An Essential Guide to Comparing Mortuary Stretchers

Why Mortuary Stretchers Are Essential for Professional Funeral Operations

Mortuary-stretchers are specialized transport equipment designed for safely moving deceased individuals in funeral homes, hospitals, and removal services. These professional-grade stretchers differ from standard medical equipment through their improved durability, higher weight capacities, and features specifically engineered for dignified transport.

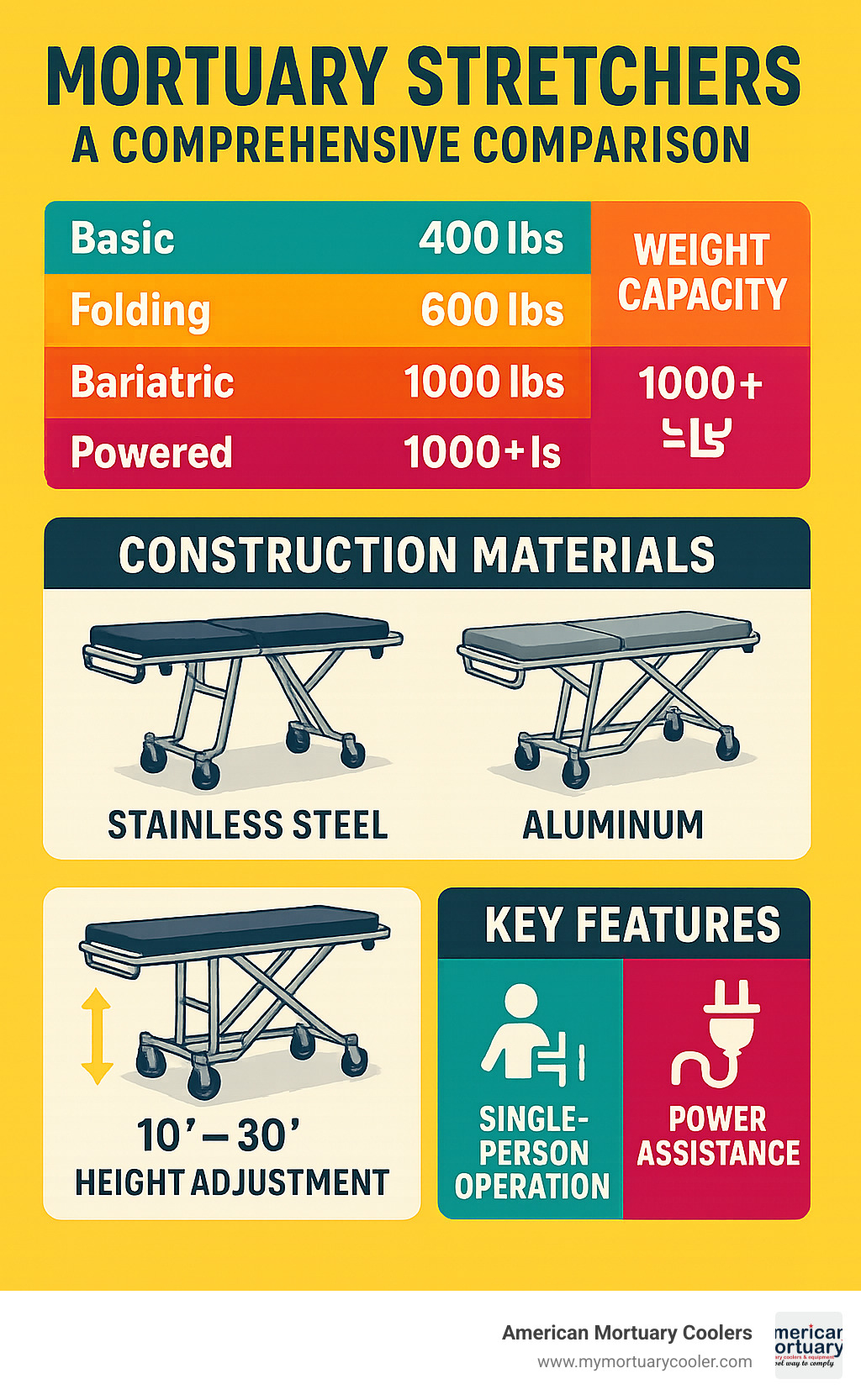

Key mortuary-stretcher specifications at a glance:

- Weight capacity: 400-1000+ lbs depending on model type

- Materials: Stainless steel or anodized aluminum construction

- Operation: Single-person or power-assisted models available

- Height range: Typically 9-32 inches with multi-level adjustment

- Standard dimensions: 76-78" length x 19-21" width

- Price range: $1,095 for basic models to $4,400+ for premium units

Modern funeral operations depend on reliable mortuary stretchers for efficient workflow. Whether you're transporting from a residence to your facility or moving between preparation rooms, the right stretcher reduces physical strain on staff while maintaining the dignity families expect.

The mortuary equipment market offers over 25 different stretcher models from leading manufacturers like Ferno, Junkin, and MOBI. Each serves different needs—from basic transport to specialized bariatric or power-assisted units.

I'm Mortuary Cooler, a mortuary equipment supplier with extensive experience helping funeral homes select the right mortuary-stretchers for their specific operational needs. My background in equipment distribution shows how the correct stretcher choice improves both staff efficiency and service quality.

Mortuary-stretchers glossary:

Mortuary Stretchers 101: Purpose, Types & Materials

The story of mortuary-stretchers begins in the early 1900s, when funeral service was changing from a family affair into a professional industry. As funeral homes became more established, they needed equipment that went beyond basic medical stretchers - something built specifically for their unique needs.

Today's mortuary-stretchers serve one primary purpose: safely transporting deceased individuals while protecting both dignity and health. It sounds simple, but the engineering behind this goal is quite sophisticated.

Three main environments rely on these specialized stretchers daily. Funeral homes use them for everyday operations - moving between preparation rooms, loading hearses, and handling transfers. Hospitals depend on them for morgue-to-transport situations, where reliability can't be questioned. Removal services need them for first-call situations, often in challenging locations where standard equipment simply won't work.

The materials that go into building these stretchers make all the difference in how long they'll serve you. Stainless steel, particularly the 304-grade variety, offers superior corrosion resistance and easy cleaning - absolutely essential when you're dealing with bodily fluids and strong disinfectants. Anodized aluminum provides a lighter alternative that won't oxidize, and as one manufacturer puts it, these stretchers "will keep looking like new for years."

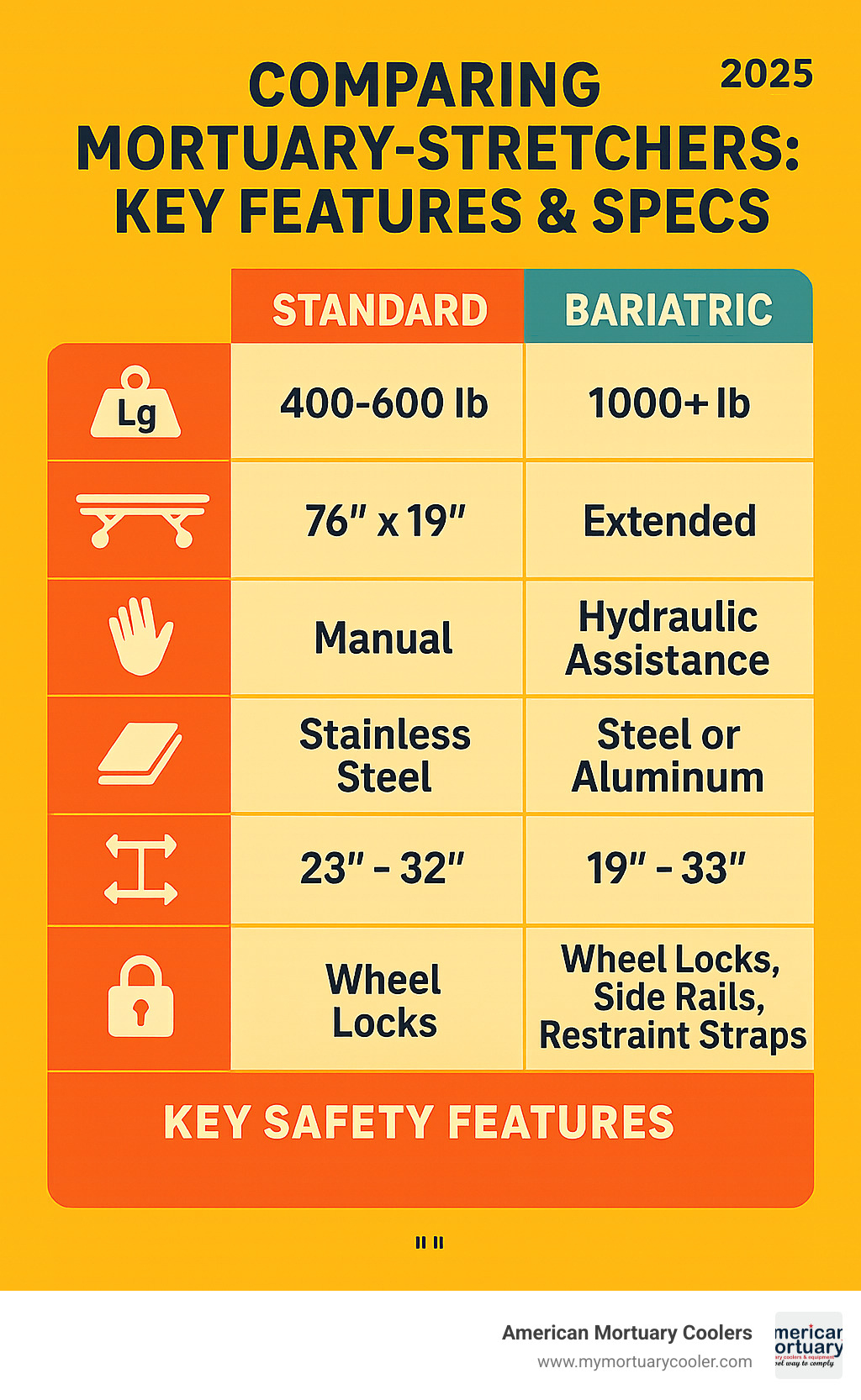

The variety of stretcher types available today reflects how diverse funeral operations have become. Standard models handle your everyday transport needs reliably. Bariatric models step up to accommodate weights exceeding 1000 pounds - a growing necessity in today's market. Folding stretchers work perfectly for emergency situations or when storage space is tight. Scoop stretchers allow transfers with minimal disturbance, while multi-level cots offer height adjustment from 9 to 32 inches.

Power and electric units represent the cutting edge of stretcher technology. Models like the MOBI P600 feature lithium batteries for electrically-assisted operation, dramatically reducing physical strain while maintaining the precise control that dignified handling requires.

Here's what sets mortuary-stretchers apart from standard medical cots: medical stretchers focus on patient comfort and emergency access, while mortuary equipment emphasizes durability, higher weight capacities, and specialized features like built-in stair guides for those tricky removal situations we've all encountered.

Standard dimensions typically measure 76-78 inches long and 19-21 inches wide, though bariatric models extend these measurements significantly. Weight capacities start at 400 pounds for standard models and climb over 1000 pounds for specialized bariatric units.

Standard & Multi-Level Designs

The biggest game-changer in mortuary stretcher design has been one-person operation. As one industry expert explains, "Most mainstream mortuary stretchers are designed for one-man operation," which dramatically cuts staffing requirements and costs during removals.

Take the Ferno Model 24, for example. It offers up to 6 different height levels, allowing one person to easily handle retrievals at various heights. This multi-level feature solves one of funeral service's most common headaches: matching stretcher height to different vehicles, tables, and facilities.

Roll-in style cots provide seamless integration with hearses and removal vehicles. Instead of lifting and manual positioning, the stretcher rolls directly into the vehicle where automatic mechanisms lock it securely in place. It's neat in its simplicity.

Height adjustment typically ranges from 9.25 inches at minimum to 32.25 inches at maximum. This range handles everything from low-profile sports cars to high-floor commercial vehicles. The loading height - usually around 24 inches - hits that sweet spot for ergonomic transfers.

Vehicle loading represents a critical design consideration that manufacturers have solved cleverly. Modern stretchers feature convertible undercarriages that transform from a multi-level platform into a two-wheeled stretcher configuration. This versatility proves essential when navigating tight spaces or unusual architectural challenges during removals.

Power, Bariatric & Oversized Options

Lithium battery technology has revolutionized how mortuary stretchers operate. Units like the MOBI P600 Power Mortuary Cot run electrically, providing consistent lifting power regardless of operator strength or fatigue levels. These systems typically offer multiple hours of operation per charge - enough for a full day's work.

Bariatric models address the growing need for higher weight capacities. With load limits exceeding 1000 pounds, these stretchers feature reinforced frames built from heavy-duty welded steel. The engineering challenges of supporting such weights while maintaining maneuverability have sparked innovations in wheel design, frame geometry, and hydraulic systems.

Hydraulic assist technology takes the physical demands out of stretcher operation. Rather than relying solely on manual lifting, hydraulic systems provide mechanical advantage during height adjustments and loading operations. This technology shines when handling maximum weight loads or when staff fatigue becomes a factor.

Bariatric transport often requires oversized platforms to accommodate individuals whose dimensions exceed standard stretcher widths. These specialized units feature wider platforms and extended length options, though they may require specialized vehicles for transport.

Construction Materials & Durability

304 stainless steel represents the gold standard for mortuary stretcher construction. This grade offers excellent corrosion resistance - essential when dealing with bodily fluids and frequent cleaning with harsh disinfectants. The material's non-porous surface prevents bacterial growth and makes thorough sanitization possible.

Welded steel frames provide the structural integrity necessary for high weight capacities. The welding process eliminates mechanical joints that might fail under stress, creating a solid structure capable of handling extreme loads safely.

Corrosion resistance extends beyond just the primary frame materials. Hardware, fasteners, and mechanical components must all resist degradation from cleaning chemicals and environmental exposure. Quality manufacturers specify marine-grade or medical-grade components throughout their designs.

Easy-clean surfaces represent a critical design requirement that affects daily operations. Smooth, non-porous materials with minimal crevices or joints simplify the cleaning process and ensure thorough disinfection. Some manufacturers even incorporate antimicrobial coatings for additional protection against bacterial growth.

Reinforced legs and support structures distribute weight loads safely across the entire frame. These components often feature automatic locking mechanisms that engage when the stretcher is deployed, preventing accidental collapse during use - a safety feature that provides peace of mind during every transfer.

Comparing mortuary-stretchers: Key Features & Specs

When you're shopping for mortuary-stretchers, the weight capacity should be your first consideration. Think of it as the foundation everything else builds on. Standard models handle 400-600 pounds comfortably, which covers most situations you'll encounter. But if you're looking at bariatric needs, you'll want units that can manage over 1000 pounds safely.

Here's something many funeral directors learn the hard way: always work well below the maximum rating. If a stretcher claims 600 pounds, treat 450 as your practical limit. This gives you that safety buffer that protects both your staff and your equipment investment.

Dimensions matter more than you might think. Those standard measurements of 76-78 inches long and 19-21 inches wide aren't arbitrary - they're designed to fit through standard doorways while providing adequate support. But here's where it gets tricky with bariatric models. They're wider and sometimes longer, which means you need to double-check they'll actually fit in your vehicles and through your facility.

The collapsible undercarriage is one of those features that seems simple until you really need it. Take the Ferno Model 24 - it transforms from a multi-level cot into a two-wheeled stretcher when you're dealing with stairs or tight spaces. It's like having two pieces of equipment in one, which is incredibly valuable during challenging removals.

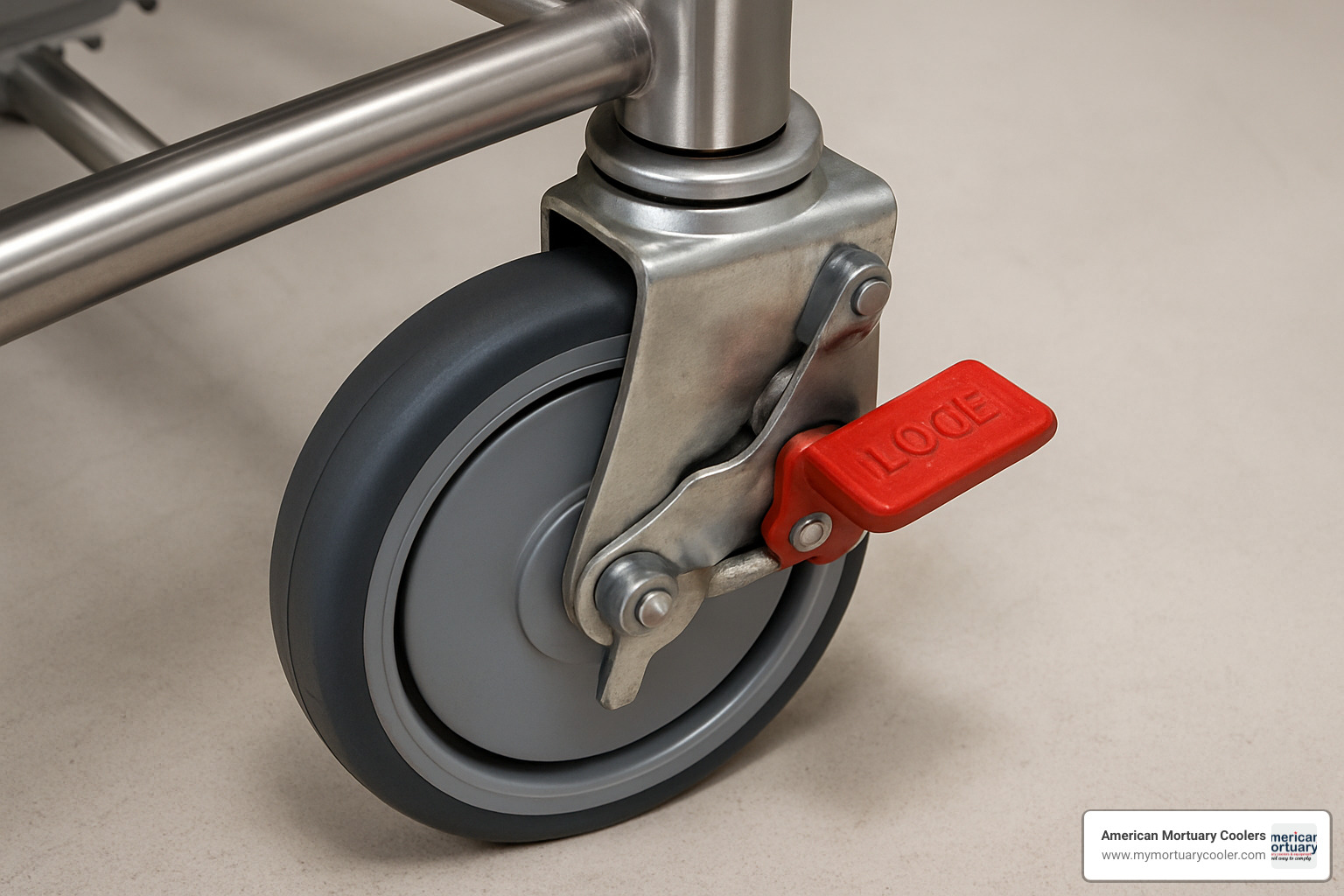

Wheel locks might seem basic, but they're absolutely critical. You want systems that lock positively and give you clear feedback when they're engaged. Some of the newer models have automatic locks that engage when weight hits the platform - pretty clever engineering that removes one more thing you have to remember during stressful situations.

Side rails and restraint straps provide that extra security during transport. While they're not always mandatory, they prevent shifting during vehicle transport and give you peace of mind when navigating uneven ground or stairs. Quality mattress pads serve double duty - they maintain dignity while providing a fluid-resistant, easy-to-clean surface.

One feature that really sets professional units apart is built-in stair guides. If you've ever had to steer a steep staircase during a removal, you know how valuable controlled descent capability can be. These guides maintain stretcher stability while keeping your operators safe.

Certifications from FDA, CE, and ISO organizations aren't just paperwork - they're your assurance that the equipment meets rigorous safety and quality standards. When you're investing thousands of dollars in equipment that your staff depends on daily, these certifications matter.

The ergonomic design directly impacts your team's wellbeing. Features like adjustable handles, intuitive controls, and balanced weight distribution reduce fatigue and injury risk. After all, your staff might use these stretchers multiple times per day, so comfort and ease of operation aren't luxuries - they're necessities.

Understanding these specifications helps you make decisions that'll serve your operation for years. For a deeper dive into matching specific models to your needs, check out our comprehensive The Ultimate Guide to Choosing the Right Mortuary Stretcher.

Must-Have Safety Features in mortuary-stretchers

Brake systems are absolutely non-negotiable when it comes to stretcher safety. You need dual-wheel engagement with positive locking mechanisms that engage easily but require deliberate action to release. The last thing you want is accidental movement during a transfer - it's both dangerous and undignified.

Integrated straps eliminate the hassle of separate restraint systems while ensuring consistent security. Built-in restraints streamline your operation and accommodate various body sizes while maintaining dignity throughout transport. No more hunting around for straps or dealing with worn-out separate restraint equipment.

Quality cot covers serve both hygiene and dignity purposes. Look for fluid-resistant materials with secure attachment systems. Some manufacturers now offer antimicrobial treatments for additional protection, which is particularly valuable given today's heightened awareness of infection control.

High-visibility latches and controls become crucial during those middle-of-the-night removal calls. Color-coding and tactile differentiation help your operators identify controls quickly and accurately, even in poor lighting conditions. It's one of those features you don't think about until you really need it.

Don't overlook additional safety features like rounded corners to prevent injury, non-slip surfaces on platforms and steps, and emergency release mechanisms for rapid deployment. These details separate professional-grade equipment from basic models.

Specialized mortuary-stretchers for Bariatric & High-Loading Needs

Bariatric mortuary-stretchers represent specialized engineering designed for our changing demographics. These units feature reinforced frames constructed from heavy-duty welded steel, capable of supporting loads exceeding 1000 pounds safely. It's not just about making things bigger - it's about completely rethinking the structural engineering.

Dual-end controls become essential when you need coordinated operation between two operators. These systems allow synchronized height adjustment and movement control, which is crucial when handling maximum weight loads or navigating challenging environments. It's like having a conversation between the operators through the equipment itself.

The wider platforms accommodate individuals whose dimensions exceed standard stretcher capacities. These platforms extend width by several inches while maintaining structural integrity and maneuverability - no small engineering feat when you consider the physics involved.

Reinforced wheel systems distribute weight loads across multiple contact points. Heavy-duty casters with larger diameters roll more easily under load while providing greater stability during transport. It's amazing how much difference proper wheel engineering makes when you're dealing with significant weight.

Power assistance becomes particularly valuable in bariatric applications. Electric or hydraulic systems provide consistent lifting power regardless of load weight, reducing operator strain and injury risk. When you're dealing with maximum capacities, human strength alone often isn't enough for safe operation.

The field continues to evolve as manufacturers invest in research focused on reducing operator strain while maintaining equipment reliability and safety margins.

Cost, Brands, Purchase & Compliance Guide

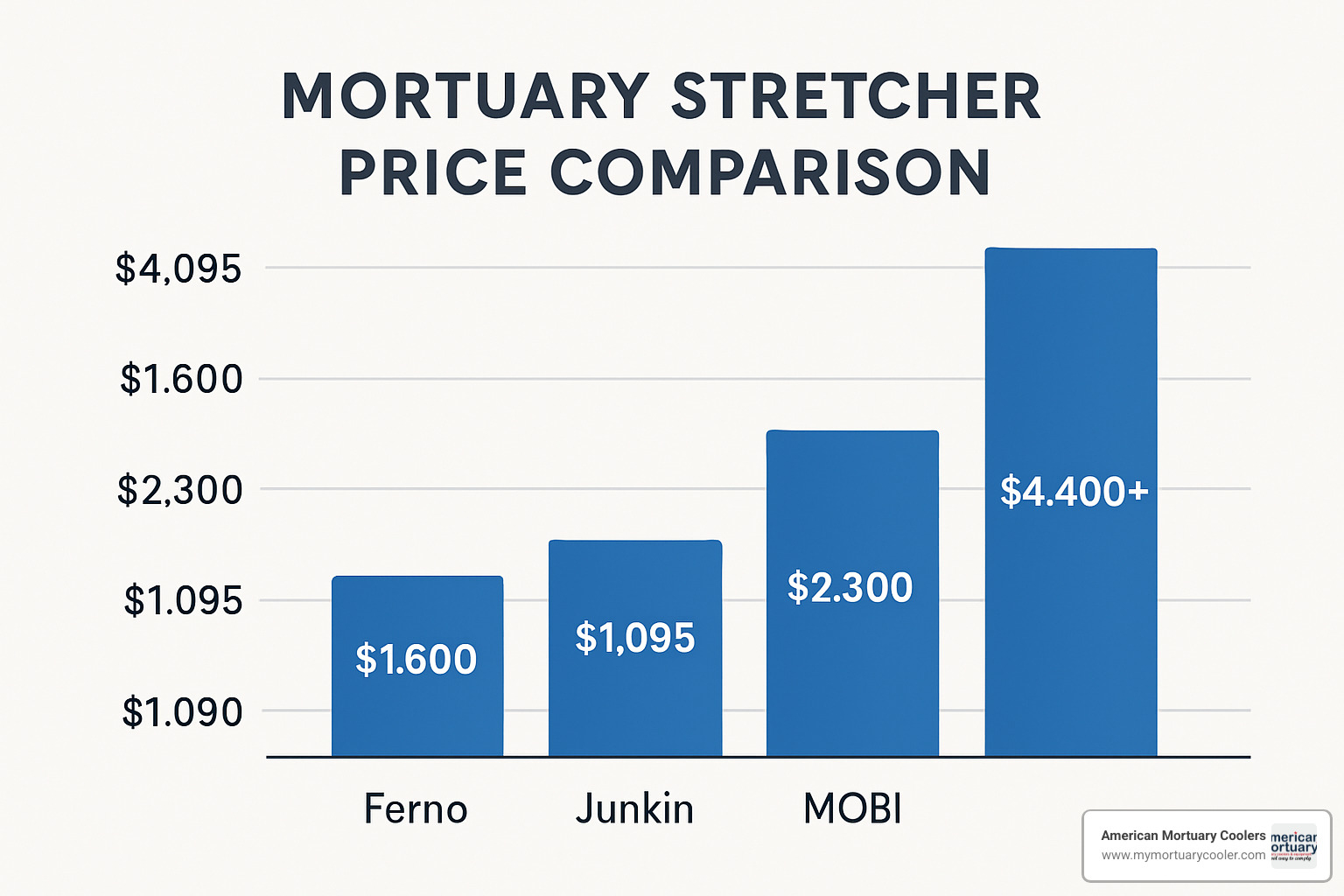

Shopping for mortuary-stretchers means navigating a market that ranges from practical basics to premium powerhouses. You'll find entry-level models starting around $1,095, while top-tier units with all the bells and whistles can reach $4,400 or more. The price difference isn't just about fancy features - it reflects real differences in materials, engineering, and the kind of daily punishment these stretchers can handle.

The new versus used decision comes down to your comfort level with risk versus reward. New stretchers arrive with full warranties and the latest safety improvements, giving you peace of mind but requiring a bigger upfront investment. Used equipment can slash your costs significantly, though you'll want to inspect wear points and safety systems carefully - nobody wants a stretcher failure during a removal.

Ferno dominates the landscape with over 25 different first-call cot models, more variety than most facilities know what to do with. Their Model 24 Mortuary Cot sits at the premium end at $3,297.95 (marked down from $4,228.00), showcasing the multi-level design and comprehensive features that justify the investment for busy operations.

Junkin offers solid alternatives across multiple price points, from no-frills basic units to specialized "Tall" and oversized models. They've built their reputation on delivering reliable equipment without the premium price tag, making them popular with cost-conscious facilities.

MOBI has carved out their niche through innovation, particularly their P600 Power Mortuary Cot with lithium battery operation. If your staff is tired of wrestling heavy loads up vehicle ramps, their power-assisted approach might be worth the extra investment.

Warranty coverage typically includes 2 years on the hard goods (frames, mechanisms, wheels) and 90 days on soft goods (mattresses, straps, covers). This difference makes sense when you consider that structural components should last for years, while fabric items face daily wear and cleaning cycles.

Financing options can ease the budget pain, letting you spread equipment costs over time rather than taking a big hit all at once. Many suppliers understand that funeral homes operate on tight margins and offer payment plans that work with your cash flow.

Online suppliers make it easy to browse specifications and compare prices from your office, though the complexity of choosing the right mortuary-stretchers often benefits from talking with someone who knows the business. Specialized distributors bring expertise in matching equipment to your specific needs - they understand the difference between a high-volume urban operation and a small rural facility.

Compliance requirements vary depending on where you operate, but you'll typically need to meet OSHA workplace safety standards, ASTM material and performance specifications, and whatever your local health department requires. These standards cover everything from weight capacity testing to ensuring materials won't cause adverse reactions.

Cleaning protocols need to handle both routine maintenance and those unfortunate situations requiring serious decontamination. Your local regulations will specify approved disinfectants and cleaning procedures, but they all emphasize preventing cross-contamination and maintaining the hygiene standards families expect.

Storage best practices protect your investment while keeping equipment ready for action. This means climate-controlled storage when possible, regular inspection schedules, and keeping moving parts and safety systems properly maintained. A well-maintained stretcher can serve reliably for many years, while neglect can lead to expensive repairs or dangerous failures.

For a broader perspective on the equipment market and emerging trends, check out our comprehensive analysis in Explore the Stretchers and Cot Market: Ultimate Guide to Camping Cots and Stretcher Types.

Frequently Asked Questions about mortuary-stretchers

What regulations must a mortuary stretcher meet?

Mortuary-stretchers steer a complex web of regulations that protect both funeral service workers and the families they serve. Understanding these requirements helps ensure your facility stays compliant while providing safe, professional service.

OSHA workplace safety standards form the foundation of stretcher regulations. These rules focus on protecting your staff from injury during daily operations. They require proper lifting mechanisms, safety features that reduce back strain, and equipment designed to minimize workplace injuries.

ASTM International standards get into the technical details that matter for day-to-day use. These specifications cover weight capacity testing (so you know a 600-pound rating actually means 600 pounds), durability requirements, and material safety. When a stretcher manufacturer claims their product meets ASTM standards, they're telling you it's been properly tested under controlled conditions.

FDA regulations can apply to certain stretcher components, especially those classified as medical devices. While not all mortuary stretchers fall under FDA oversight, some features or materials might trigger these requirements.

Local health departments often have the most specific rules you'll encounter. They typically mandate cleaning protocols, specify which disinfectants you must use, and require documentation of your maintenance procedures. These regulations vary significantly by state and county, so check with your local authorities.

State funeral service licensing boards may also weigh in on equipment requirements. These rules usually reference national standards but sometimes add local requirements based on regional needs or concerns.

How do I disinfect and store a mortuary stretcher properly?

Proper cleaning and storage of your mortuary-stretchers protects both your investment and your reputation. The process is straightforward, but attention to detail makes all the difference.

Start with thorough cleaning before you even think about disinfection. Remove all visible contamination using appropriate cleaning solutions. This step is crucial because disinfectants can't work properly on dirty surfaces.

Use hospital-grade disinfectants that are proven effective against a broad spectrum of pathogens. Make sure your chosen products are compatible with your stretcher's materials - some harsh chemicals can damage finishes or compromise structural components over time.

Pay special attention to joints, crevices, and moving parts where contamination tends to hide. These areas often get overlooked during routine cleaning but can harbor dangerous pathogens. Remove mattresses, straps, and other detachable components for separate cleaning according to manufacturer specifications.

Allow proper contact time for your disinfectant to do its job. This typically ranges from 30 seconds to several minutes, depending on the product and what you're trying to eliminate. Don't rush this step - it's where the actual disinfection happens.

Storage requires a clean, dry environment protected from temperature extremes and excessive humidity. These conditions prevent corrosion and maintain the integrity of moving parts and safety systems.

Keep detailed maintenance logs documenting every cleaning, inspection, and repair. These records satisfy regulatory requirements, support warranty claims, and help you spot patterns that might indicate operational issues or the need for equipment replacement.

Where can I buy quality mortuary stretchers online?

Finding reliable mortuary-stretchers online requires knowing where to look and what questions to ask. The specialized nature of this equipment means not all suppliers understand the unique demands of funeral service.

Specialized medical equipment distributors often provide the best combination of product knowledge and competitive pricing. These companies understand funeral service operations and can help match equipment to your specific needs. They typically carry multiple brands, making comparison shopping easier.

Manufacturer direct sales give you access to complete product lines and factory support. Companies like Ferno, Junkin, and MOBI offer direct purchasing, though pricing might not be as competitive as through distributors. The advantage lies in getting exactly what you need with full factory backing.

Online marketplaces like eBay can offer significant savings, especially on used equipment. However, buyer expertise becomes critical when evaluating condition and suitability. Used stretchers require careful inspection of safety systems, moving parts, and structural integrity.

Regional suppliers often provide advantages beyond just pricing. They understand local regulations, offer faster shipping, and can provide hands-on support when needed. Many also offer trade-in programs when you're ready to upgrade.

When evaluating any supplier, look beyond the price tag. Consider warranty support, technical expertise, parts availability, and the supplier's long-term stability. The specialized nature of mortuary equipment makes supplier reliability particularly important - you need to know they'll be there when you need service or replacement parts.

At American Mortuary Coolers, we understand the importance of reliable equipment suppliers. While we specialize in custom mortuary coolers, we know how critical it is to work with knowledgeable partners who understand the funeral industry's unique requirements.

Conclusion

Choosing the right mortuary-stretchers comes down to understanding your daily operations and matching them with equipment that won't let you down. With prices spanning from $1,095 for basic models to over $4,400 for power-assisted units, there's a solution for every funeral home's needs and budget.

At American Mortuary Coolers, we've spent years helping funeral homes across Tennessee and the entire contiguous 48 states find equipment that actually works for their specific situations. We know that buying a mortuary stretcher isn't just about checking boxes on a spec sheet - it's about investing in equipment that keeps your staff safe and maintains the dignity families deserve.

What sets us apart is our custom approach. We don't just sell you what's in the catalog. Instead, we take time to understand how your facility operates, what challenges you face during removals, and what features will actually make your job easier. Whether you're dealing with narrow hallways, heavy-duty transport needs, or budget constraints, we work with you to find the right solution.

Our quality assurance matters because mortuary equipment has to perform when it counts. You can't afford a stretcher failure during a removal, and families trust you to handle their loved ones with care and professionalism. That's why we focus on durable, professionally-engineered solutions that stand up to daily use while meeting the safety standards your operation requires.

Custom builds represent one of our strongest capabilities. When standard equipment doesn't fit your unique needs, we can work with manufacturers to modify specifications or create entirely custom solutions. This flexibility has helped facilities handle everything from unusual architectural challenges to specialized transport requirements.

Our nationwide delivery network means you get reliable equipment no matter where you're located. With locations spanning from Johnson City TN to Los Angeles, and coverage throughout the Midwest, Northeast, Rocky Mountain, Southeast, Southwest, and Pacific regions, we're positioned to support your equipment needs with responsive service.

Ready to upgrade your mortuary stretcher capability? We encourage you to contact us directly for a consultation. Our technical expertise helps identify the specific features and weight capacities that match your operational needs, ensuring you get equipment that justifies the investment through years of reliable service.

Contact American Mortuary Coolers today to explore our complete range of mortuary stretcher options and discuss custom solutions for your facility. Our team understands the funeral industry's unique requirements and we're committed to helping you find equipment that improves both operational efficiency and service quality.

For detailed product comparisons and selection guidance, check out our comprehensive resource: The Ultimate Guide to Top-Rated Mortuary Stretchers.