Beginner's Guide to Hydraulic Lifts: How They Work and Their Uses

Why Understanding Hydraulic Lifts Matters for Your Business

A hydralic lift is a mechanical device that uses pressurized fluid to raise and lower heavy loads, operating on Pascal's principle of pressure transmission through incompressible liquids. These versatile lifting systems are essential equipment across industries from automotive shops to funeral homes, warehouses to medical facilities.

Quick Answer: What is a Hydraulic Lift?

- Definition: Device using fluid pressure to lift heavy objects vertically

- Key Components: Pump, cylinder, piston, oil reservoir, control valves

- Weight Capacity: From 10 lbs to 6,000 lbs depending on model

- Speed: Up to 150 feet per minute (slower than traction lifts)

- Applications: Car lifts, patient lifts, material handling, elevators

- Main Advantage: Lower installation cost and compact footprint

- Primary Limitation: Generally restricted to 2-level applications

Whether you're lifting vehicles in an automotive shop, moving heavy equipment in a warehouse, or positioning patients in a medical facility, hydraulic lifts offer a cost-effective and reliable solution for vertical material handling. They require about 10% less shaft space than other elevator types and don't need separate machine rooms in many configurations.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in hydraulic lift systems for funeral homes and medical facilities. My expertise with hydralic lift technology has helped countless funeral directors choose the right lifting solutions for their specific needs.

Hydralic lift word guide:

Understanding the Hydralic Lift Mechanism

Every hydralic lift operates on Pascal's law - pressure applied to confined fluid spreads equally in all directions. This means a small force on a tiny piston can create enormous lifting power through a larger cylinder.

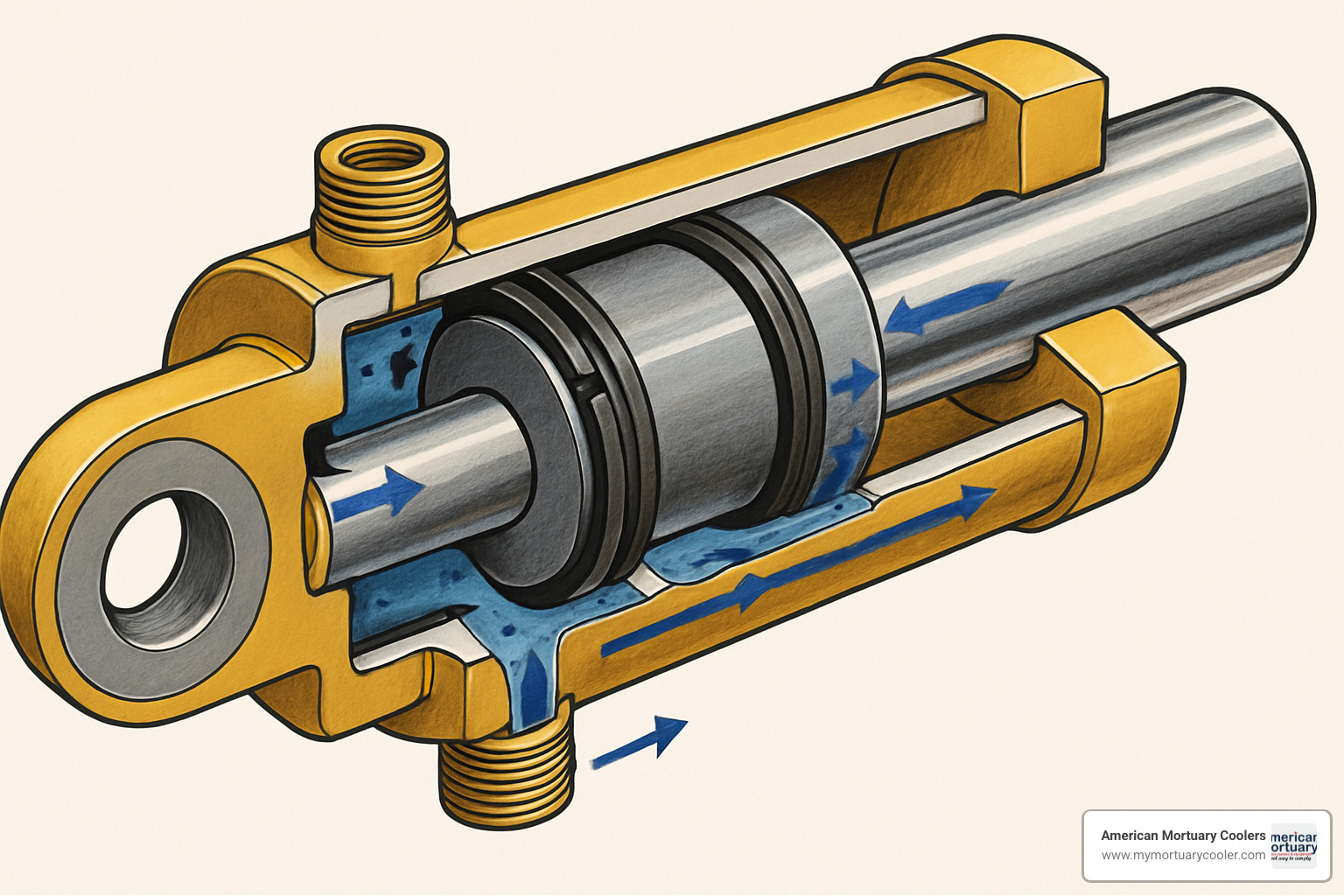

The heart of any hydraulic system contains several key components working together. The hydraulic cylinder and piston act as the muscle, where fluid pressure transforms into lifting force. An electric pump forces hydraulic fluid into the cylinder to build pressure. The oil reservoir stores the incompressible fluid, while control valves manage fluid flow for smooth operation.

Hoses and fittings connect everything together, and safety devices including velocity fuses and check valves prevent catastrophic failures. These safety features are critical for protecting equipment and operators.

For more detailed information about hydraulic pump systems, check out our guide on Hydraulic Pump Essentials.

What is a Hydralic Lift?

A hydralic lift is any device that uses pressurized fluid instead of cables, chains, or gears to move things up and down. The first hydraulic elevators appeared in the mid-1800s, with Elisha Graves Otis creating the first safety elevator in 1852.

Modern hydraulic lifts use refined oils, precision-engineered cylinders, and electronic controls to deliver smooth operation. The genius of Pascal's principle becomes clear when you see it in action - apply pressure to a small area, and that pressure travels through the entire fluid system, multiplying force dramatically.

For a deeper dive into the scientific principles, NASA provides excellent educational resources on Pascal's principle.

How Does a Hydralic Lift Work?

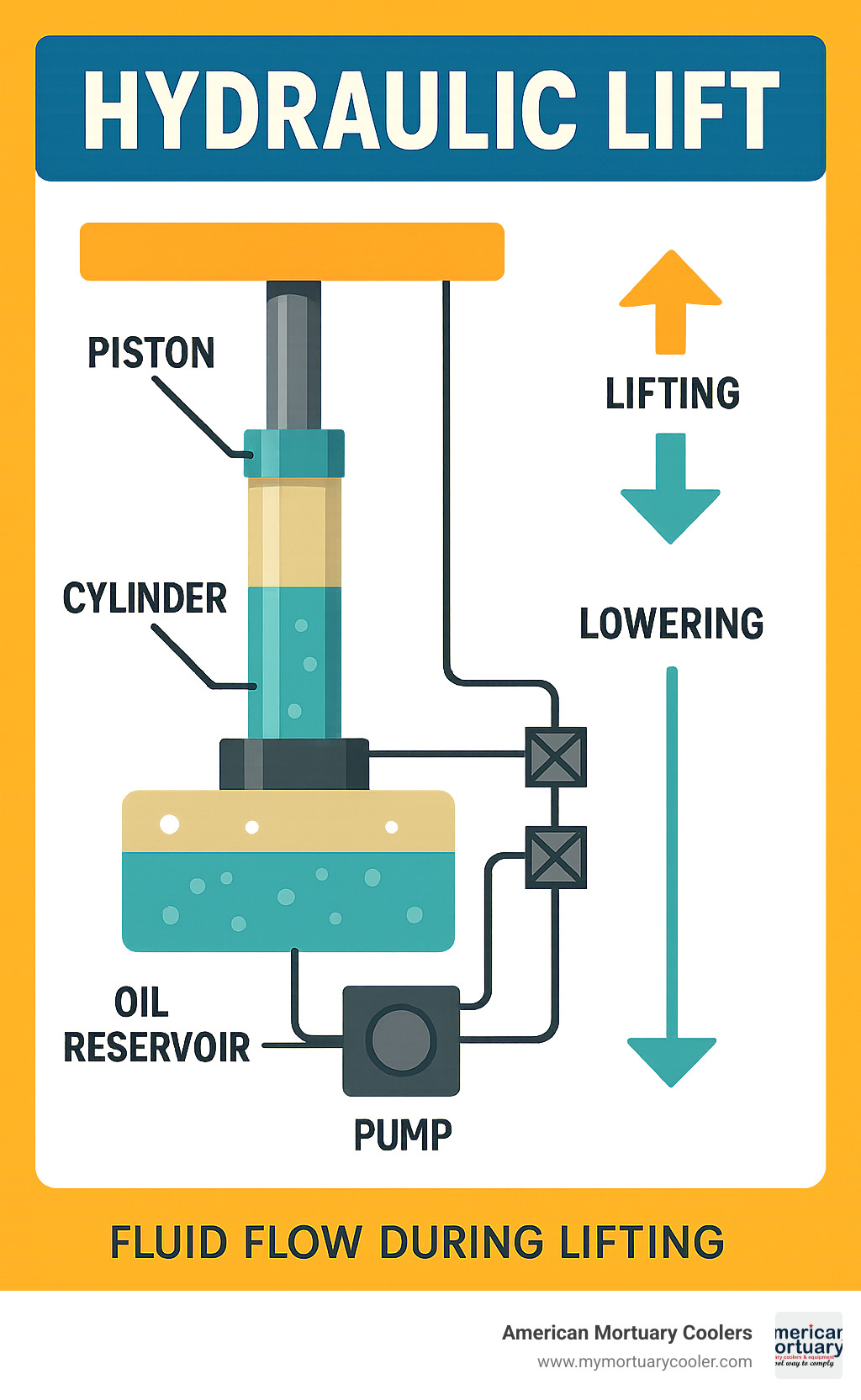

The operation of a hydralic lift follows a simple sequence. During the lifting phase, the electric pump forces hydraulic fluid from the reservoir into the cylinder, pushing the piston upward with tremendous force. When the lift reaches the desired height, the control valve closes to lock everything in position.

The lowering phase works with gravity. The control valve opens to release fluid pressure, allowing the load's weight to push the piston down while fluid returns to the reservoir. Flow control valves manage descent speed for smooth operation.

What makes this system reliable is that hydraulic fluid won't compress under pressure. Unlike air, oil maintains its volume and transmits force directly to the lifting mechanism. Modern systems include velocity fuses that stop fluid flow if descent speed gets too fast, and check valves that prevent drops during power failures.

Types & Real-World Applications

Hydralic lift systems have found their way into virtually every industry because they solve a universal problem: how to move heavy things up and down safely and efficiently.

The beauty of hydraulic technology lies in its adaptability. Whether you need a scissor lift raising pallets in a warehouse, a platform lift moving materials between floors, or a specialized patient lift in a hospital, the same basic principles apply.

Vertical Reciprocating Conveyors (VRCs) represent the workhorses of industrial lifting, typically handling up to 6,000 pounds between two levels. Patient lifts focus on gentle, controlled movement for healthcare applications, usually supporting around 400 pounds. Automotive lifts come in various configurations from simple scissor designs to massive four-post systems.

The marine industry uses hydraulic boat lifts that handle everything from small watercraft to massive yachts weighing 36,000 pounds or more. Specialized applications like mortuary lifts require unique features for funeral service work.

For comprehensive information about mortuary-specific applications, our guide to Mortuary Lift Products covers the unique requirements of funeral industry equipment.

Two-Level Material Lifts (VRCs)

Hydraulic VRCs excel at moving materials between exactly two levels. These systems can handle impressive loads - 6,000-pound capacity models are common in industrial settings, with platforms often measuring 12 feet by 10 feet to accommodate standard pallets.

The duty cycle is important - most hydraulic VRCs handle about 10 cycles per hour or 100 cycles per day. The lifting speed of around 24 feet per minute balances efficiency with smooth operation.

What makes hydraulic VRCs attractive is their cost-effectiveness for two-level applications. They require less overhead space and often cost significantly less to install. When floor space is tight, the pump can be located remotely.

For funeral homes requiring specialized lifting solutions, our guide to Reliable Body Lifts provides mortuary-specific information.

Accessibility & Medical Uses

Healthcare environments demand hydralic lift systems that prioritize safety, comfort, and precise control. Patient lifts typically support up to 400 pounds safely, with lift ranges from 24 inches to 75 inches in height.

The hydraulic advantage shines in patient care - smooth, controlled movement eliminates jarring motion that mechanical lifts sometimes produce. This is crucial when transferring patients who may be in pain or have fragile medical conditions.

Emergency lowering systems are standard on medical hydraulic lifts. If power fails, patients won't be left suspended - the system can be manually lowered to safety.

Automotive & Marine Uses

Hydralic lift systems dominate professional auto shops. Two-post lifts provide excellent underside access while taking minimal floor space. Four-post lifts create stable platforms for vehicle storage or maintenance. Scissor lifts work well for smaller spaces.

The hydraulic advantage becomes obvious when comparing lifting speeds - a hydraulic hoist can raise a 5,000-pound vehicle in under a minute with the push of a button.

Marine applications showcase hydraulic power on a grander scale. Cantilever boat lifts work well in shallow water, handling boats up to 36,000 pounds. Vertical lifts work better in deeper water where levels fluctuate.

Modern boat lifts feature push-button operation, solar charging options, and even Bluetooth control systems. The hydraulic system provides faster lifting than manual winch systems while requiring no permanent pilings.

Advantages, Limitations & Comparisons

Hydralic lift systems have fantastic advantages that make them the go-to choice for many applications, but they also have limitations you should know about before making a decision.

Key Benefits of a Hydralic Lift

The biggest win with hydraulic lifts is cost-effectiveness. You'll typically spend significantly less upfront compared to traction elevators, making them attractive when budgets are tight.

Space efficiency is another major advantage. These systems need about 10% less shaft area than other elevator types, and many don't require separate machine rooms. Components can be tucked away in the pit or adjacent spaces.

Don't let their compact size fool you - hydraulic lifts pack serious lifting power. Most models handle up to 6,000 pounds easily, making them perfect for heavy equipment and industrial applications.

The simple mechanics mean fewer moving parts compared to cable-driven systems. This translates to easier maintenance and more reliable operation.

Safety features are built into the hydraulic design. There's no risk of free-fall because oil trapped in the cylinder prevents sudden drops. Velocity fuses, check valves, and emergency lowering systems provide multiple safety layers.

Drawbacks & Environmental Concerns

Speed isn't hydraulic lifts' strong suit. Most hydralic lift systems max out around 150 feet per minute, which feels sluggish compared to traction elevators that can reach 500+ feet per minute.

Vertical rise restrictions are another reality. Most hydraulic systems work best for two-level applications with maximum rises around 20 to 30 meters for hole-less configurations.

Environmental concerns deserve consideration. Oil leaks can contaminate soil and groundwater if seals fail. Temperature sensitivity affects performance - hydraulic oil changes viscosity in extreme temperatures, impacting smooth operation.

Energy efficiency isn't hydraulic lifts' best feature. They consume more electricity than traction systems, particularly during lifting phases when the pump works against full load.

Hydralic vs Mechanical/Traction Lifts

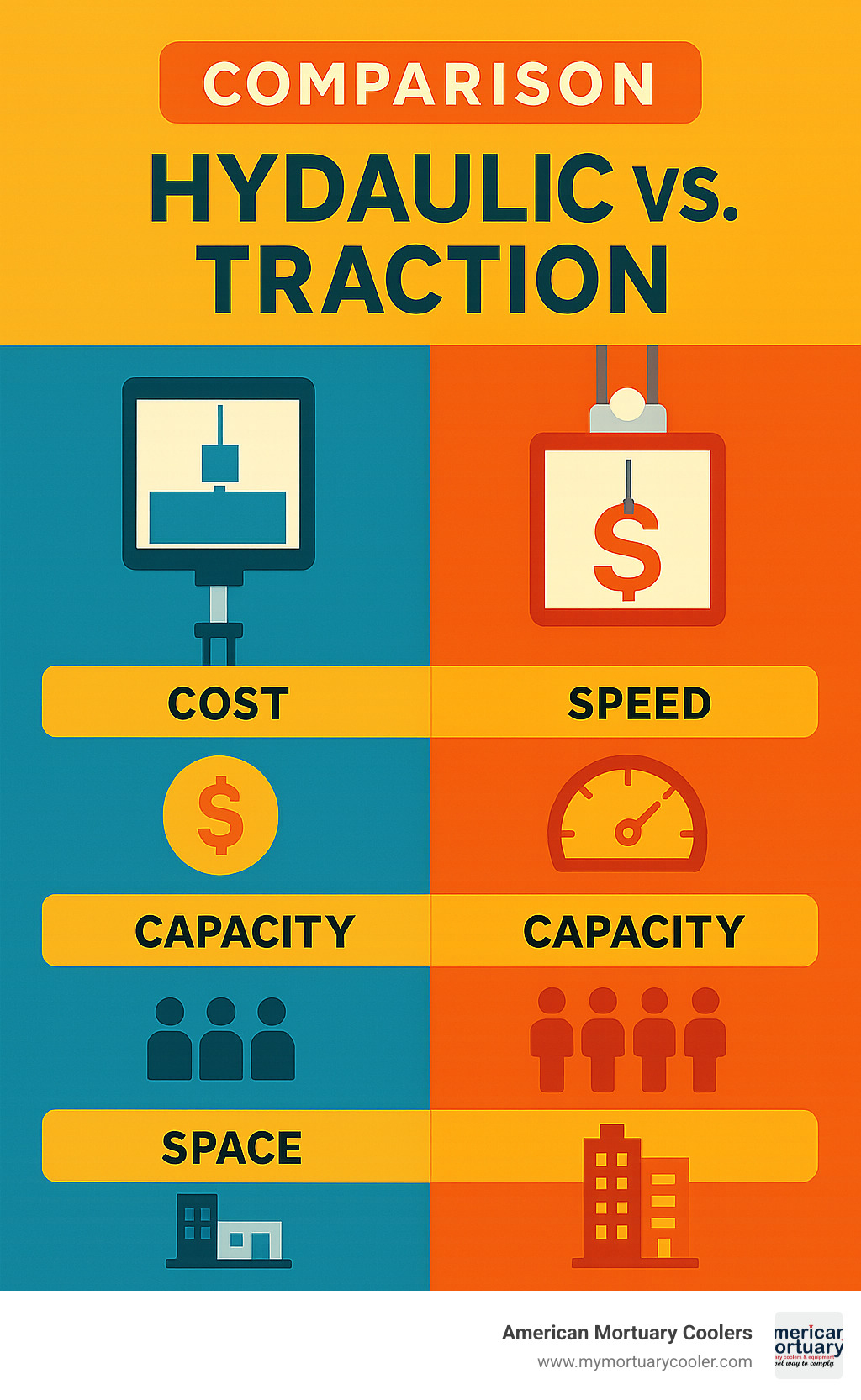

The choice between hydraulic and traction systems comes down to matching technology to your needs. Initial cost clearly favors hydraulic lifts, but traction systems offer unlimited travel height and much faster speeds up to 500+ feet per minute.

Load capacity varies by application - hydraulic lifts handle up to 6,000 pounds easily, while traction systems can accommodate even heavier loads. Space requirements favor hydraulic systems, needing 10% less shaft area and often eliminating machine room requirements.

Energy consumption patterns differ significantly. Hydraulic lifts use more power during lifting but none during holding, while traction systems maintain more consistent energy usage.

For low-rise buildings with moderate traffic, hydralic lift systems deliver excellent value. High-rise applications or heavy-traffic situations favor traction elevators despite higher initial costs.

Safety, Maintenance & Troubleshooting

When it comes to hydralic lift systems, safety isn't just important - it's absolutely critical. These powerful machines handle heavy loads under high pressure, which means proper safety protocols and regular maintenance can be the difference between smooth operation and serious accidents.

Modern hydraulic lifts come equipped with impressive safety features. Velocity fuses act like automatic brakes, instantly stopping fluid flow if the lift descends too quickly. Check valves prevent the lift from dropping during power outages by trapping oil in the cylinder.

The emergency lowering system allows controlled descent without electricity when power fails. Safety gates with interlocks ensure the system won't operate when gates are open, while overload protection prevents lifting beyond rated capacity.

OSHA standards 1926.451 and 1910.29 set the rules for hydraulic lift safety, while ANSI standards cover everything from design to inspection requirements. Regular operator training is essential for safe operation.

For funeral homes dealing with specialized lifting needs, our guide to Choosing the Best Mortuary Lift System covers safety considerations unique to mortuary environments.

Routine Maintenance Checklist

Maintaining your hydralic lift is like caring for a reliable workhorse - treat it well, and it'll serve you faithfully for years. The key is staying ahead of problems rather than reacting to them.

Monthly visual inspections should become routine. Walk around your lift looking for oil spots, checking fluid levels, and testing safety systems. Pay special attention to hoses and fittings - they're often the first to show wear.

During monthly checks, run the lift through its full travel range. Does it move smoothly? Any jerky motion or unusual noises? Test emergency stops and safety gates.

Annual maintenance includes fresh hydraulic fluid and clean oil filters. This is when you inspect and test velocity fuses and check valves that keep everyone safe. Hose inspection is crucial - look for cracking, bulging, or deterioration signs.

Five-year comprehensive service is your lift's major overhaul. Replace all hoses and fittings regardless of appearance, refresh cylinder seals, overhaul pumps, and pressure test the entire system.

Temperature control deserves attention. Overheated hydraulic oil loses viscosity and can damage system components. Proper ventilation and temperature monitoring prevent these issues.

Common Issues & Quick Fixes

Even well-maintained hydralic lift systems occasionally act up. Most problems have straightforward solutions once you understand what's happening.

Slow response usually has simple causes. Low hydraulic fluid is most common - check levels first. If fluid is adequate, the pump might be wearing out or pressure settings could be off.

Jerky motion typically means air has entered the hydraulic system or fluid is contaminated. Air compresses while oil doesn't, creating stuttering movement. Bleeding the system and replacing contaminated fluid usually restores smooth operation.

Excessive noise ranges from annoying to alarming. Cavitation in the pump creates whining sounds and indicates the pump is starving for fluid. Loose fittings create rattling, while worn components produce grinding noises.

Oil leaks start small but grow quickly. Fresh leaks often mean seal failure, which is relatively inexpensive to fix. Address leaks promptly - they can contaminate soil and groundwater.

Temperature problems usually develop gradually. Systems working beyond their duty cycle or lacking proper ventilation overheat. Ensuring proper duty cycles and adding ventilation solves most temperature issues.

Modern predictive maintenance technologies use smart sensors to continuously track pressure, temperature, and vibration, alerting operators to developing problems before they cause failures.

Frequently Asked Questions about Hydralic Lifts

How much weight can a standard hydralic lift handle?

The weight capacity of a hydralic lift varies dramatically depending on application. Patient lifts typically max out around 400 pounds - perfect for healthcare settings. Scissor lifts for material handling usually fall between 330 and 1,100 pounds, covering most warehouse needs.

Automotive lifts can handle 7,000 pounds or more - enough for most cars and light trucks. For industrial work, VRC systems can move up to 6,000 pounds reliably. Marine lifts can handle an impressive 36,000 pounds.

The golden rule is to choose a lift with at least 20% more capacity than your heaviest load. This safety margin protects both equipment and people. Actual capacity depends on cylinder size, system pressure, and platform design.

Do hydralic lifts need a separate machine room?

Most modern hydralic lift systems don't need their own machine room, which saves serious space and money. This is one of the biggest advantages hydraulic systems have over traditional traction elevators.

Machine-Room-Less (MRL) designs are now standard. The pump and controls can be tucked away in the pit below the lift or in an adjacent utility space. Some systems even let you put the machine room in a completely different part of the building.

This flexibility eliminates the need for overhead structural modifications and can reduce building space requirements by about 10%. This space-saving feature makes hydraulic lifts particularly attractive for retrofit installations where every square foot counts.

How energy-efficient are hydralic lifts compared to traction models?

Hydralic lift systems generally use more energy than traction elevators, but the real-world difference depends on how you use the system.

Hydraulic lifts consume maximum power during the lifting phase when the pump works against the full load weight. Modern systems are getting smarter about energy use - energy recovery systems can improve efficiency by 30 to 40%, and variable-speed pumps adjust output based on actual load.

For low-duty cycle applications - systems making fewer than 100 trips per day - the energy difference between hydraulic and traction systems is often negligible. High-traffic installations favor traction elevators for better energy efficiency, but for most industrial and specialized applications, the energy difference is usually offset by lower installation costs and simpler maintenance.

Conclusion

Hydralic lift technology has evolved from early steam-powered elevators to today's systems that blend time-tested hydraulic principles with innovations like smart sensors, eco-friendly fluids, and energy recovery systems.

The core advantages remain unchanged. They cost less to install than traction elevators, take up about 10% less space, and handle impressive loads while keeping maintenance relatively simple. They're not winning speed contests, and you won't see them in skyscrapers, but for two-level applications and specialized industries, they're hard to beat.

The future looks bright for hydralic lift systems. Smart sensors are revolutionizing maintenance by predicting problems before breakdowns occur. Bio-based hydraulic fluids address environmental concerns without sacrificing performance. Energy recovery systems are closing the efficiency gap with traditional elevators.

At American Mortuary Coolers, we've seen how the right hydraulic lifting solution transforms operations in funeral homes across Tennessee, Georgia, and nationwide. Every installation teaches us about matching system capabilities to real-world needs.

The beauty of hydralic lift technology lies in its versatility. From automotive shops lifting cars to hospitals moving patients safely, from warehouses handling freight to funeral homes providing dignified care - these systems adapt to countless applications while maintaining fundamental reliability.

Ongoing innovations continue addressing traditional limitations while building on proven strengths. Predictive maintenance reduces downtime, environmental improvements address sustainability concerns, and smart controls optimize performance.

For funeral professionals considering hydraulic lifting solutions, our detailed guide to Mortuary Hydraulic Body Lifts covers everything from selection criteria to maintenance best practices.

The story of hydraulic lifts is about solving problems efficiently and safely. As technology advances and industries evolve, hydralic lift systems will continue providing dependable solutions for vertical material handling challenges.