An Essential Guide to Choosing the Right Manual Stretcher

Why Manual Stretchers Remain Essential in Modern Healthcare

A manual stretcher is a patient transport device operated entirely by human power, without hydraulic, electric, or pneumatic assistance. These stretchers are controlled through manual levers, cranks, and gas-spring mechanisms for height and backrest adjustments.

Key Manual Stretcher Features:

- Weight Capacity: 250-700 lbs (135-317 kg)

- Height Range: 13.8-42.2 inches adjustable

- Backrest Angle: 0-70° articulation

- Operation: 1-2 operators required

- Applications: Emergency rooms, ambulances, patient transport, mortuary services

- Materials: Aluminum alloy frame, ABS platform, 6-inch diameter wheels

Manual stretchers serve critical roles across healthcare settings, from emergency departments to funeral homes. Unlike powered alternatives, they offer reliability without batteries, lower maintenance costs, and simplified operation during high-stress situations. Research shows that manual stretchers account for 427 models from 146 companies, far exceeding hydraulic (29) and electric (5) variants in the market.

These devices have evolved from basic improvised litters using "blankets, web belts, pagri, ground sheets and bamboo pieces" to sophisticated aluminum-frame systems with gas-spring backrests and central brake systems. Modern manual stretchers balance patient comfort with operational efficiency, featuring everything from shock-absorbing wheels to radiolucent surfaces for imaging compatibility.

As Mortuary Cooler, I've spent years helping funeral directors select durable, American-made manual stretcher solutions that meet strict space and budget requirements. My experience with mortuary equipment has shown that the right manual stretcher choice significantly impacts both operational efficiency and service quality.

Easy manual stretcher word list:

What Is a Manual Stretcher?

Picture this: you're in the middle of a power outage, and you need to move a patient safely. A manual stretcher becomes your reliable partner - no batteries required, no hydraulics to fail, just dependable human-powered operation when you need it most.

A manual stretcher is simply a patient transport device that runs entirely on human power. Every adjustment - from height changes to backrest positioning - happens through hand-powered controls like levers, cranks, and gas-spring mechanisms. There's no hydraulics humming in the background and no motor that might quit at the worst possible moment.

You'll find these workhorses everywhere in healthcare. Emergency rooms rely on them for quick patient transfers. Ambulances count on their reliability during transport. For intra-hospital transport, they offer the perfect balance of functionality and simplicity. Even funeral homes depend on them for dignified, quiet operation.

Manual Stretcher Basics

The beauty of a manual stretcher lies in its straightforward design. The frame serves as the foundation, built to handle everything from routine transports to emergency situations using pure human power.

Most manual stretchers work in one of two ways. You've got your two-bearer models that require lifting - think emergency field situations where you need to carry someone over rough terrain. Then there are the wheeled versions designed for one-operator push systems, perfect for smooth hospital floors and corridors.

What makes these stretchers so appealing? They're refreshingly simple. Fewer moving parts mean fewer things can break down. Your staff can master the controls quickly without wrestling with complicated powered systems or worrying about battery life.

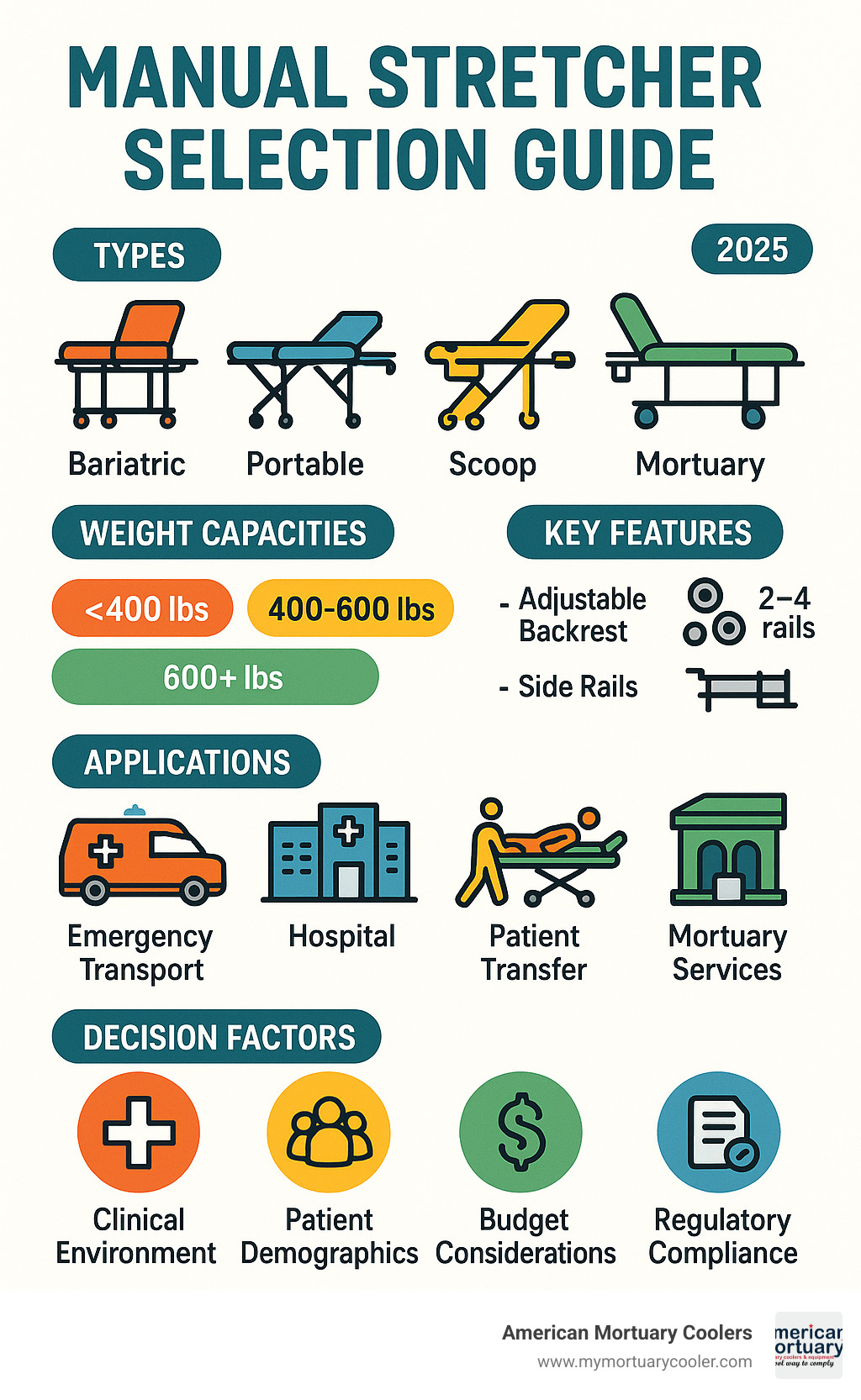

Manual Stretcher Types

The world of manual stretchers is more diverse than you might expect. Each type tackles specific challenges that healthcare providers face daily.

Transport trolleys are the bread and butter of hospital systems. These wheeled champions feature adjustable backrests, protective side rails, and central brake systems that keep patients secure during movement.

Scoop stretchers solve a tricky problem with neat engineering. Their split-frame design lets emergency responders literally scoop up patients without dangerous rolling or lifting - a game-changer for suspected spinal injuries where every movement matters.

When standard stretchers aren't enough, bariatric models step up with reinforced frames and wider platforms. These heavy-duty units safely support patients up to 700 pounds, complete with specialized wheel configurations that handle the extra weight.

Stair stretchers tackle one of healthcare's most challenging transport scenarios. With flexible uplift rods and compact, foldable designs, they steer tight staircases and cramped spaces that would stop regular stretchers cold.

For funeral homes, mortuary stretchers offer specialized features like smooth, easy-to-clean surfaces and accessories designed for dignified transport. Veterinary models adapt the same principles for animal care, often featuring radiolucent materials for imaging procedures.

Even field improvised stretchers deserve mention. When manufactured equipment isn't available, these can be constructed from blankets, poles, and straps - a capability that has saved countless lives in military and disaster response situations.

Key Components & Technical Specifications

When you're choosing a manual stretcher, understanding the technical details makes all the difference between equipment that works and equipment that works brilliantly for years to come. Let me walk you through what really matters in modern manual stretcher construction.

The foundation starts with materials that can handle the job. Most quality manual stretchers use aluminum alloy frames because they give you the best of both worlds - incredible strength without the back-breaking weight. We're talking about stretchers that weigh just 40-89 pounds but can safely carry patients up to 700 pounds.

Stainless steel components show up in the areas that need extra durability, especially in environments where moisture and frequent cleaning are facts of life. The patient platform typically uses ABS plastic - it's tough, easy to clean, and comfortable for patients during transport.

The adjustable backrest on most manual stretchers moves from completely flat (0°) up to 70°, with some models reaching 85°. This range lets you position patients comfortably whether they're conscious and prefer sitting up or need to lie flat for medical reasons.

Height adjustment typically ranges from about 14 inches up to 42 inches. This flexibility means your stretcher works with different ambulance heights and makes transfers to hospital beds much easier on everyone's back.

The mobility features deserve special attention. Fifth wheel steering systems give you a retractable wheel that pops out from the center of the stretcher, letting you spin it in place or steer tight corners with ease. Combined with standard 6-inch casters, you get smooth rolling over different floor surfaces.

Safety features like central brake systems mean one pedal locks all wheels at once. Side rails fold down when you need patient access but provide security during transport.

Frame & Platform Details

The frame construction tells you everything about how long your manual stretcher will last. Welded joints beat bolted connections every time - they're stronger and won't work loose over years of use.

X-frame designs have become popular because they distribute weight beautifully while keeping the overall stretcher weight manageable. Take the Performance-PRO XT as an example - it uses an all-aluminum X-frame that supports 700 pounds while the whole stretcher weighs just 89 pounds.

Radiolucent boards are a game-changer in healthcare settings. They let X-rays pass through, so patients don't need to be moved off the stretcher for imaging. This saves time and reduces the risk of injury during transfers.

Corrosion resistance matters more than you might think. Healthcare environments are tough on equipment - constant cleaning with harsh chemicals, moisture, and daily wear. Quality stretchers use protective coatings and smart material choices that stand up to this punishment year after year.

Height & Backrest Adjustment

The adjustment mechanisms separate good stretchers from great ones. Manual cranks use gear reduction to make height changes easy, even with a patient on board. You're not fighting the weight - the mechanical advantage does the work.

Gas springs have revolutionized backrest adjustment. The Amico Emergency Care Stretcher uses these gas-powered mechanisms to give you smooth, controlled positioning without any power source. They're reliable, quiet, and surprisingly precise.

Lever systems offer the quickest operation, especially foot-operated levers that keep your hands free during transfers. Some stretchers include shock positioning capabilities (usually +15° beyond normal range) and Trendelenburg positioning for head-down positioning when medically necessary.

Wheels, Brakes & Rails

The 150mm casters (that's about 6 inches) have become the sweet spot for manual stretchers. They're large enough to roll smoothly over door thresholds and small debris but not so big they make the stretcher unwieldy.

Central brake pedals are often color-coded to help operators find them quickly under stress. Corner bumpers protect both your stretcher and everything else in tight hallways.

Fold-down rails give you the best of both worlds - patient security when needed and full access for procedures. Some models feature bumper-protected siderails that keep patient hands safe during transport.

Accessories & Options

The accessories can transform a basic manual stretcher into exactly what your facility needs. Oxygen holders mount directly to the stretcher frame, keeping portable tanks secure during transport. Most stretchers come with two patient straps as standard equipment.

XPS extra-wide rails can increase the effective surface area by 38% - a real blessing for larger patients. Head extensions accommodate taller patients, while pediatric inserts safely adapt adult stretchers for children.

For imaging applications, radiolucent imaging pads replace standard mattresses when you need X-ray compatibility. These small details make the difference between equipment that works and equipment that works perfectly for your specific needs.

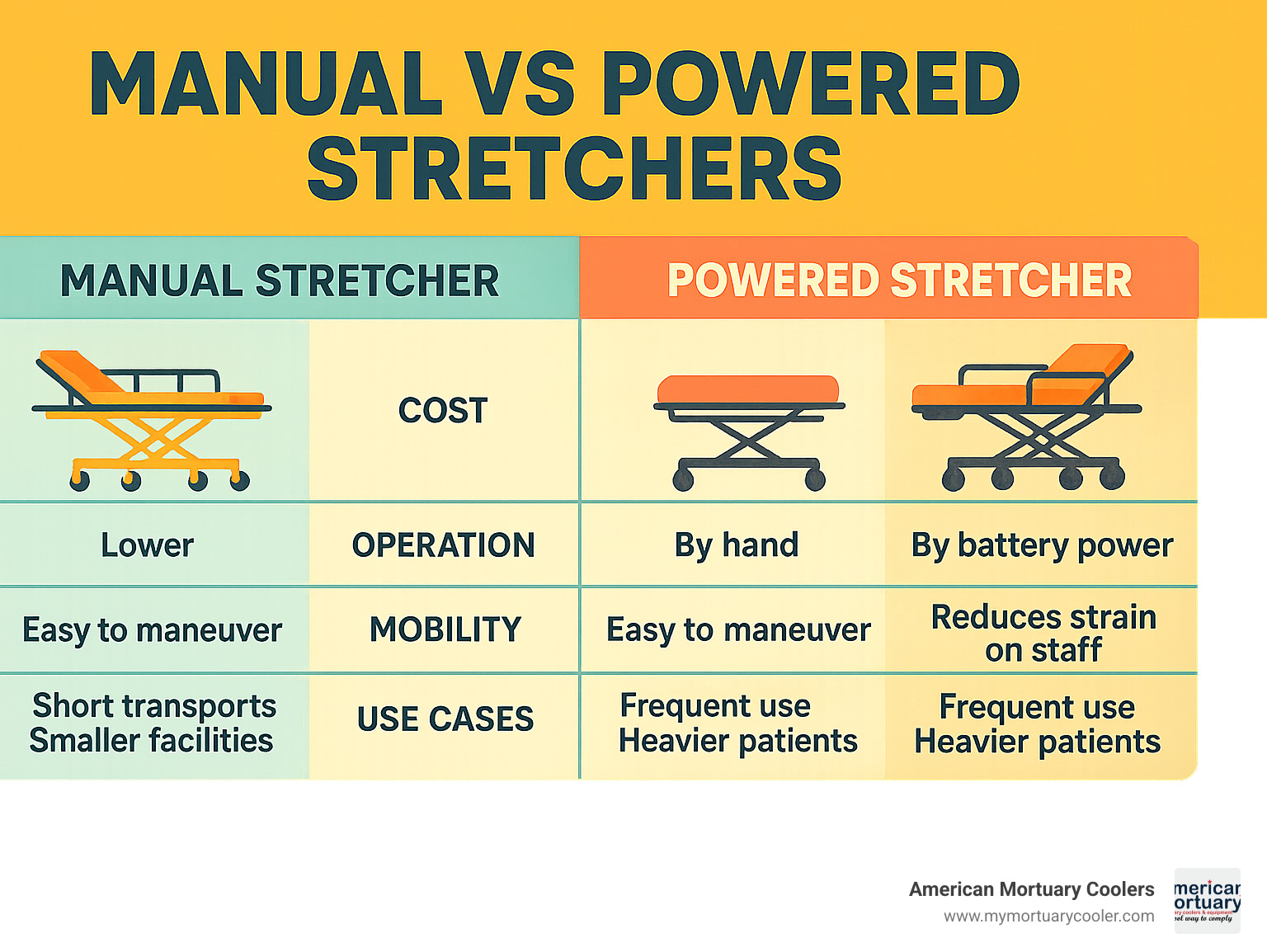

Manual vs Powered Stretchers: Pros, Cons & Use Cases

Choosing between a manual and a powered stretcher comes down to four essentials: weight, cost, maintenance, and operator effort. Manual models usually weigh 40-89 lb, need just routine mechanical upkeep, and cost $900–$5,500. Powered units add motors and batteries that reduce lifting strain but raise purchase price, weight, and long-term service costs.

In busy emergency departments, powered assistance can speed frequent height changes. Yet field medics, funeral homes, and facilities with tight stairwells often prefer the lighter, go-anywhere reliability of manual systems—especially where power outlets (or spare batteries) are scarce.

Advantages of Manual Stretchers

- Lightweight & maneuverable: Easier to load into vehicles and steer through narrow corridors.

- No battery dependence: Always ready, even during outages or prolonged calls.

- Lower total cost of ownership: Fewer electronic parts mean cheaper repairs and less downtime.

- Water-washable construction: Many units tolerate pressure washing for rapid infection-control turnaround.

Limitations & When to Choose Powered

- Operator strain with heavy patients: Cranking a 600-lb load multiple times per shift is hard on staff.

- High-frequency elevation changes: Powered lifts save time and reduce injury risk in large hospitals.

- Very long transports: Motorized height adjustment can improve ergonomics on extended intra-facility moves.

When budgets are tight, power is unreliable, or portability is critical, a well-built manual stretcher remains the safest, most economical choice. Reserve powered models for environments where staff fatigue or bariatric caseloads consistently outweigh those benefits.

How to Choose the Right Manual Stretcher

Choosing the right manual stretcher doesn't have to feel overwhelming. Think of it like finding the perfect tool for your specific job - you need to match the equipment to your exact needs, not the other way around.

I've helped countless facilities steer this decision over the years, and the key is breaking it down into manageable pieces. Start with your clinical area, consider your patient population, and then factor in the practical stuff like doorways and budgets.

The comprehensive stretcher trolley guide offers additional technical insights when you're dealing with complex requirements.

Your clinical area sets the foundation for everything else. Emergency departments need stretchers that can handle chaos - easy to clean, quick to deploy, and reliable when seconds count. Surgical suites, on the other hand, might need radiolucent surfaces for imaging or precise positioning capabilities that basic models can't provide.

Patient demographics tell you a lot about what you actually need. If you're regularly serving bariatric patients, those reinforced frames and wider platforms aren't luxury features - they're necessities. Pediatric facilities benefit from adjustable sizing options that can safely accommodate smaller patients.

Don't overlook the boring but crucial stuff like door widths and elevator dimensions. I've seen facilities order perfect stretchers that couldn't fit through their own doorways. Most standard hospital doors work fine, but older buildings or specialized areas might need compact designs.

Infection control requirements influence everything from surface materials to cleaning protocols. High-turnover areas really benefit from smooth surfaces and materials that can handle aggressive disinfection without breaking down.

Budget constraints typically fall between $900 for basic models and over $5,000 for specialized units. Remember to think about total cost of ownership - that includes maintenance, training, and any accessories you'll need down the road.

Warranty coverage varies dramatically, from one year to five years depending on the manufacturer. Longer warranties often signal higher build quality and give you peace of mind about your investment.

Lead times can stretch several weeks for custom configurations, so plan accordingly. Nothing's worse than needing equipment yesterday and finding out it won't arrive for two months.

Clinical & Environmental Factors

Emergency room applications demand stretchers that can handle anything. Central brake systems and color-coded controls become lifesavers when your staff is working under pressure and can't afford to fumble with complicated mechanisms.

Operating room compatibility gets more technical. You might need radiolucent surfaces for imaging, precise positioning capabilities, or MRI compatibility that eliminates any ferromagnetic materials. These aren't just nice-to-have features - they're safety requirements.

Outdoor rescue scenarios flip the script entirely. Here you need lightweight, portable designs that work reliably in terrible conditions. Weather resistance and dead-simple operation become your top priorities.

Bariatric programs require serious engineering. We're talking reinforced frames, wider platforms, and improved stability features. Weight capacities of 700+ pounds aren't just numbers on a spec sheet - they're critical safety requirements.

Safety & Ergonomics Considerations

Fall prevention features protect your most vulnerable patients. Appropriate side rail heights, secure locking mechanisms, and stable base designs aren't optional - they're essential. Research shows that bumper-protected siderails help prevent hand injuries during transport.

Siderail height needs to balance patient security with staff access. Adjustable or removable rails give you flexibility for different situations without compromising safety.

Color-coded pedals and controls reduce mistakes when everyone's stressed. Visual cues help ensure proper brake engagement and height adjustment, even when your staff is having the worst day ever.

Caregiver biomechanics matter more than most people realize. Appropriate handle heights, smooth rolling characteristics, and reasonable force requirements for manual adjustments can prevent injuries and reduce fatigue.

The Medical Stretcher vs Mortuary Stretcher guide helps clarify the differences between medical and mortuary applications, ensuring you get equipment designed for your specific needs.

Budget, Service & Compliance

Price bands typically range from $900 for basic models to $5,500 for specialized configurations. Think beyond the sticker price - consider maintenance costs, training requirements, and accessories you'll need over the equipment's lifetime.

CE marking indicates European Conformity for medical devices, ensuring the equipment meets safety and performance standards. FDA approval may be required for certain clinical applications, particularly in acute care settings.

ISO 9001 certification demonstrates that the manufacturer has solid quality management systems in place. It's a good indicator that you're dealing with a company that takes consistency seriously.

Warranty periods range from one to five years, with some manufacturers offering extended coverage on frames and welds. The YA-PS05, for example, provides three years on frame and welds with one year on parts - that's the kind of confidence you want to see.

Parts availability affects how long you can keep your equipment running. Established manufacturers typically maintain parts inventory even for discontinued models, while newer companies might leave you stranded when something breaks.

Maintenance, Cleaning & Regulatory Compliance

Proper maintenance and cleaning protocols ensure reliable operation and regulatory compliance throughout the stretcher's service life. Our experience with mortuary equipment has shown that consistent maintenance practices significantly extend equipment longevity.

Daily wipe-down procedures should use neutral detergents compatible with stretcher materials. Avoid harsh chemicals that could damage protective coatings or compromise structural integrity.

Power-wash ratings vary by manufacturer and model. Many manual stretchers tolerate high-pressure cleaning, but verify specifications before implementing aggressive cleaning protocols.

Caster lubrication requires regular attention, particularly in high-use environments. Proper lubrication ensures smooth rolling and extends bearing life.

Annual load testing verifies continued safe operation under maximum rated capacity. Document testing results for regulatory compliance and risk management purposes.

Operator training should cover proper lifting techniques, brake engagement, and safety protocols. The detailed military litter manual provides comprehensive training guidance applicable to civilian applications.

CE marking requirements mandate specific documentation and testing protocols for European markets.

Manual Stretcher Inspection Checklist

Brake testing should verify proper engagement and release of all wheel locks. Test under both loaded and unloaded conditions to ensure reliable operation.

Rail locks require inspection for proper engagement and security. Verify that locking mechanisms hold firmly under typical patient movement.

Mattress integrity affects patient comfort and infection control. Replace mattresses showing wear, tears, or compression loss.

Strap expiry dates must be monitored for patient restraint systems. Replace expired straps regardless of apparent condition.

Frame welds should be inspected for cracks, distortion, or other signs of fatigue. Pay particular attention to high-stress areas around pivot points and load-bearing joints.

Certification & Documentation

IFU availability (Instructions for Use) ensures proper operation and maintenance procedures are accessible to all operators.

Service logs document maintenance activities, repairs, and inspections for regulatory compliance and warranty purposes.

Risk assessment protocols help identify potential hazards and implement appropriate mitigation strategies.

Traceability requirements may mandate serial number tracking and maintenance history documentation for regulatory compliance.

Frequently Asked Questions about Manual Stretchers

When you're considering a manual stretcher purchase, certain questions come up repeatedly. Having helped countless funeral directors and healthcare facilities make these decisions, I've found these three questions capture the most important concerns.

How much weight can a manual stretcher safely carry?

The weight capacity of manual stretchers varies dramatically based on their intended use and construction quality. You'll find basic models that safely handle 250-350 pounds, while heavy-duty bariatric versions can support up to 700 pounds or more.

Here's what's impressive: the Performance-PRO XT manages to support a full 700 pounds while the stretcher itself weighs only 89 pounds. That's exceptional engineering using aluminum X-frame construction that maximizes strength while minimizing weight.

The secret lies in the materials and design. Aluminum X-frame designs typically offer the best strength-to-weight ratios, while manufacturers add reinforced structural elements when higher capacities are needed. Stainless steel components and welded joints contribute significantly to overall load-bearing capability.

Always build in a safety margin when selecting equipment. Your total load includes the patient's weight plus any medical equipment, oxygen tanks, or accessories. Stay comfortably within the manufacturer's rated limits - it's not worth the risk to push boundaries.

What certifications should a quality manual stretcher meet?

Quality manual stretchers should carry FDA approval for medical device applications, which ensures they meet rigorous safety and performance standards for healthcare use. You'll also want to see CE marking if you're dealing with European compliance requirements.

ISO 9001 certification tells you the manufacturer maintains consistent quality management systems throughout their production process. This certification often correlates with better build quality and more reliable customer service.

Different applications may require additional certifications. Military specifications demand extra testing protocols, while mortuary applications might have different requirements than acute care models. Fire safety ratings and environmental compliance markers can also be important depending on your facility's needs.

The key is matching certifications to your intended use. Don't assume all stretchers meet the same standards - ask manufacturers for documentation that proves compliance with your specific requirements.

How do manual stretchers improve patient comfort without motors?

This question always surprises people who assume comfort requires powered features. Manual stretchers actually offer several comfort advantages through thoughtful mechanical design.

Gas-spring backrest systems provide incredibly smooth positioning without any motors or hydraulics. These systems offer controlled, gradual adjustment that's often more comfortable than abrupt powered movements. The gas springs maintain consistent support throughout the adjustment range.

Quality mattresses and padding make a huge difference in patient comfort. Proper weight distribution reduces pressure points and provides better support during transport. Many facilities underestimate how much the right mattress contributes to overall patient experience.

Shock-absorbing wheel systems minimize the bumps and vibrations that make transport uncomfortable. The Hillrom Transport Stretcher's Steering Plus system, for example, actively absorbs impacts from door thresholds and floor irregularities for much gentler rides.

Proper sizing matters enormously for comfort. Optional accessories like XPS extra-wide rails can increase the surface area by up to 38% for larger patients, providing better support and reducing the confined feeling that narrow stretchers can create.

The reality is that comfort comes more from thoughtful design than from powered features. A well-designed manual stretcher with quality components often provides better patient comfort than a poorly designed powered unit.

Conclusion

Manual stretchers thrive on the fundamentals: simplicity, durability, and dependable performance without a plug or battery in sight. For budget-conscious hospitals, emergency crews, and funeral homes alike, they deliver professional capability at a fraction of the cost and upkeep of powered alternatives.

At American Mortuary Coolers, we see every day how the right transport equipment keeps operations smooth during life’s most critical—or most delicate—moments. Match the stretcher to your clinical environment, patient profile, and space constraints, maintain it well, and it will serve you faithfully for years.

For more selection tips, see our in-depth guide: An Essential Guide to Choosing the Right Medical Stretcher.