Beginner's Guide to Toothed Forceps

Understanding Toothed Forceps: Essential Surgical Instruments

Toothed forceps are specialized surgical instruments with serrated or tooth-like projections on their grasping surfaces, designed to provide a secure, non-slip grip on tissues during medical and dental procedures. These hinged instruments feature opposing jaws with small teeth that interlock when closed, allowing surgeons to manipulate tissues with precision while applying minimal pressure.

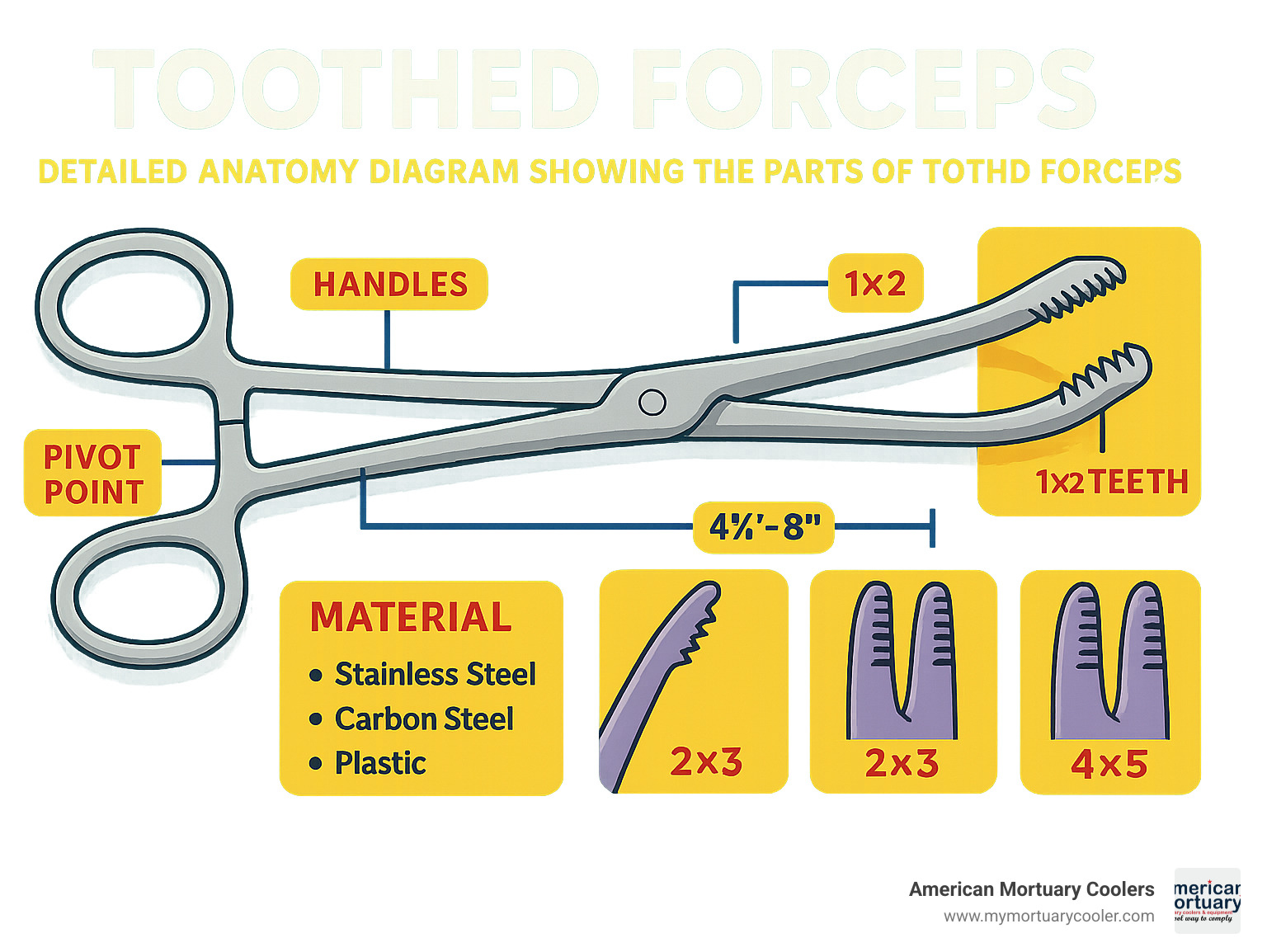

Key characteristics of toothed forceps:

- Design: Hinged instrument with tooth-like projections on jaw tips

- Purpose: Secure tissue grasping with reduced slippage

- Materials: Typically stainless steel, carbon steel, or disposable plastic

- Sizes: Range from 4¾" to 8" in length

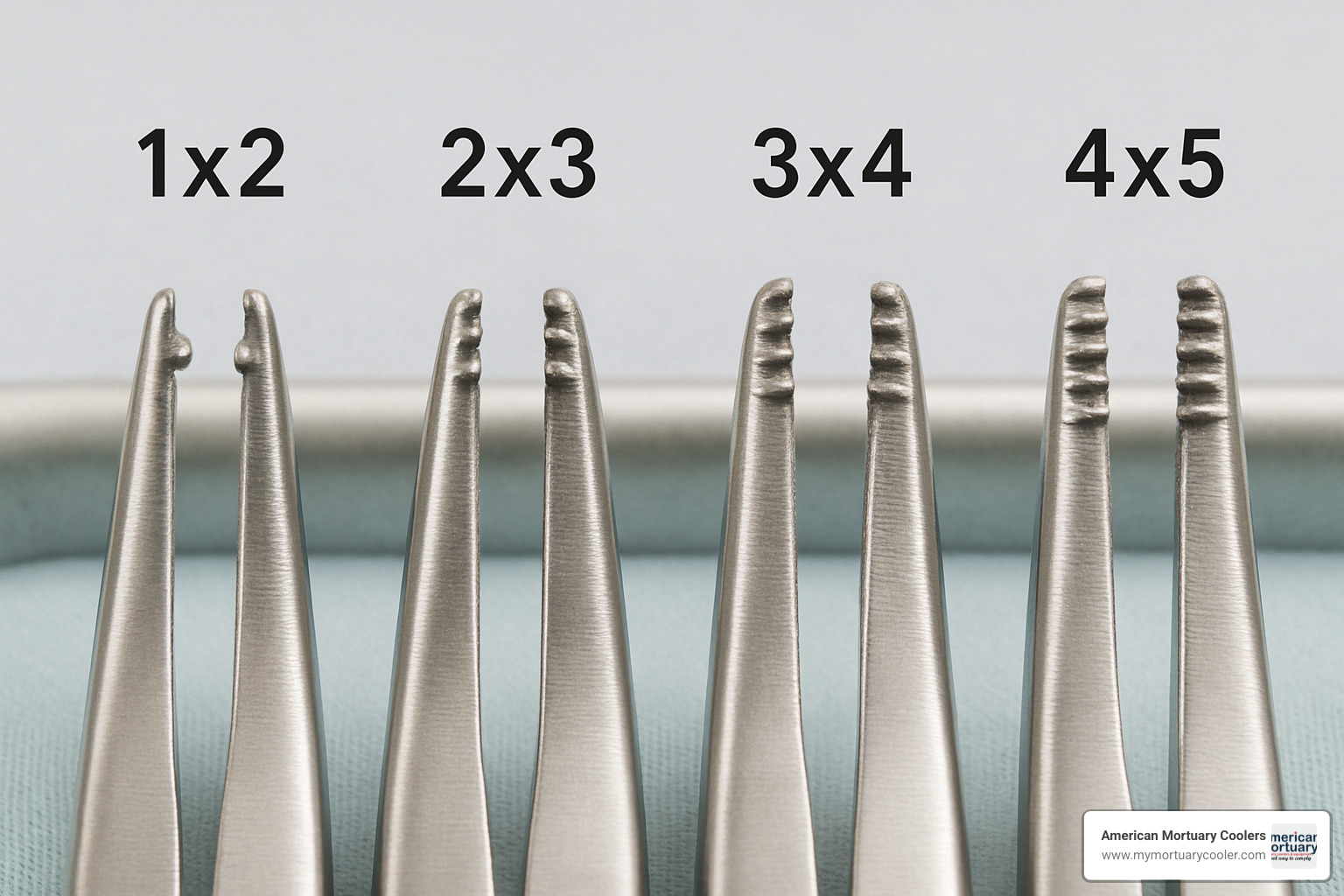

- Tooth patterns: Common configurations include 1×2, 2×3, and 4×5 teeth

- Applications: Medical surgery, dental extractions, laboratory work, and mortuary procedures

The tooth design sets these instruments apart from smooth forceps. Research shows forceps with teeth require less pressure to maintain grip, minimizing tissue damage compared to smooth forceps that need more gripping force. The first anatomical forceps were invented in 1841 by British surgeon Sir John Tomes, revolutionizing dental extraction techniques.

From ancient Egyptian wall carvings showing primitive forceps use over 2,500 years ago to today's precision-engineered instruments, toothed forceps have evolved into indispensable tools across medical, dental, and mortuary fields.

I'm Mortuary Cooler, and through years of supplying mortuary equipment nationwide, I've seen how proper understanding of surgical instruments like toothed forceps helps funeral professionals make informed equipment decisions.

What Are Toothed Forceps?

Ancient Egyptian surgeons 2,500 years ago, depicted in wall carvings, used the earliest versions of toothed forceps. These primitive instruments looked more like blacksmith tools than the precision instruments we know today, yet they marked the beginning of a surgical revolution.

The breakthrough came in 1841 when British surgeon Sir John Tomes looked at the crude "toothkey" extraction methods and thought, "There has to be a better way." The toothkey was basically a lever that often broke jaws along with teeth. Tomes invented the first anatomical forceps by considering how teeth and tissues were structured, rather than applying brute force.

His design was so brilliant that it remains largely unchanged today - nearly 200 years of surgeons confirming he got it right the first time.

Modern toothed forceps have three essential parts: The handles give you control and leverage, the pivot point acts as the fulcrum allowing smooth motion, and the jaws with teeth do the actual work, featuring precisely engineered tooth patterns that interlock when closed.

Those teeth aren't random bumps - they're precisely designed projections that create multiple contact points with tissue. When jaws close, these teeth distribute grip pressure evenly while preventing slippage.

Today's toothed forceps are typically made from high-grade stainless steel, though carbon steel and vanadium alloys serve specialized applications. Material choice affects durability and sterilization performance. According to scientific research on surgical grasping instruments, proper material selection significantly impacts instrument longevity and performance.

Toothed Forceps vs Smooth Forceps

Toothed forceps often cause less tissue damage than smooth counterparts, despite having teeth. This seems counterintuitive, but there's solid science behind it.

Toothed forceps work smarter, not harder. Those teeth create multiple anchor points that mechanically lock onto tissue fibers, requiring less squeezing pressure. Smooth forceps rely entirely on friction and compression - like trying to pick up wet soap with oven mitts.

The pressure difference is significant. Smooth forceps require much more compression force to prevent slippage, potentially causing crushing injuries or tissue death. Toothed forceps create small puncture points but often cause less overall damage than the crushing effect of smooth forceps.

| Feature | Toothed Forceps | Smooth Forceps |

|---|---|---|

| Grip Mechanism | Mechanical teeth interlock | Friction and compression |

| Pressure Required | Low | High |

| Slippage Risk | Minimal | Moderate to high |

| Tissue Trauma Type | Small punctures | Crushing/compression |

| Best Applications | Dense tissue, needles, sutures | Delicate tissues, vessels |

Historical Development of Toothed Forceps

Before toothed forceps, dental extractions involved six instrument types: forceps, levers, elevators, pelicans, toothkeys, and screws - most sounding like medieval torture devices.

The pelican and toothkey were particularly notorious. The toothkey used fulcrum and lever action that frequently resulted in broken jaws. Andreas Vesalius made progress in the 1500s by recognizing that molars and canines have different shapes - thinking then!

When Tomes introduced his anatomically designed instruments in 1841, it was like switching from a sledgehammer to a precision screwdriver. His design considered actual tooth and tissue structure, marking the transition from brute force to surgical finesse.

Today's toothed forceps honor Tomes's principles while incorporating modern materials science and manufacturing precision.

Types & Design Variations of Toothed Forceps

Well-equipped surgical suites contain impressive arrays of toothed forceps, each designed for specific tasks and procedures.

Adson forceps are surgical workhorses - delicate 4¾" instruments with fine tips and 1×2 tooth configuration, perfect for precision work. They're versatile enough for superficial tissue manipulation and gentle enough for suture handling.

Rat-tooth forceps feature a single large tooth on one jaw fitting between two opposing teeth, creating incredibly secure grip. This design excels with dense tissues like fascia during closure procedures.

Brown-Adson forceps take the basic Adson design with broader teeth, offering increased surface contact for thicker tissues requiring substantial grip without excessive pressure.

Russian forceps are heavy-duty options with broad, circular serrations providing exceptional grip strength. They're more aggressive, requiring careful technique to avoid tissue damage.

DeBakey forceps feature longitudinal striations instead of traditional teeth, providing grip while minimizing trauma. These were designed specifically for vascular and thoracic procedures where tissue integrity is critical.

Colibri forceps serve ophthalmic microsurgery at just 65mm length with 1×2 patterns and 0.25mm tooth width, optimized for MIGS, cataract surgery, and corneal transplants.

Size ranges span 4¾" to 8", with each serving specific purposes. Shorter instruments excel at delicate work, while longer versions provide deeper access and leverage.

Tooth configurations follow task-matching logic. 1×2 teeth offer minimal trauma with adequate grip, 2×3 teeth provide balanced approach, 3×4 teeth deliver maximum grip for dense tissues, and 4×5 teeth handle the most demanding applications.

Selecting the Right Toothed Forceps

Choosing the right toothed forceps requires understanding both your objectives and working conditions, balancing functional effectiveness with user comfort during long procedures.

Procedure-specific requirements should drive selection. Delicate ophthalmic work needs fine-tip forceps with 1×2 configuration minimizing trauma while providing control. Plastic surgery with skin flaps might require broader teeth and longer handles for optimal leverage.

The 1×2 tooth arrangement has earned reputation as the sweet spot for most applications, providing excellent balance between grip security and tissue preservation while maintaining sufficient holding power.

Ergonomic considerations become crucial during extended procedures. German stainless steel instruments often feature thoughtfully designed handles providing optimal control and reducing hand fatigue.

For insights on related instrument selection, More info about choosing scalpel handles provides valuable complementary guidance.

Materials & Manufacturing

Materials in toothed forceps construction form the foundation of instrument performance, durability, and safety.

German stainless steel represents the gold standard, offering exceptional corrosion resistance, maintaining sharp edges through hundreds of sterilization cycles, and providing necessary strength for reliable performance. German-forged instruments typically include 5-year warranties.

Carbon steel brings exceptional hardness and edge retention, maintaining sharpness longer than stainless steel counterparts but requiring more careful maintenance to prevent corrosion.

Disposable plastic options offer convenience and eliminate cross-contamination risks, particularly valuable where sterilization resources are limited or protocols mandate sterile single-use instruments.

Autoclave compatibility is essential for reusable instruments. Most metal toothed forceps handle standard autoclave sterilization at 134°C for 4 minutes, maintaining temper and sharpness through hundreds of cycles.

Applications & Surgical Technique

Toothed forceps serve critical roles across multiple medical disciplines, each requiring specific techniques and considerations.

Medical Surgery Applications: In general surgery, toothed forceps excel at tissue flap support, enabling perpendicular needle entry during suturing. This capability is valuable for skin closures where precise needle placement is essential for cosmetic outcomes.

Dental Extraction Procedures: Dental applications represent demanding uses for toothed forceps. Instruments must securely grip tooth crowns during extraction while withstanding significant rotational and pulling forces. Different tooth types require specialized forceps designs.

Ophthalmic Microsurgery: Specialized ophthalmic forceps serve in minimally invasive glaucoma surgery (MIGS), cataract procedures, and corneal transplants, demanding extreme precision with 0.25mm tooth widths optimized for microscopic work.

Laboratory and Mortuary Applications: Research applications require toothed forceps with ultrafine tips for manipulating delicate specimens. In mortuary settings, they assist with tissue preparation, suture removal, and restoration procedures.

Using Toothed Forceps in Procedures

Proper technique when using toothed forceps involves several critical considerations affecting both procedural success and tissue preservation.

Grasping Technique: Correct grip involves a pencil hold between thumb and index finger during active use. When not in use, forceps should rest in palmed position to prevent accidental tissue contact.

Tissue Interaction: When grasping fascia or dense tissue, position teeth to distribute pressure across strongest tissue areas. Teeth should penetrate just enough to secure tissue without excessive trauma.

Benefits:

- Reduced slippage during tissue manipulation

- Lower pressure requirements minimize crushing injuries

- Improved precision in delicate procedures

- Improved control during suture placement

Potential Risks:

- Puncture wounds from tooth penetration

- Tissue tearing with excessive force

- Nerve damage in sensitive areas

- Cross-contamination if sterilization fails

Benefits and Potential Risks

The mechanical advantage provided by teeth significantly reduces grip pressure required to secure tissues. This pressure reduction often results in less overall tissue trauma compared to smooth forceps relying on compression alone.

Properly sterilized toothed forceps contribute to infection control by providing secure tissue handling without excessive manipulation. Single-use disposable options eliminate cross-contamination risks entirely.

The primary risk is puncture trauma from teeth themselves. While typically small, these punctures can provide infection entry points if not properly managed. When working near sensitive structures, the secure grip actually reduces nerve damage risk by minimizing repeated tissue manipulation.

Handling, Maintenance & Sterilization

Proper care and maintenance of toothed forceps ensures longevity, reliability, and safety throughout their service life.

Proper Handling: The pencil grip represents optimal holding method during active use, providing maximum control while reducing hand fatigue. When not actively using the instrument, it should rest in palmed position.

Cleaning Protocol: Immediate post-use cleaning is critical:

- Enzymatic Soak: Submerge in enzymatic solution to break down protein deposits

- Manual Cleaning: Use soft brushes to remove debris from tooth crevices

- Ultrasonic Bath: 10-15 minutes with appropriate detergent

- Rinse and Dry: Thorough rinsing followed by complete drying

Sterilization Parameters: Standard autoclave sterilization requires 134°C for 4 minutes (gravity displacement) or 121°C for 15 minutes (pre-vacuum cycle). Chemical sterilants may be used for heat-sensitive materials following manufacturer specifications.

Inspection: Regular inspection should check tooth alignment, hinge function, corrosion, jaw alignment, and handle integrity.

For comprehensive forceps maintenance guidance, More info about forceps types and uses provides detailed information applicable to all forceps types.

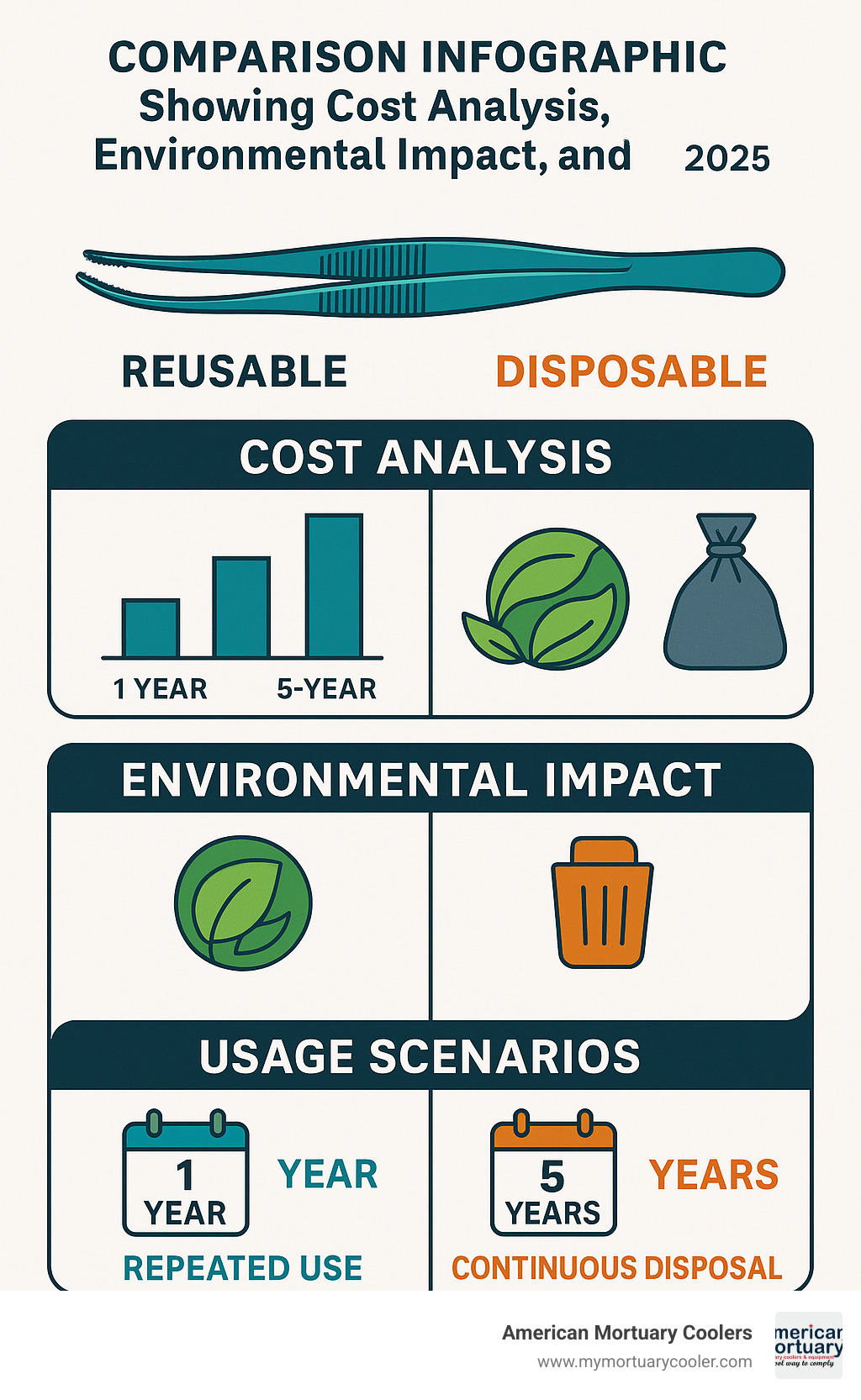

Reusable vs Disposable Options

The choice between reusable and disposable toothed forceps involves cost, environmental impact, and procedural requirements.

Cost Analysis: Reusable German stainless steel forceps represent higher initial investment but provide value through extended use. With proper maintenance, quality instruments withstand hundreds of sterilization cycles. Disposable options have lower upfront costs but accumulate expenses through repeated purchases.

Environmental Considerations: Reusable instruments generally have lower environmental impact over their lifetime despite requiring sterilization energy. Disposable instruments contribute to medical waste but eliminate reprocessing water and energy consumption.

Single-Use Applications: Disposable toothed forceps supplied sterile in boxes of 10 ensure single-use hygiene and eliminate reprocessing requirements, particularly valuable in outpatient settings.

Care Checklist for Longevity

Maintaining toothed forceps in optimal condition requires systematic attention:

Daily Care:

- Complete drying after sterilization

- Inspection for debris in tooth crevices

- Functional testing of hinge mechanism

- Visual inspection for damage

Periodic Maintenance:

- Lubrication of hinge points

- Professional sharpening when needed

- Calibration checks for jaw alignment

Storage: Proper storage in instrument trays with protective covers prevents damage. Store in dry conditions and protect tooth surfaces from contact with other instruments.

Replacement Indicators: Toothed forceps should be replaced when teeth show significant wear, hinge mechanism becomes loose, corrosion affects integrity, or jaw alignment cannot be corrected.

Frequently Asked Questions about Toothed Forceps

How do toothed forceps differ from non-toothed forceps?

The difference between toothed forceps and their smooth counterparts is like comparing a mountain climbing grip to trying to hold onto a slippery rope. It's all about how they grab and hold tissue.

Toothed forceps use mechanical teeth that actually bite into tissue, creating secure anchor points. Think of it like tiny hooks that lock into place. Smooth forceps, on the other hand, have to squeeze harder and rely entirely on friction to keep their grip - kind of like trying to pick up a wet bar of soap.

Here's what's really interesting: even though toothed forceps create small puncture marks where the teeth contact tissue, they often cause less overall damage than smooth forceps. Why? Because smooth forceps have to apply much more pressure to prevent slippage, which can crush tissue or cut off blood flow.

The 1×2 tooth pattern is the sweet spot - one tooth fitting between two opposing teeth. This gives you excellent grip without going overboard on tissue trauma. It's like having just enough bite to do the job without being aggressive about it.

What sizes and tooth configurations are most common?

When it comes to toothed forceps, size definitely matters, and so does the tooth setup. Most surgeons reach for instruments between 4¾" and 8" long, with 5" and 6" being the workhorses of the bunch.

The 4¾" models are perfect for delicate surface work where you need maximum control. Think of them as the precision tools of the forceps world. The 6" and 8" versions come into play when you need to reach deeper or need extra leverage - they're your heavy-duty options.

For tooth configurations, the 1×2 setup is hands-down the most popular choice. It's like the Swiss Army knife of tooth patterns - versatile enough for most jobs while being gentle on tissue. You'll find this configuration in everything from basic medical procedures to specialized ophthalmic work.

When you need more grip strength for tougher tissues, 4×5 tooth configurations step up to the plate. These are for the heavy-lifting situations where you're working with dense fascia or need maximum holding power. The 2×3 pattern sits nicely in the middle ground for moderate applications.

What is the correct way to sterilize toothed forceps?

Getting sterilization right with toothed forceps is crucial - those little teeth can hide troublemakers if you're not thorough. The good news is that once you know the process, it's straightforward.

Start with proper cleaning before you even think about sterilization. Those tooth crevices love to collect debris, so give your forceps an enzymatic soak first. This breaks down proteins and makes everything else easier. Follow up with manual cleaning using soft brushes to get into all those nooks and crannies.

The ultrasonic bath is your friend here - 10 to 15 minutes will shake loose anything stubborn hiding in the teeth. After a thorough rinse and complete drying, you're ready for the main event.

Standard autoclave settings work perfectly: 134°C for 4 minutes if you're using gravity displacement, or 121°C for 15 minutes with pre-vacuum cycles. These temperatures and times ensure everything nasty gets eliminated while keeping your instruments in good shape.

For heat-sensitive materials, chemical sterilants can do the job, but you need to follow the manufacturer's contact times and concentrations exactly. No shortcuts here - patient safety depends on getting this right.

The key to success is making sure your sterilizing agent reaches every surface, especially those tooth areas where bacteria might try to hide. Regular equipment checks and cycle monitoring keep everything running smoothly and give you confidence in your results.

Conclusion

After exploring toothed forceps, it's clear these instruments represent the perfect marriage of ancient wisdom and modern precision. From Egyptian wall carvings to Sir John Tomes's 1841 design, we've witnessed how simple mechanical principles evolved into sophisticated surgical instruments surgeons rely on daily.

What's remarkable about toothed forceps is how they challenge assumptions. Those sharp teeth often cause less tissue damage than smooth counterparts because teeth reduce required grip pressure, minimizing tissue trauma. It's engineering elegance through counterintuitive solutions.

The 1×2 tooth configuration emerges as the sweet spot for most applications - offering grip security without excessive tissue penetration. When dealing with thick fascia or needing maximum holding power, 4×5 configurations have their place despite being more aggressive.

Smart selection comes down to matching tool to job. Consider your tissue type, required reach, and precision needs. Delicate ophthalmic procedures call for something completely different than dental extractions or mortuary preparation work.

Maintenance isn't complicated but requires consistency. Systematic cleaning, proper sterilization at 134°C for 4 minutes, and regular wear inspection keep instruments performing reliably for years. Attention to detail pays dividends in both longevity and patient safety.

For funeral industry professionals, understanding these principles extends beyond knowing tools themselves. Whether selecting instruments for your facility or understanding medical procedures preceding mortuary care, this knowledge adds to professional expertise and helps make better equipment decisions.

At American Mortuary Coolers, we've found clients across Tennessee, Georgia, Illinois, and throughout the contiguous 48 states appreciate partners who understand broader mortuary operations context. While our specialty is crafting custom mortuary coolers and related equipment, comprehensive equipment knowledge helps funeral professionals make informed decisions about all facility needs.

The toothed forceps story demonstrates something beautiful about medical innovation - how centuries of refinement can take basic concepts and polish them into tools that truly serve human needs. As materials science advances and manufacturing becomes more precise, fundamental principles established over centuries continue guiding better instrument development.

Next time you see toothed forceps, appreciate the engineering elegance in those simple interlocking teeth. They represent thousands of years of human ingenuity focused on helping medical professionals do their best work with minimal tissue trauma.

For more information about how our custom mortuary equipment solutions can benefit your operations, and to explore our comprehensive range of custom cooling systems designed specifically for funeral professionals nationwide, visit More info about morgue coolers solutions.