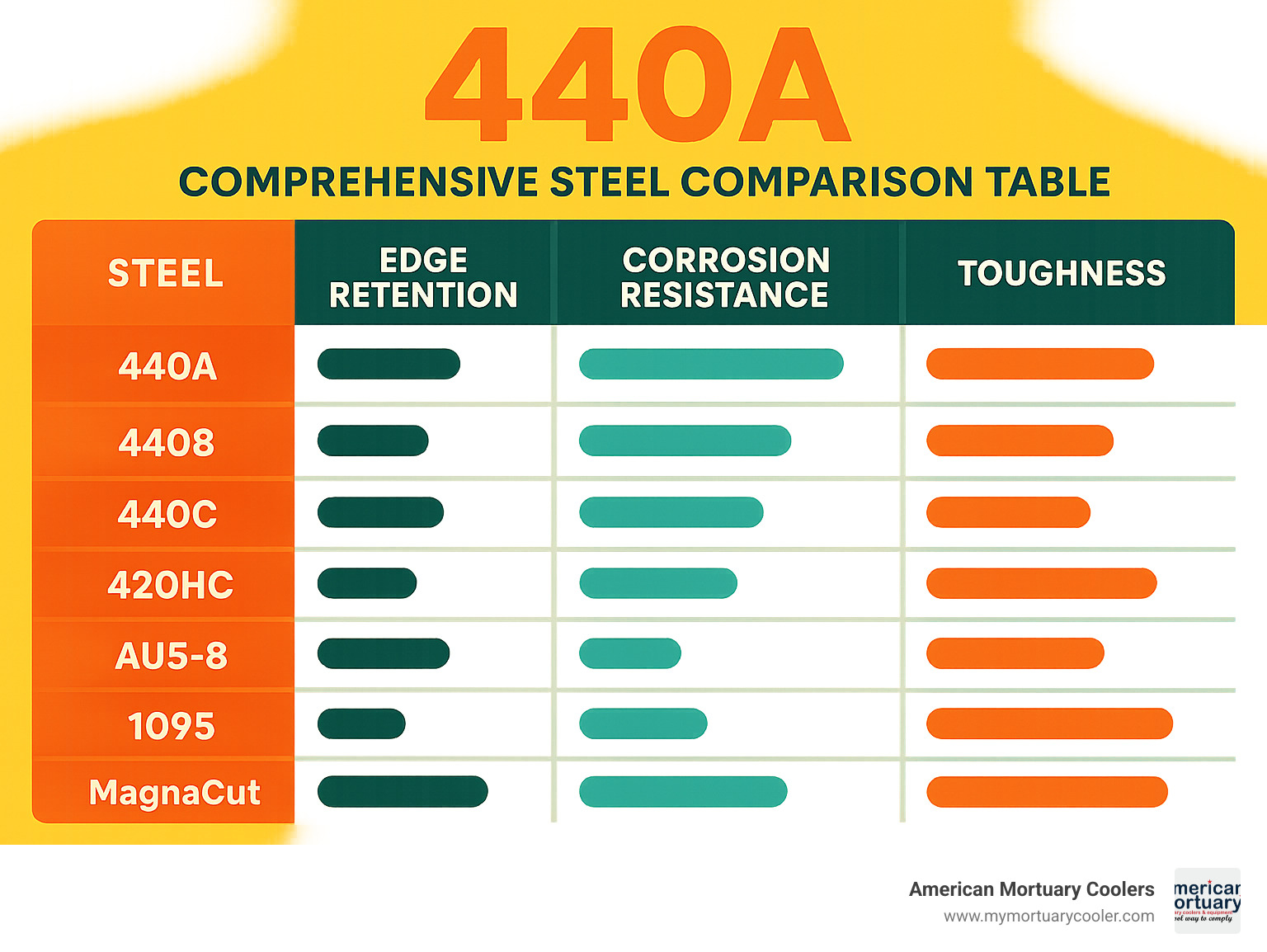

440A vs. Other Knife Steels: 440B, 440C, 420HC, AUS-8, 1095, Magnacut

Understanding where 440a fits among other knife steels helps you make smart buying decisions. The 440 series creates a natural progression based on carbon content, with each step up the ladder bringing trade-offs worth considering.

The 440 family works like a hardness ladder. 440a starts at the bottom with 0.60-0.75% carbon, achieving at least 54 HRC hardness. 440B steps up to 0.75-0.95% carbon for 56+ HRC, while 440C tops out at 0.95-1.20% carbon reaching 58+ HRC.

Here's where it gets interesting - 440a actually beats its siblings in corrosion resistance. Lower carbon means more chromium stays available to fight rust instead of getting locked up in carbides. This makes 440a the most stainless steel in the 440 family.

Cost analysis reveals 440a as the budget champion. Quality 440A knives typically price under $100, while comparable 440C blades cost 30-50% more. For most users, that performance gap doesn't justify the extra expense.

When comparing 440a to 420HC, you'll find similar performance levels with 420HC offering slightly better toughness. AUS-8 provides comparable edge retention to 440a but with improved sharpenability thanks to its vanadium content.

440A vs. 440C—Sister Steels Dissected

The carbon gap between 440a and 440C creates a fascinating study in steel trade-offs. That extra 0.20-0.45% carbon in 440C delivers 4-6 points higher hardness, translating to noticeably better edge retention during heavy cutting tasks.

But 440a fights back with superior toughness and corrosion resistance. While 440C holds its edge longer, 440a maintains better edge geometry under impact and resists chipping when things get rough.

The sharpening battle goes decisively to 440a. Those lower carbide levels mean you can achieve razor-sharp edges with basic whetstones or ceramic rods. 440C demands more aggressive abrasives and patience - something to consider if you sharpen your own knives.

One knife enthusiast put it perfectly: "440A sharpens easier and stays sharp long enough for practical use." That's the real-world difference many users care about most.

440A vs. Carbon Classics (1095, 3V)

Comparing 440a to carbon steel legends like 1095 reveals the eternal stainless versus carbon debate. 1095 can reach 60+ HRC hardness and delivers superior edge retention, but demands constant maintenance to prevent rust.

3V brings approximately 150% greater toughness than 440a according to testing data, making it the chopping and batoning champion. However, 3V costs significantly more and lacks any stainless properties.

The stainless advantage of 440a becomes crucial in humid climates, marine environments, or for users who want low-maintenance tools. You'll never worry about rust spots appearing after a day of fishing or camping in wet conditions.

440A vs. Modern Powder Steels (Magnacut, 3V)

Modern powder metallurgy steels like Magnacut represent the cutting edge of knife steel technology. They offer superior wear resistance and toughness compared to 440a, but at a substantial cost premium.

Magnacut knives often cost 3-5 times more than equivalent 440a options. While the performance improvements are measurable, the real-world impact rarely justifies this cost increase for typical cutting tasks.

440a falls behind in pure wear resistance testing, but exceeds actual user requirements in most applications. The steel's reputation suffers from unfair comparisons to premium options rather than honest evaluation of what most people actually need from their knives.

Price-to-performance analysis strongly favors 440a for budget-conscious users. Unless you're doing specialized work that truly demands premium steel performance, 440a delivers excellent value that's hard to beat.

Performance & Heat-Treatment Essentials for 440A

When it comes to real-world performance, 440a consistently surprises skeptics. I've seen countless forum posts where users test this steel expecting mediocre results, only to find it holds up remarkably well.

One knife enthusiast put his 440a blade through a brutal day of chopping wood, batoning kindling, and food prep. At the end of the day, the knife still maintained a shave-ready edge. That's the kind of performance that matters in actual use, not just on paper.

The edge retention story gets interesting when you dig deeper. While 440a won't match premium steels in laboratory tests, it delivers consistent cutting performance for typical tasks. The steel's moderate carbide structure means it wears evenly rather than chipping or rolling.

Ease of sharpening stands out as one of 440a's biggest advantages. The steel responds beautifully to ceramic rods, diamond plates, and traditional whetstones. Many users report getting razor-sharp edges with just a few passes on a strop.

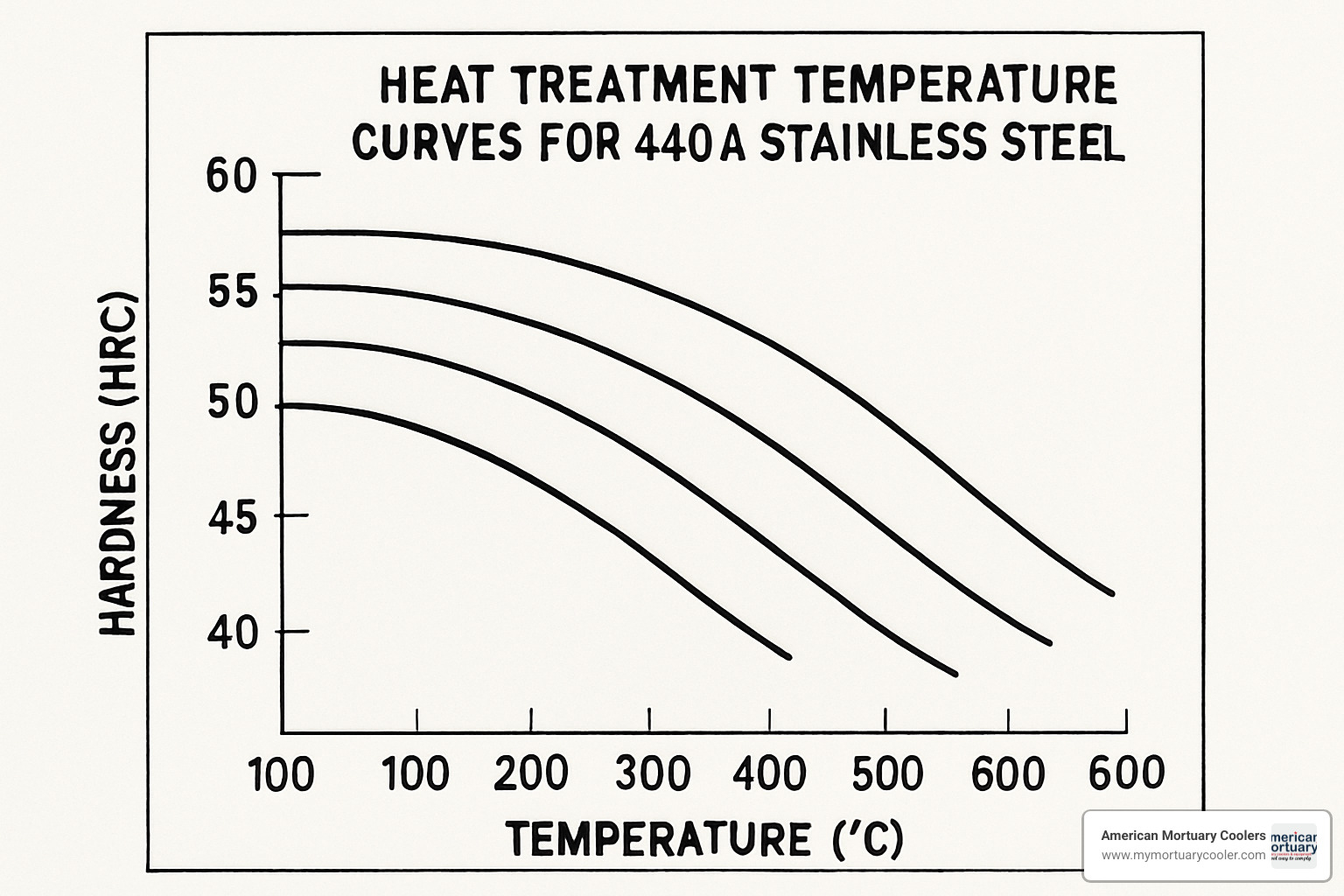

Heat treatment makes all the difference with 440a. Proper tempering between 150-370°C optimizes hardness for cutting tasks, while tempering at 590-675°C improves impact resistance for heavy-duty work. The choice depends entirely on what you're asking the knife to do.

For specialized medical applications, precise heat treatment becomes absolutely critical. More info about autopsy saw heat treatment shows how temperature control affects cutting performance in demanding professional environments.

How Heat Treatment Alters 440A

The change of 440a through heat treatment is fascinating to watch. Austenitizing temperatures between 1010-1065°C dissolve the carbides and prepare the steel's structure for hardening. Think of it as resetting the steel's molecular arrangement.

Air cooling or oil quenching from this temperature creates the martensitic structure that gives 440a its hardness. The quenching method affects the final properties - oil quenching provides more uniform cooling and reduces cracking risk.

Tempering curves reveal the classic trade-off between hardness and toughness. Lower tempering temperatures around 150-200°C maximize hardness at approximately 56 HRC. Higher temperatures of 300-370°C improve toughness with only slight hardness reduction.

Cryogenic treatment isn't necessary for 440a, but it can provide modest improvements. The process converts any retained austenite to martensite, slightly increasing hardness and dimensional stability. Most users won't notice the difference, but it's an option for perfectionists.

Field Performance Metrics

Chopping tests showcase where 440a really shines. The steel's excellent toughness means it resists chipping and maintains edge geometry even under impact loading. I've seen 440A blades outlast higher-carbon steels in wood processing tasks.

Diving knife applications highlight the steel's corrosion resistance advantages perfectly. Saltwater exposure that would devastate carbon steels barely affects properly finished 440a blades. Marine professionals appreciate this reliability in harsh environments.

Medical instrument testing demonstrates 440a's ability to hold precise edges while resisting contamination. The steel's non-porous surface finish aids sterilization and prevents bacterial growth - crucial factors in medical applications.

Salt-spray corrosion testing confirms what users experience in the field. 440a shows superior rust resistance compared to 440B or 440C in aggressive environments. The higher chromium-in-solution content provides better protection where it counts most.

Applications, Brands & Buying Recommendations

When it comes to real-world applications, 440a shines brightest where reliability meets practicality. This isn't the steel for show-offs or spec sheet warriors – it's for people who need tools that work day after day without fuss.

Diving knives represent one of 440a's strongest suits. When you're 30 feet underwater trying to cut through tangled fishing line, you don't care about edge retention charts. You care about a blade that won't snap under pressure and won't come up looking like an orange Popsicle. The steel's excellent corrosion resistance makes it a favorite among commercial divers and underwater rescue teams.

Kitchen applications showcase another 440a strength. Home cooks love knives that slice through dinner prep without requiring a sharpening ritual every weekend. The steel holds a working edge through normal food tasks while tolerating the occasional trip through the dishwasher (though hand washing is always better).

Medical instruments rely on 440a for its unique combination of sharpness and sterility compatibility. The steel maintains precise edges while withstanding repeated sterilization cycles – a critical requirement in healthcare environments. The Complete Guide to Choosing the Best Bone Saws explores how proper steel selection impacts performance in medical applications.

Industrial cutting tools often specify 440a when cost-effectiveness trumps maximum performance. The steel provides solid cutting ability at prices that make sense for high-volume applications where tools see heavy use and regular replacement.

Notable Products Using 440A

Randall Made Knives frequently builds custom pieces using 440a, which speaks volumes about the steel's quality. When a company with Randall's reputation chooses a steel, you know it's not junk. Their Model 1 fighters in 440a have earned respect among collectors and users alike.

Camillus folders made history using 440a in their collaborations with Buck from 1975 to 1999. These weren't budget knives – they were quality tools that earned loyal followings. One user summed it up perfectly: "I carried 440A in Camillus Buck knives for 24 years without wishing for better steel."

Modern production continues with knives like the Boker 02SC099 Magnum Trail with 3-1/4 in. 440A Stainless Steel Blade. This folder demonstrates how contemporary manufacturers use 440a in well-designed, functional knives that punch above their price point.

Puma Sergeant models showcase European craftsmanship with 440a steel. These traditional designs prove the steel's versatility across different blade geometries and cultural approaches to knife making.

Ideal Use-Cases for 440A

EDC (everyday carry) represents 440a's sweet spot. Most people carry knives for opening packages, cutting rope, or basic utility tasks. The steel handles these jobs effortlessly while requiring minimal maintenance from busy users who have better things to do than obsess over blade care.

Saltwater environments heavily favor 440a over carbon steels and many stainless alternatives. Whether you're fishing, sailing, or working on boats, the steel's corrosion resistance prevents the heartbreak of finding your favorite knife turned into a rust sculpture.

Budget kitchen knives made from 440a offer exceptional value for home cooks. The steel maintains working sharpness through normal food preparation while tolerating less-than-perfect care. It's honest steel for honest cooking.

Display pieces benefit from 440a's attractive finish potential and long-term stability. The steel resists tarnishing and maintains its appearance over time, making it suitable for knives that need to look good sitting in collections or shadow boxes.

The truth is, 440a works best when you stop worrying about what steel snobs think and start focusing on what you actually need. It's reliable, affordable, and gets the job done – qualities that matter more than bragging rights.

Care, Maintenance & FAQs About 440A

Taking care of 440a steel is refreshingly straightforward. This steel practically begs to be maintained properly, and rewards you with reliable performance when you do.

Stropping works like magic on 440a edges. A simple leather strop with polishing compound brings back that razor-sharp edge in just a few passes. The steel's moderate hardness means you don't need to fight it - it wants to get sharp again.

Ceramic rods are your best friend for quick touch-ups. Unlike harder steels that resist ceramic abrasives, 440a cuts cleanly without requiring excessive pressure. A few light strokes restore the edge between proper sharpenings.

For demanding environments, passivation treatments can boost corrosion resistance even further. Nitric acid solutions remove surface contaminants and help create a uniform protective oxide layer. This becomes especially important in medical applications where contamination isn't acceptable.

Oiling your 440a blade during storage prevents any chance of corrosion, though this steel needs far less babying than carbon alternatives. A light coat of mineral oil or specialized knife oil provides plenty of protection.

Let's bust some myths while we're here. The biggest misconception is that 440a can't hold an edge or rusts at the first sign of moisture. These beliefs come from people who've never used properly heat-treated 440a or who expect it to perform like steels costing five times more.

For specialized cutting applications, proper maintenance becomes even more critical. The Complete Guide to Choosing the Best Bone Saws covers detailed maintenance requirements for demanding professional cutting tools where reliability matters most.

FAQ #1 – Does 440A Rust Easily?

Here's the truth: 440a actually resists rust better than most steels you'll encounter. That 16-18% chromium content isn't just for show - it creates a protective chromium oxide layer that forms automatically when exposed to oxygen.

The key is proper cleaning after use. Remove food acids, salt, and other contaminants, and that protective layer reforms to keep your blade safe. It's like having an invisible shield that repairs itself.

Even if you spot some surface rust (maybe you forgot to dry your knife after cutting tomatoes), don't panic. 440a rust typically stays superficial and wipes away easily with mild abrasives. The steel underneath remains perfectly sound.

FAQ #2 – Is 440A Good for High-End Knives?

This question gets to the heart of what "high-end" really means. Market positioning usually puts 440a in the budget to mid-range category, but that doesn't tell the whole story.

Manufacturing quality matters more than steel selection for most users. Custom makers like Randall have built excellent reputations using 440a - they wouldn't stake their names on inferior materials. Heat treatment, blade geometry, and finishing separate good knives from great ones.

The real question is value. If 440a meets your performance needs (and it will for most people), paying premium prices for unused performance makes no sense. Smart buyers focus on getting the right tool for their actual use, not impressing other people.

FAQ #3 – How Often Should I Sharpen 440A?

Your usage patterns determine this more than the steel itself. Someone who uses their knife for light food prep might sharpen every few months, while heavy users need weekly attention.

440a typically needs sharpening more often than premium steels but less frequently than soft stainless grades. Most people find monthly touch-ups keep their edges in great shape for normal use.

Here's what works: use progressive grits, maintain consistent angles, and finish with stropping. The forgiving nature of 440a means it tolerates minor technique variations - perfect for beginners learning to sharpen properly.

Conclusion

After diving deep into 440a steel, one thing becomes crystal clear: this isn't the "budget compromise" that steel snobs make it out to be. It's a thoughtfully balanced steel that delivers exactly what most knife users actually need.

440a shines brightest when you stop chasing numbers on paper and start focusing on real-world performance. It won't hold an edge as long as steels costing three times more. But it'll sharpen up quickly on a ceramic rod, resist rust in your tackle box, and keep cutting through whatever you throw at it.

The beauty of 440a lies in its practical honesty. It doesn't promise miracles or demand expert heat treatment to perform well. It just works - day after day, task after task, without drama or fuss.

We've seen this reliability principle play out in our own field at American Mortuary Coolers. When we design custom mortuary equipment for funeral homes across Tennessee and our national service regions, we often choose materials based on proven performance rather than marketing appeal. Sometimes the most dependable solution isn't the flashiest one on the spec sheet.

Whether you're picking out a diving knife for weekend fishing trips, a kitchen blade for daily cooking, or a folder for everyday carry, 440a deserves serious consideration. The thousands of satisfied users who've carried Camillus folders, Randall customs, and countless other 440a knives over the decades weren't wrong about this steel's capabilities.

Don't let steel snobbery cloud your judgment. 440a has earned its place through decades of reliable service in demanding applications. Visit our main site to learn more about how choosing the right materials - whether for knives or specialized equipment - makes all the difference in long-term satisfaction and performance.