Everything You Need to Know About Hydro Aspirators

Why Hydro Aspirators Are Essential for Modern Funeral Homes

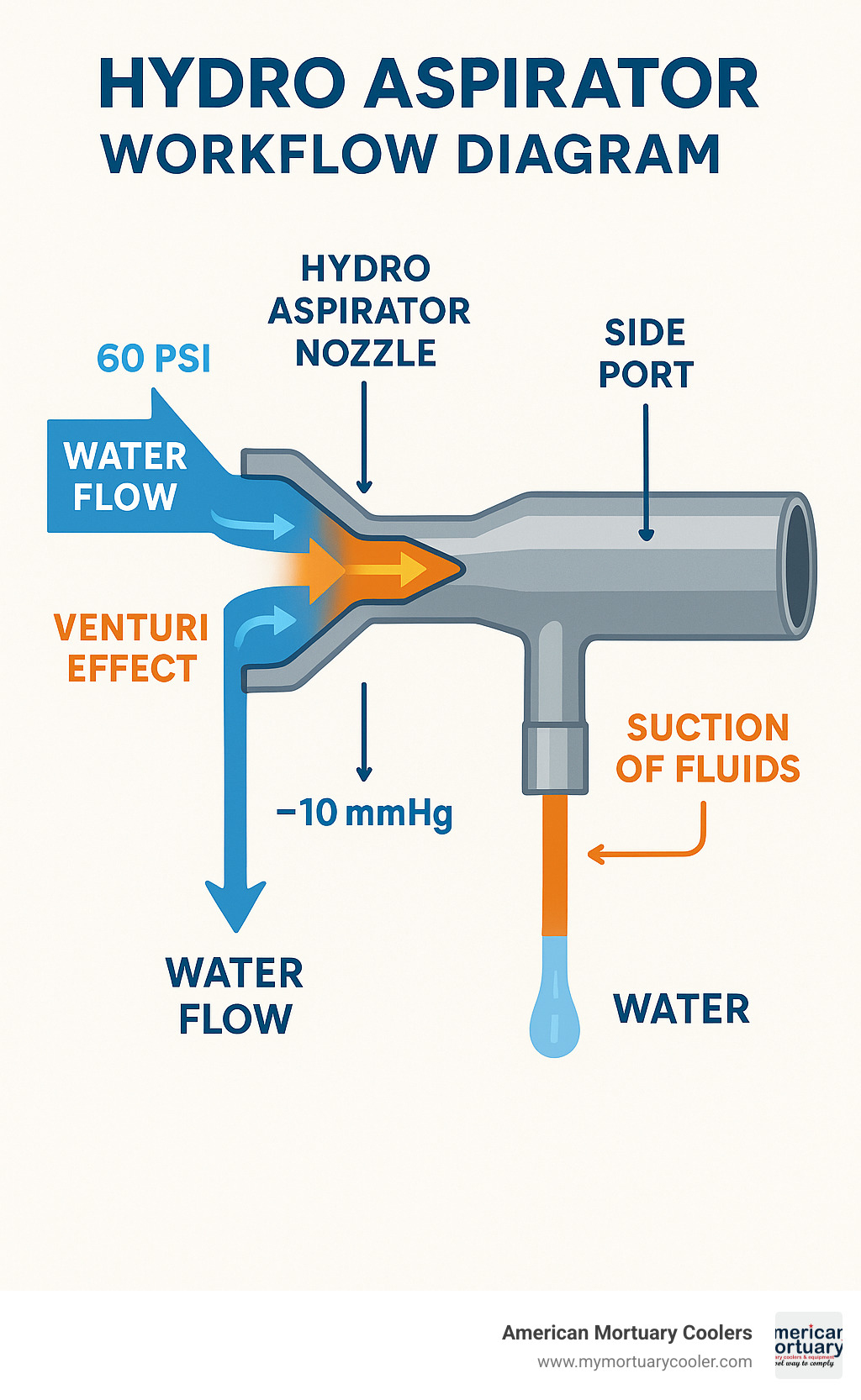

A hydro aspirator is a water-powered vacuum device that creates suction by forcing water through a constricted nozzle, using the Venturi effect to generate negative pressure without electricity or moving parts.

Key Facts About Hydro Aspirators:

- Water Pressure Required: 60 PSI minimum for adequate vacuum

- Vacuum Level: Can achieve down to 10 mmHg (10 torr)

- Water Usage: Approximately 2 gallons per minute during operation

- Primary Uses: Body cavity aspiration, trocar flushing, embalming fluid removal

- Construction: Chrome-plated brass or stainless steel for durability

- Key Feature: Fully disassemblable for cleaning and disinfection

These simple yet effective devices have become standard equipment in funeral homes across America. Water aspirators are an inexpensive and dependable source of moderate vacuum for mortuary procedures, requiring only a reliable water supply to operate.

Unlike electric vacuum pumps, hydro aspirators have no moving parts to maintain or replace. They connect directly to standard faucets and provide consistent suction for embalming procedures. The device works by creating a pressure differential - when water rushes through the narrow opening, it pulls air and fluids through the side port.

However, their simplicity comes with trade-offs. A single unit can consume roughly 50,000 gallons of water per year with moderate use, leading many funeral homes to evaluate electric alternatives for better long-term value.

As specialists at American Mortuary Coolers, we've worked with funeral directors nationwide to optimize prep room equipment for over a decade, helping them choose between hydro aspirator systems and electric alternatives based on their specific operational needs.

What Is a Hydro Aspirator? Working Principles Explained

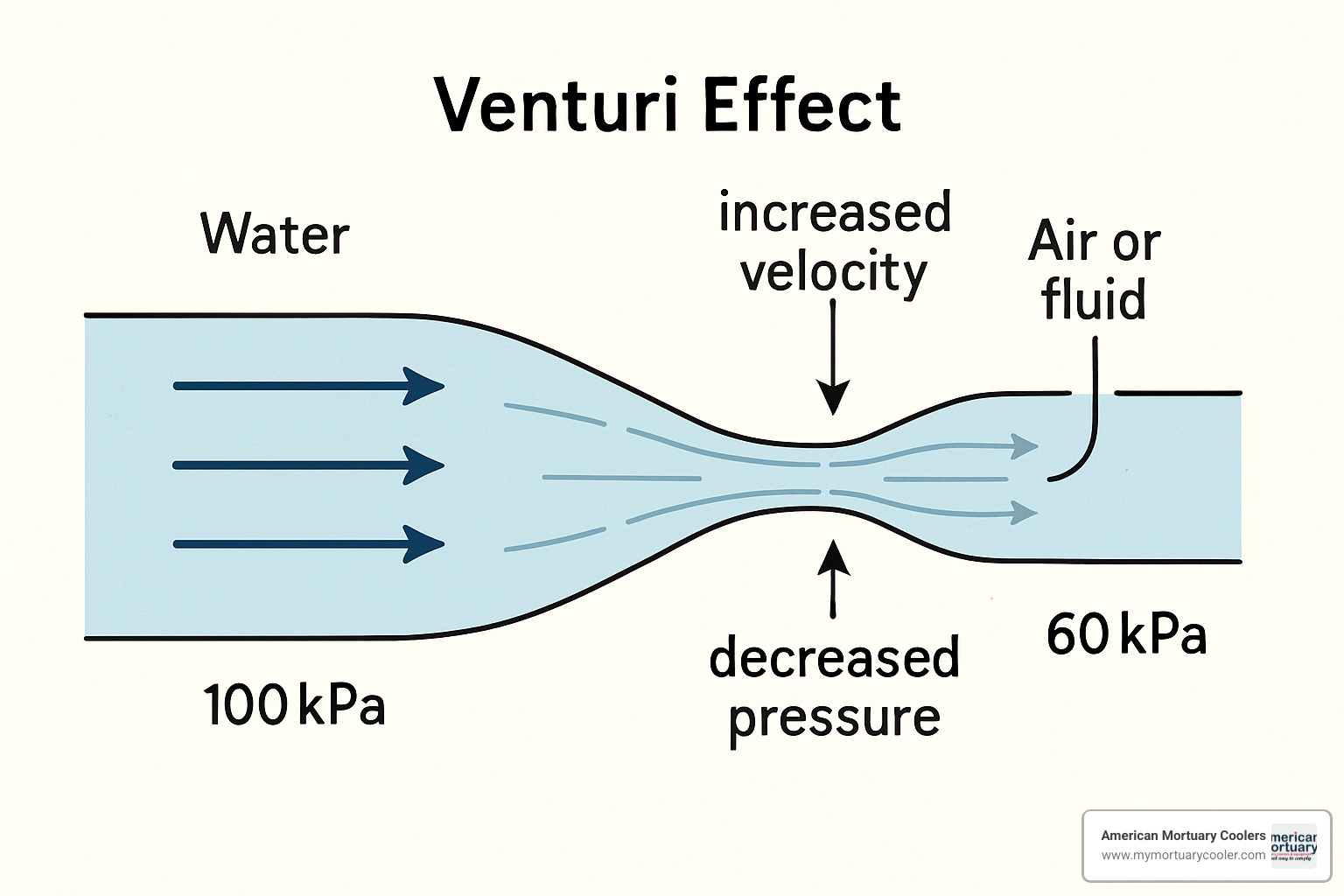

A hydro aspirator works like nature's vacuum cleaner, using simple physics that have remained unchanged for decades. The magic happens when pressurized water rushes through a carefully designed narrow opening, creating dramatic pressure drops through Bernoulli's principle - the same force that helps airplanes fly.

When water enters at normal household pressure (60-85 PSI), it gets squeezed through the narrow nozzle. The faster the water moves, the lower the pressure becomes around it, creating a vacuum zone that pulls air and fluids through the side port.

The beauty lies in its simplicity: no motors, electrical connections, or complex moving parts. Just water, physics, and smart engineering working together.

Hydro Aspirator Fluid Dynamics

Bernoulli's equation tells us that energy in flowing water stays constant but changes forms. When water velocity doubles through the narrow nozzle, pressure drops by four times, creating serious suction power.

The jet nozzle design is critical - too narrow creates turbulent flow, too wide reduces vacuum. Quality units maintain vacuum levels around 10 torr (10 mmHg) while avoiding cavitation, where pressure drops so low that bubbles form and reduce performance.

Consistent water pressure between 60-85 PSI ensures reliable performance. When municipal pressure fluctuates, vacuum performance fluctuates too. Scientific research on vacuum ejector technology continues improving these designs.

Hydro Aspirator Core Components

Every hydro aspirator contains essential parts working together: the main body houses the precision-machined Venturi nozzle, while the side-arm port connects your suction tubing with tapered connections for tight seals.

Most quality units include a vacuum breaker - a safety valve that prevents aspirated materials from being sucked back into water lines when flow stops. Material choices matter significantly: chrome-plated brass offers excellent durability, while stainless steel provides superior chemical resistance.

The best units feature complete disassembly for thorough cleaning and disinfection between cases - essential for maintaining professional standards.

Types, Applications, and Industry Standards

Hydro aspirator devices serve many industries, from research labs to funeral homes. The most common type connects directly to faucets, while portable pump units combine electric pumps with collection bottles for situations requiring water conservation or portability.

Industry standards like ISO 10079 (medical suction), ASTM D2852 (laboratory vacuum), FDA regulations (medical devices), and IEC 60601 (electrical safety) ensure equipment performs reliably and safely.

Laboratory & Medical Use Cases

In research labs, hydro aspirator systems excel at delicate work like cell culture media removal, where gentle suction won't damage fragile cells. Medical applications include dialysis waste removal and specialized procedures requiring moderate vacuum levels.

ISO 7396-1 compliance ensures medical systems meet safety standards with inline filters, overflow protection, and backup systems. Modern units like those from Accuris achieve 15 liters per minute flow rates with vacuum ranging -30 to -750 mbar at just 59.6 dB noise levels.

Mortuary & Industrial Use Cases

For funeral homes, hydro aspirator systems handle cavity aspiration during embalming, removing body fluids while providing consistent suction for trocar flushing. These units maintain 26 inches of vacuum at 60 pounds water pressure, though 15 inches often works better for standard procedures without tissue collapse risk.

Industrial applications include wastewater aeration and powder conveying systems. The appeal remains the same - no moving parts and minimal maintenance. More info about Essential Embalming Equipment shows how these devices fit complete mortuary setups.

Selecting the Right Hydro Aspirator: Specs, Materials & Cost

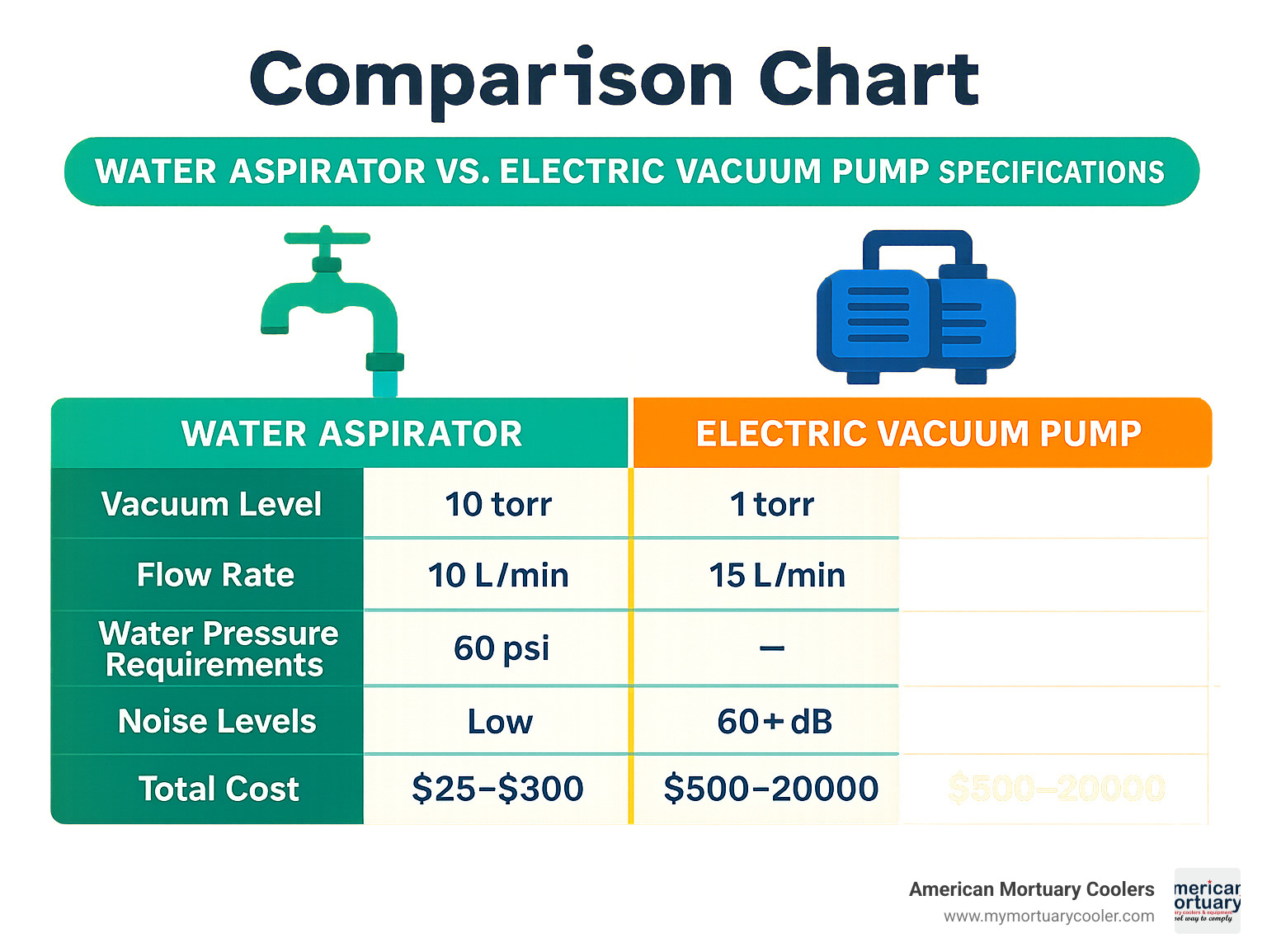

Choosing the right hydro aspirator requires understanding key performance differences. Most units max out around 10 torr vacuum levels versus electric pumps achieving 1 torr or lower. Flow rates range 2-15 liters per minute depending on water pressure and design.

The cost surprise: that innocent-looking water aspirator can consume 50,000 gallons annually with moderate use, costing $200-500 yearly in utilities plus sewer charges. Upfront costs favor water aspirators ($25-300) over electric pumps ($500-2,000), but 10-year analysis often favors electric alternatives.

Key Specifications Checklist

Vacuum level (mmHg) determines suction power - most embalming procedures work fine with 10-15 inches of mercury. Flow rate affects procedure speed but increases water consumption. Inlet/outlet sizes must match existing setups (typically ¾" NPT water, various hose barb sizes).

Chemical compatibility is critical - formaldehyde eats through cheap materials quickly. Chrome-plated brass handles most embalming chemicals well, stainless steel offers ultimate protection. Anti-siphon valves prevent contaminated fluid backflow into water supply.

Budget & ROI Considerations

Basic units start around $25, but professional chrome-plated brass models ($150-300) survive daily mortuary use. That 2 gallons per minute consumption adds up - 2 hours daily equals 50,000 gallons annually, potentially costing $400-1,000 in utilities.

Maintenance tells a different story: hydro aspirator units need virtually no maintenance beyond occasional washer replacement, while electric pumps require oil changes and eventual motor rebuilds.

Scientific research on water consumption shows lifecycle analysis often favors electric pumps in high-use situations, with break-even around year 3-5 depending on utility rates.

Installation, Operation & Maintenance Best Practices

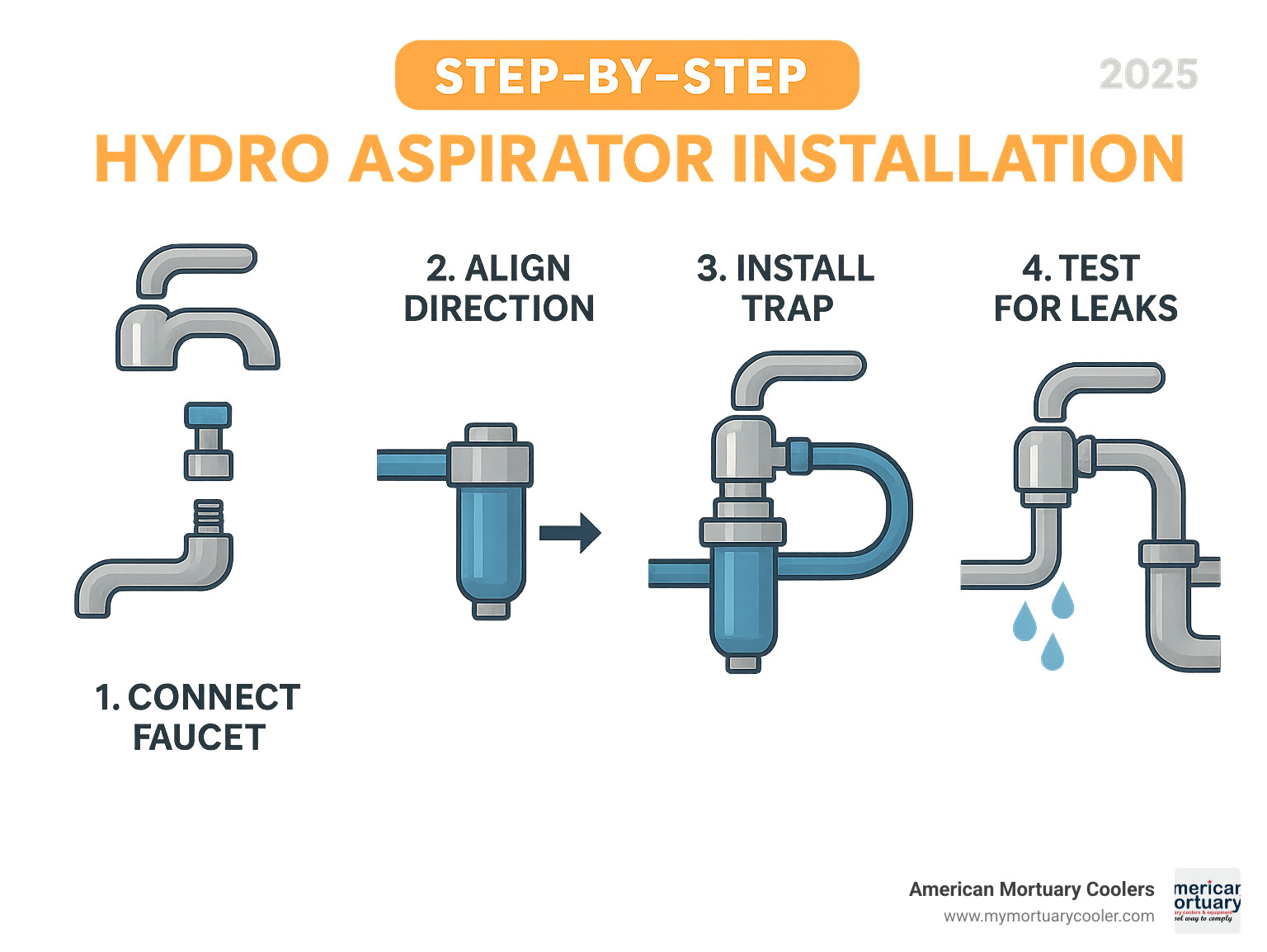

Proper hydro aspirator installation ensures reliable performance and safety. Most units mount directly to existing faucets without major plumbing modifications, but attention to key details prevents ongoing issues with weak suction, water waste, or contamination.

Plumbing layout requires backflow prevention devices to protect municipal water supply - usually required by local codes and essential for safety.

Step-by-Step Setup Guide

Start by shutting off water and checking faucet thread compatibility. Most work with standard threads, but older buildings may need adapters. Mounting height between 6-12 inches above collection area provides comfortable working space with proper drainage.

Flow direction matters tremendously - those arrows on the unit are critical for vacuum generation. Connect your ¾" flex line according to markings or expect poor suction. Install an inline trap between aspirator and collection point to prevent backflow and catch debris.

Position a pressure gauge where operators can see it - consistent 60-85 PSI ensures reliable performance. Test gradually, watching for leaks. Vacuum should develop immediately when water flows.

Routine Maintenance & Troubleshooting

Monthly inspections prevent most problems. Clogs in side-arm ports clear with back-flushing. When vacuum strength drops, check water pressure first, then inspect connections for air leaks and replace worn washers.

The back-flush procedure prevents buildup - many units include control levers for reversing flow direction. Washer replacement represents the most frequent maintenance, usually costing under $5 and taking minutes.

Establish simple maintenance schedules rather than waiting for failures during busy periods. More info about Hydro Aspirator troubleshooting provides detailed guidance for common issues.

Safety, Environmental Impact & Regulatory Compliance

Hydro aspirator safety centers on preventing backflow contamination and protecting operators. Vacuum breakers and backflow prevention devices aren't just good practice - they're often required by plumbing codes to prevent aspirated materials from entering potable water supply.

Personal protective equipment is essential: safety glasses protect against splash hazards, chemical-resistant gloves handle embalming fluids safely. High-velocity water flow creates unexpected turbulence, especially during cleaning operations.

Environmental impact involves significant water consumption (2 gallons per minute) and proper waste disposal. EPA regulations may restrict embalming chemical disposal, requiring separate waste handling.

Water Conservation Strategies

Recirculated chiller systems can reduce consumption by 80-90% but require additional equipment. Foot-pedal shut-off controls cut consumption in half by ensuring water flows only when needed. Timed valves prevent continuous operation from operator distraction.

Vacuum pump retrofits eliminate water consumption entirely while providing stronger, more consistent performance. Initial investment typically pays for itself within 2-3 years through water savings.

Some facilities install drain capture tanks for water reuse in non-potable applications. More info about the embalming process explains how conservation fits broader sustainability initiatives.

Comparing Hydro Aspirators and Electric Vacuum Pumps

Performance gaps are significant: water aspirators max at 10 torr while electric pumps achieve 1 torr or stronger. Consistency represents electric pumps' biggest advantage - municipal pressure fluctuations directly impact aspirator performance, while electric pumps maintain steady performance.

Energy trade-offs: hydro aspirators use zero electricity but waste 50,000 gallons annually. Electric pumps use 100-500 watts but eliminate water waste. Environmental impact depends on local conditions.

Noise favors water aspirators (nearly silent) over electric pumps (59.6 dB average). Maintenance has shifted - newer oil-free electric designs need only filter changes, nearly matching water aspirator simplicity while providing superior performance.

High-use facilities almost always benefit from electric pumps, while occasional-use operations might find water units practical and cost-effective.

Accessories, Replacement Parts & Upgrades

Clear PVC hose transforms basic units into professional systems by letting you see fluid flow, spot air bubbles, and monitor consistency. Trocar adaptors create secure connections between aspirators and various trocar sizes with locking mechanisms preventing accidental disconnections.

Vacuum breakers protect water supply - the Watts backflow preventer represents the gold standard for commercial installations. Clear-view washers let you inspect components without disassembly, while overflow bottles prevent liquid carryover with automatic shutoff valves.

Handheld controllers provide fingertip suction control for delicate procedures. These autoclavable devices work with pipette tips or specialized capillaries. More info about laboratory aspirator accessories shows advanced options for specialized applications.

Having spare parts like washers, seals, and adaptors means you're never stuck waiting for repairs when equipment is needed most.

Frequently Asked Questions about Hydro Aspirators

What water pressure is ideal for a hydro aspirator?

Most hydro aspirator systems work best with 60-85 PSI water pressure, providing about 26 inches of vacuum (though 15 inches suffices for most trocar work). Municipal systems deliver 40-80 PSI with daily fluctuations based on neighborhood demand.

Weak suction often indicates low water pressure - a simple gauge can diagnose this. Areas with chronically low pressure may benefit from booster pumps, though this adds complexity. Pressures above 85 PSI don't improve performance, just create more turbulence.

How do I prevent back-flow contamination into my water line?

Backflow prevention requires multiple safety layers. Quality aspirators include vacuum breakers that automatically let air into the system when water stops, breaking vacuum that could pull contaminants backward.

Most plumbing codes require commercial backflow preventers on supply lines - the Watts backflow preventer is the gold standard. Maintain proper air gaps between discharge and collection vessels, never letting discharge lines get submerged.

Can I retrofit my existing faucet with a hydro aspirator assembly?

Most standard faucets handle hydro aspirator retrofits with ½" or ¾" NPT threading. Success depends on adequate clearance for the assembly and tubing, plus structural support for additional weight and water pressure.

Check water pressure and flow rate at the location first - aspirators need consistent pressure for reliable vacuum generation. Retrofits work well for occasional use, but heavy daily operation benefits from dedicated water lines for better performance.

Conclusion

When it comes to hydro aspirator technology, the funeral industry finds itself at an interesting crossroads. These water-powered workhorses have faithfully served prep rooms for decades, offering the kind of reliable simplicity that busy funeral directors appreciate. Yet as water costs climb and environmental awareness grows, many facilities are weighing their options more carefully than ever before.

The beauty of a hydro aspirator lies in its straightforward approach - connect it to a faucet, turn on the water, and you've got instant suction with no moving parts to break down. For smaller funeral homes or those with occasional aspiration needs, this simplicity remains hard to beat. The initial investment stays minimal, and you're up and running immediately.

However, the numbers tell a compelling story about long-term costs. When you're looking at 50,000 gallons of water consumption annually, those utility bills add up quickly. Many funeral directors find that what seemed like the economical choice initially becomes the expensive option over time.

At American Mortuary Coolers, we've helped countless funeral homes steer these decisions over our years of crafting custom prep-room solutions. Our commitment to providing durable, custom mortuary equipment means we understand that no two funeral homes operate exactly alike. Some need the immediate simplicity of water aspirators, while others benefit from the long-term efficiency of electric vacuum systems.

The sweet spot comes from honestly evaluating your actual usage patterns, local water costs, and performance requirements. A funeral home performing three embalmings weekly faces very different economics than one handling fifteen. Environmental regulations in your area might also tip the scales toward electric alternatives.

What matters most is choosing equipment that supports your professional work without creating unnecessary operational headaches. Whether that's a chrome-plated brass hydro aspirator for reliable simplicity or a modern electric pump for maximum efficiency, the right choice is the one that fits your specific situation.

The technology will continue evolving, but the fundamental need for reliable aspiration equipment remains constant. Understanding these principles and trade-offs ensures you'll make decisions that serve your funeral home well for years to come.

More info about Essential Embalming Equipment provides additional guidance for creating comprehensive prep room setups that support your professional practice while meeting regulatory requirements and operational efficiency goals.