Everything You Need to Know About Mark IV Table 2 Data

Understanding the Mark IV Table 2: Naval Fire Control Innovation

When it comes to early 20th-century naval innovation, few systems transformed maritime warfare quite like the Mark IV Table 2. Developed for the British Royal Navy during the tumultuous years of World War I, this remarkable fire-control system revolutionized how warships engaged targets at sea.

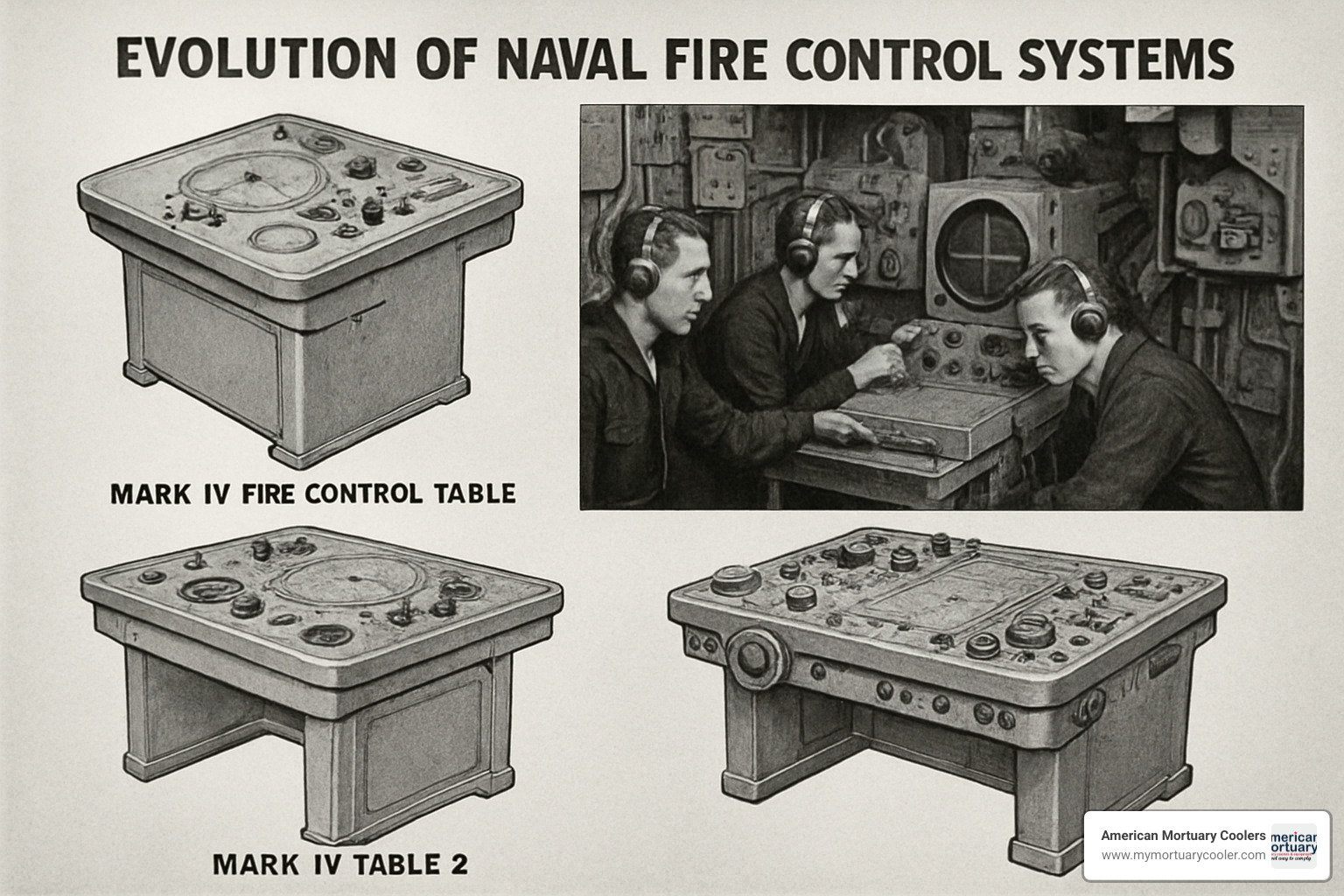

I've always been fascinated by precision equipment that changed history, and the Mark IV Table 2 certainly fits that description. Standing nearly 10 feet wide and over 4.5 feet deep, this imposing calculation table represented the cutting edge of naval technology in its day. It enabled gun crews to track targets moving at various speeds and distances, calculating complex firing solutions that would have been impossible through estimation alone.

What made the Mark IV Table 2 truly special was its combination of electrical automation with manual backup systems. In an era when electrical systems weren't always reliable, this dual approach ensured that even during power failures, the Royal Navy's capital ships could maintain their firing accuracy. The system could track targets from 2,000 yards all the way out to 20,000 yards (later extended to an impressive 28,000 yards), giving British warships a significant tactical advantage.

The Mark IV Table 2 found its home aboard numerous Grand Fleet capital ships, including the flagship HMS Iron Duke. Its development came at a crucial time when naval gunnery was transitioning from relatively close-range engagements to long-distance warfare where precision calculations made all the difference between a hit and a miss.

While my daily work involves creating precision cooling systems for mortuary applications, I can appreciate the engineering brilliance behind the Mark IV Table 2. Both fields require attention to detail, reliability, and performance under pressure – whether preserving dignity in funeral care or protecting a nation's fleet in wartime.

At American Mortuary Coolers, we study historical precision systems like the Mark IV Table 2 to inform our modern mortuary equipment designs. The principles of reliability, redundancy, and precision that made naval fire control systems successful are the same values we bring to our american mortuary equipment. Just as naval officers needed systems they could trust in high-stress situations, funeral professionals need dependable equipment they can count on when serving families during difficult times.

The evolution from manual calculations to precision instruments like the Mark IV Table 2 parallels our industry's journey from basic preservation methods to modern temperature-controlled environments. Even our approach to designing cremation oven systems draws inspiration from how these naval systems balanced technological advancement with practical reliability.

In the sections that follow, we'll dive deeper into the specific components and technical specifications that made the Mark IV Table 2 such a remarkable achievement in naval engineering.

Mark IV Table 2: Definition and Historical Context

The Mark IV Table 2 emerged during a fascinating turning point in naval history, when hitting targets accurately from miles away became the difference between victory and defeat at sea. Developed as part of the innovative Dreyer Fire Control System, this remarkable mechanical computer was the brainchild of Admiral Sir Frederic Charles Dreyer, who created it for the Royal Navy in the early 1910s.

Picture the world before World War I - a naval arms race between Britain and Germany was heating up, with battleships growing increasingly massive and powerful. As gun ranges stretched further than ever before, naval officers could no longer rely on simply eyeballing their shots. Something more sophisticated was desperately needed.

The journey to the Mark IV Table 2 began with the Mark I Dreyer Calculator in 1911. Through careful refinement and innovation, the system evolved until the Mark IV found its home aboard HMS Iron Duke, the Grand Fleet flagship, in mid-August 1914 - just as World War I erupted across Europe. Talk about perfect timing!

This wasn't just another minor upgrade in naval technology. The Mark IV Table 2 fundamentally transformed naval gunnery by bringing together all the complex calculations needed for accurate firing into one centralized system. The latest research from the Dreyer Table Committee reveals just how this approach was for its time.

Why the Mark IV Table 2 Mattered

The Mark IV Table 2 changed everything about naval combat. Before its arrival, each gun turret largely operated on its own, making individual calculations. The new system brought everything together, ensuring all guns worked from the same firing solution - a bit like how modern computer networks sync information.

What made it truly special was its ability to continuously track enemy ships. By plotting course, speed, and range over time, gunners could predict where to aim with unprecedented accuracy. The table even compensated for variables that affect shell trajectory - things like wind direction, ship movement, and even Earth's rotation!

Perhaps most importantly, the Mark IV Table 2 dramatically cut down reaction time. When seconds count in naval combat, being able to quickly calculate an accurate firing solution could mean the difference between landing a critical hit or watching your shells splash harmlessly into the ocean.

By war's end, 19 capital ships in the British fleet boasted either the original Mark IV or its improved Mark IV* variant, giving the Royal Navy a crucial technological edge that helped maintain their naval superiority throughout the conflict.

Terminology 101

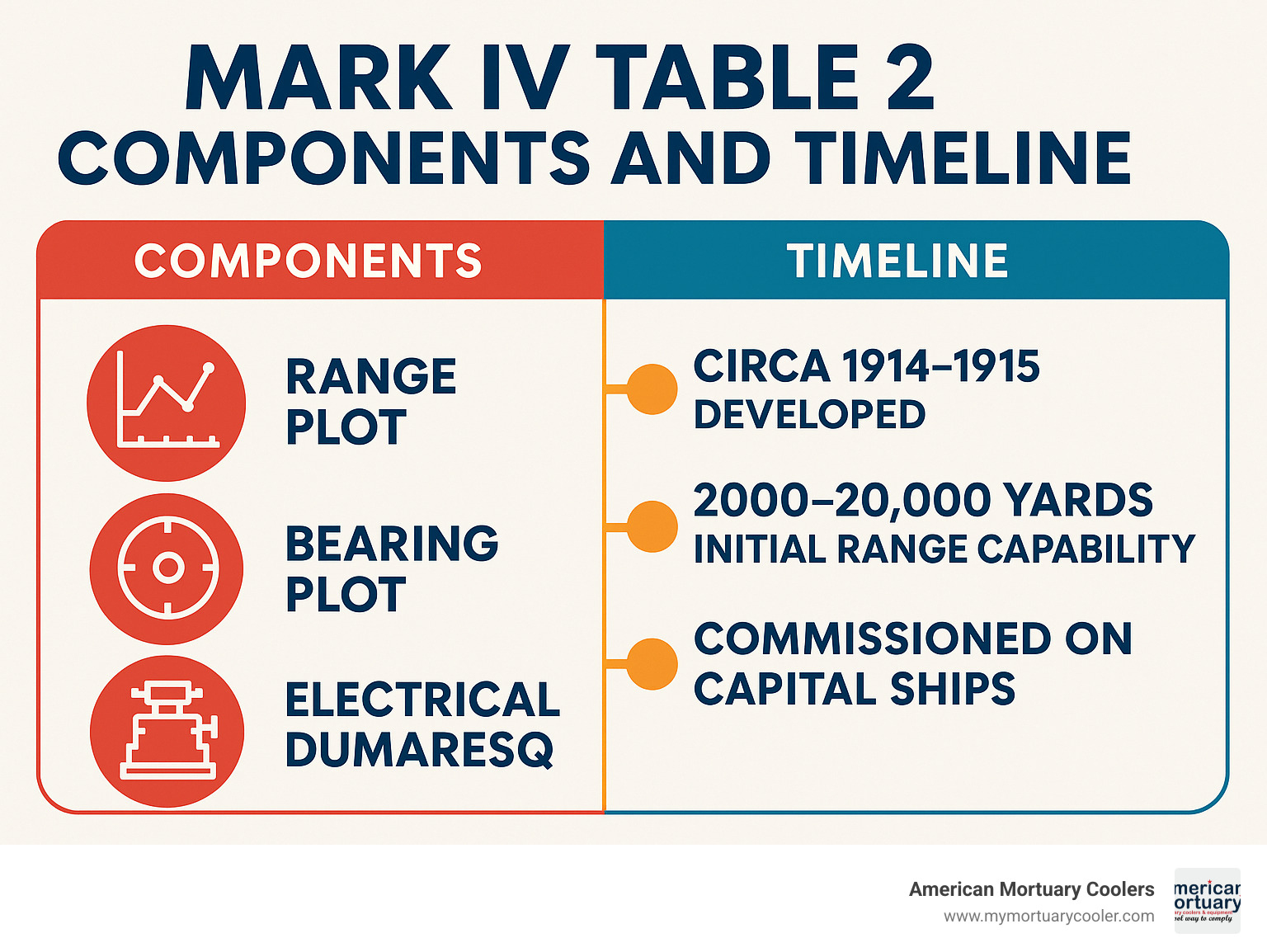

To truly appreciate the Mark IV Table 2, let's break down some key components in plain English:

The Range Plot served as the heart of the system. Think of it as a continuous graph recording the distance to the target over time on a paper roll. Moving at a steady 2 inches per minute with distances marked at 400 yards per inch, this visual representation helped operators spot patterns and predict where the enemy ship would be next.

The Bearing Plot tracked the horizontal angle to the target relative to the ship's heading. Using a clever dual-drum setup, it recorded both the raw bearing and the necessary aim adjustments. This information was vital for knowing how far left or right to point the guns.

The Electrical Dumaresq was perhaps the most innovative piece - essentially an early analog computer that calculated relative motion between ships. The electrical version in the Mark IV Table 2 incorporated gyroscopic heading input and electrical followers, automating what had previously been painstaking manual calculations.

Working alongside these main components were the Rate Grid, which displayed how quickly the range was changing, and the Spotting Corrector, which allowed operators to make adjustments based on where they saw previous shells landing.

Together, these ingeniously designed parts formed a sophisticated engineering marvel that helped shape the outcome of naval warfare during one of history's most significant conflicts. The precision engineering principles pioneered in these systems continue to influence modern technical equipment design - including the calibrated cooling systems we develop at American Mortuary Coolers.

Components and Technical Specifications of Mark IV Table 2

The Mark IV Table 2 was truly a marvel of early 20th-century engineering. If you could step into a World War I battleship's fire control room, you'd immediately notice this imposing device commanding attention with its substantial dimensions—stretching 9 feet 10.5 inches wide by 4 feet 6.5 inches deep. The range grid stood at a height of 3 feet 5 inches, while the dumaresq top reached upward to 5 feet 9 inches, creating quite the presence in the confined spaces of a warship.

Power for this sophisticated machine came from a pair of ¼-horsepower electric motors—one dedicated to the range components and the other handling the deflection mechanisms. The designers, being practical naval men who understood the realities of combat, wisely included hand-crank backups for all electrically driven components. This foresight proved invaluable during power failures or battle damage, allowing the crew to maintain fire control even in the most challenging circumstances.

When first deployed, the Mark IV Table 2 could track targets from 2,000 yards (about a mile) out to an impressive 20,000 yards (over 11 miles). Later modifications in the Mark IV* version extended this range even further to 28,000 yards—nearly 16 miles! The plotting paper (pattern number 3568) moved at a steady 2 inches per minute, with each inch representing 400 yards of distance, giving gunners a clear visual representation of the target's movement over time.

Range Plot Drum

At the heart of the Mark IV Table 2 was its Range Plot—a large drum wrapped with specialized plotting paper where a single red pencil would continuously mark the changing distance to the target. This seemingly simple mechanism was engineering brilliance in action.

The plotting paper itself was 46 inches wide (with 45 inches of usable plotting surface), providing ample space to track a target's range over time. As the drum rotated, the paper created a permanent record of range changes that operators could analyze to spot patterns and predict where the enemy ship might be heading.

Behind this visible component was a precise scaling gear system that ensured the pencil moved in perfect proportion to the calculated range, maintaining the 400 yards per inch scale regardless of the actual distance to the target. The red pencil follower drew a continuous line that told the story of the engagement in real-time—rising when the enemy moved away, falling when they closed distance.

One of the clever improvements in the Mark IV* version was a modest 7.5-inch width increase that allowed for plotting ranges up to 20,000 yards without requiring an extended scale. This small change made a world of difference as naval battles increasingly took place at greater distances throughout World War I.

Bearing Plot Mechanism

Working in perfect harmony with the Range Plot was the Bearing Plot—the component responsible for tracking the horizontal angle to the target. The Mark IV Table 2 featured an innovative dual-drum arrangement that simultaneously recorded raw bearing data and calculated the necessary deflection for accurate firing.

The standard bearing plot by itself would have been useful, but the dual-drum setup took things to another level by providing a more sophisticated analysis of target movement. The scale and deflection drums worked in tandem, translating raw bearing data into actionable targeting information that gunners could use.

Perhaps most impressive was the incorporation of gyro input—direct feeds from the ship's gyroscopic compass that ensured bearing calculations remained accurate regardless of the firing vessel's own movement or heading changes. This was crucial when both ships were moving and maneuvering during battle.

Electrical Dumaresq Unit

If there was a single component that set the Mark IV Table 2 apart from its predecessors, it was the Electrical Dumaresq. Traditional dumaresqs were manual devices that calculated relative motion between ships, but the electrical version automated this process, dramatically improving both speed and accuracy.

The direct gyro-compass feed eliminated the need for manual heading adjustments, while the electrical followers automatically tracked range rate and deflection. This automation freed operators from constant recalculations, allowing them to focus on other aspects of fire control.

The rate grid displayed the change in range over time, helping operators predict where the target would be when shells finally arrived—a critical calculation when shells might take 30+ seconds to reach their destination. Interestingly, the Mark IV Table 2 initially featured irregular markings on its rate grid, which were later replaced with more intuitive linear markings in the Mark IV* version.

The Electrical Dumaresq functioned as an early analog computer, continuously solving complex trigonometric problems that would have been nearly impossible to calculate manually in the heat of battle.

Spotting Corrector & Auxiliary Gear

The Mark IV Table 2 was complemented by several auxiliary components that improved its capabilities:

Nine of the 19 ships equipped with the Mark IV Table 2 received retrofits with a worm-drive spotting corrector linked to the Dreyer Calculator. This ingenious mechanism allowed operators to input corrections based on observed shell splashes, adjusting for systematic errors and improving accuracy with each salvo.

The Brownrigg Keyboard allowed quick entry of range data from multiple sources—optical rangefinders, spotters, and other inputs—creating a more complete picture of the target's position. Meanwhile, the range typewriter automatically recorded all this data, creating a permanent log that could be analyzed later for training and improvement.

These auxiliary systems transformed the Mark IV Table 2 from a mere calculating device into a comprehensive fire control system capable of integrating multiple data sources and adapting to changing battlefield conditions.

At American Mortuary Coolers, we find inspiration in the precision engineering of historical technologies like the Mark IV Table 2. While our stainless steel preparation tables serve a very different purpose, they reflect a similar commitment to thoughtful design, durability, and attention to detail. Just as naval engineers designed backup systems for critical functions, we build our equipment with reliability and functionality as top priorities.

Evolution and Comparative Analysis

The Mark IV Table 2 wasn't created in isolation—it emerged as part of an ongoing evolution in naval fire control systems, building on earlier designs while incorporating new technologies and real-world lessons from combat. To truly appreciate this remarkable system, let's look at how it compared to what came before and after.

The Royal Navy took a practical approach to developing the Dreyer Tables. Rather than starting from scratch with each new version, they made thoughtful improvements to address specific limitations. This incremental approach made a lot of sense—it meant sailors didn't need to completely relearn systems when transferring between ships, and it allowed for faster adoption across the fleet.

Comparing Mark III, mark iv table 2, Mark V

If you were to see these three models side by side, you'd notice a steady growth in size and capability. The Mark IV Table 2 sits squarely in the middle of this evolution, taking what worked from the Mark III while adding innovations that would later be refined in the Mark V.

| Feature | Mark III | Mark IV Table 2 | Mark V |

|---|---|---|---|

| Range Capability | 2,000-15,000 yds | 2,000-20,000 yds (28,000 with extension) | 2,000-30,000 yds |

| Width | Approx. 8 ft | 9 ft 10.5 in | 10 ft 6 in |

| Dumaresq Type | Manual | Electrical with gyro input | Fully electrical with improved automation |

| Backup Systems | Limited | Comprehensive hand-crank fallbacks | Improved redundancy systems |

| Plotting Speed | Manual | 2 in/min paper roll | Improved with multiple plotting options |

| Deployment | Early WWI | Mid-WWI (1914-1918) | Late WWI and post-war |

The Mark III, while impressive for its day, relied heavily on manual calculations and couldn't handle the increasing battle ranges of World War I. The Mark IV Table 2 addressed these shortcomings beautifully by introducing electrical automation and extending the plotting range. These weren't minor tweaks—they dramatically improved both speed and accuracy during combat situations.

What made the Mark IV Table 2 such a leap forward? For starters, its improved electrical integration reduced calculation errors that could mean the difference between a hit and a miss. The direct connection to the ship's gyrocompass provided much more accurate heading data—crucial when calculating where to aim those massive guns.

Those extra inches of width might seem trivial, but they allowed for tracking targets at ranges up to 20,000 yards (and even further with extensions). As naval battles moved to greater distances, this capability became increasingly vital. Perhaps most impressively, the comprehensive hand-crank backup systems meant the table could keep functioning even when power failed or combat damage occurred—a thoughtful feature that saved lives in the heat of battle.

Retrofit Pathways

One of the smartest aspects of the Mark IV Table 2 design was how easily it could be upgraded. Rather than scrapping existing systems—an expensive and time-consuming process—many Mark IV tables were converted to the improved Mark IV* standard through relatively straightforward modifications.

These upgrades typically involved adding about 7.5 inches of width to accommodate better range plotting, replacing the confusing irregular markings on the rate grid with more intuitive linear ones, and adding the worm-drive spotting corrector to selected ships. Nine vessels received this particular improvement, which significantly improved their correction capabilities during combat.

This retrofit approach proved incredibly cost-effective. The Royal Navy could upgrade multiple ships without completely replacing their fire control systems—a huge advantage during wartime when shipyard capacity was stretched thin and vessels needed to remain operational. The standardization across the fleet also meant crews could transfer between ships without extensive retraining, reducing potential errors during critical combat situations.

At American Mortuary Coolers, we appreciate this practical engineering philosophy. Like the naval engineers who designed the Mark IV Table 2, we believe in creating systems that can grow and adapt over time. Our modular approach to mortuary refrigeration allows funeral homes to make incremental improvements without replacing entire systems—saving money while keeping operations running smoothly. It's a practical approach that has stood the test of time, from early 20th-century battleships to today's modern mortuary equipment.

Operational Use, Maintenance, and FAQs

The Mark IV Table 2 wasn't merely an impressive engineering achievement—it was a practical combat system that saw extensive use during World War I. Understanding how it was used, maintained, and troubleshooted provides valuable insights into its real-world effectiveness and the challenges faced by its operators.

The prototype Mark IV Table 2 found its first home aboard HMS Iron Duke, the flagship of the Grand Fleet, in mid-August 1914—just as the world was plunging into war. Talk about perfect timing! This sophisticated system would soon face the ultimate test in the largest naval battles of WWI. By war's end, 19 capital ships proudly housed either the original Mark IV or its slightly improved Mark IV* cousin.

When the smoke cleared at the Battle of Jutland in 1916, the Mark IV Table 2 had faced its most significant trial by fire. While historians still debate who truly "won" that battle, the performance of British fire control systems taught valuable lessons that shaped future improvements.

The Mark IV Table 2 shined in several ways during combat. Its ability to maintain continuous tracking of enemy vessels proved invaluable amid the chaos of battle—imagine trying to hit a moving target from miles away while you're also moving! The system cleverly integrated data from multiple sources, creating a more complete picture than any single rangefinder could provide. Perhaps most impressively, when electrical systems took hits during battle, crews could switch to hand-cranks and keep fighting—a testament to thoughtful design.

That said, Jutland also revealed some growing pains. The system's sophistication meant crew training directly impacted performance—a well-drilled team could work wonders, while inexperienced operators struggled. Like all optical systems of the era, fog or smoke could render the best calculations useless. And even with perfect firing solutions, communicating these complex calculations to multiple gun turrets during the thunder of battle presented its own challenges.

These hard-won insights directly shaped later improvements, including upgrades to the Mark IV* and the eventual design of the Mark V.

Deployment Highlights

The Mark IV Table 2 became a common sight across the Grand Fleet between 1914 and 1919. Following its debut on HMS Iron Duke, the system spread to an impressive roster of battleships and battlecruisers, including HMS Benbow, HMS Emperor of India, HMS Erin, and HMS Marlborough, among others.

This widespread adoption wasn't just about having the latest technology—it reflected the Royal Navy's commitment to standardizing fire control capabilities across the fleet. When crews transferred between ships, they found familiar equipment rather than having to learn entirely new systems. The retrofit of nine ships with the worm-drive spotting corrector showed the Navy's commitment to continuous improvement based on real-world experience.

The Mark IV Table 2 proved remarkably durable, serving well beyond WWI and into the 1920s on many vessels. This longevity speaks volumes about both the effectiveness of its design and the significant investment required to develop its successor. Sometimes the best equipment is the equipment you already know inside and out.

Recent scientific research on naval fire-control has highlighted how these early systems influenced modern computerized targeting, showing a direct evolutionary line from the Mark IV Table 2 to today's sophisticated systems.

Maintenance & Assembly Tips

Keeping the Mark IV Table 2 in fighting shape wasn't a job for the faint-hearted. It required specialized knowledge and regular attention—much like maintaining any precision equipment.

Crews regularly practiced declutching motors during power failure drills. This seemingly simple task—disconnecting electric motors to enable hand-crank operation—had to become second nature. When shells are flying overhead, you don't want to be fumbling with unfamiliar levers!

Hand-crank practice became a regular part of crew training. These drills might have seemed tedious during peacetime, but they ensured sailors could maintain fire control even when electrical systems failed—a not-uncommon occurrence during battle.

The system's numerous mechanical components needed regular lubrication to prevent wear and ensure smooth operation. I can just imagine the maintenance crews with their oil cans, carefully tending to each component like gardeners caring for prized plants.

Paper roll changes required special attention. The range plotting paper (pattern 3568) needed regular replacement, and proper alignment was crucial for accuracy. A millimeter off in the paper alignment could translate to yards of error at the target—potentially the difference between a hit and a miss.

Regular link wear inspection rounded out the maintenance routine. The mechanical linkages throughout the system faced constant motion, especially at sea, making them vulnerable to wear. Regular checks and adjustments kept the system accurate and reliable.

At American Mortuary Coolers, we understand this dedication to maintenance and proper assembly. Though our embalming tables serve a very different purpose, they're designed with similar attention to durability and ease of maintenance, ensuring reliable performance when it matters most.

Frequently Asked Questions about Mark IV Table 2 Data

Q: How many crew members were required to operate the Mark IV Table 2?

A: The Mark IV Table 2 typically relied on a team of 4-6 specialized operators, each handling different aspects of the system. You'd have dedicated people for range plotting, bearing plotting, dumaresq operation, and spotting correction. Beyond this core team, additional personnel communicated the resulting firing solutions to the gun turrets. It was truly a team effort!

Q: How quickly could the Mark IV Table 2 generate a firing solution?

A: With a well-trained crew, the Mark IV Table 2 could deliver an initial firing solution within 30-60 seconds after spotting a target. What's even more impressive, subsequent corrections based on where shells actually landed could be calculated and applied within 15-20 seconds. This rapid adjustment capability gave British gunners a significant advantage in the fast-changing environment of naval combat.

Q: What happened during power failures?

A: The designers of the Mark IV Table 2 clearly understood Murphy's Law! During power failures, operators would smoothly declutch the electric motors and switch to hand-crank operation. Well-practiced crews could make this transition with minimal disruption, though naturally at a somewhat reduced calculation speed. This redundancy proved invaluable during combat when damage to electrical systems was common.

Q: How accurate was the Mark IV Table 2 compared to modern fire control systems?

A: While primitive by today's standards, the Mark IV Table 2 was for its time. Under favorable conditions with skilled operators, it could achieve hit rates of 10-15% at ranges beyond 15,000 yards—quite remarkable when you consider they were hitting moving targets from moving platforms miles away without computers! Modern systems, of course, approach near-perfect accuracy with their sophisticated electronics and computing power.

Q: Could the Mark IV Table 2 account for weather conditions?

A: Yes indeed! Operators could manually input corrections for wind speed and direction, barometric pressure, and other environmental factors affecting shell trajectory. These adjustments relied more on observation and experience than the sophisticated atmospheric modeling used today, but they significantly improved accuracy when properly applied.

Q: How did the Mark IV Table 2 compare to German fire control systems of the same period?

A: The British and German approaches to fire control reflected different philosophies. The Mark IV Table 2 emphasized continuous plotting and trend analysis, while German systems focused on precise initial solutions through superior optical rangefinding. It's a bit like comparing different approaches to cooking—both can produce excellent results in the right hands! Neither system demonstrated decisive superiority during World War I engagements, with crew training and environmental conditions often proving more decisive than the technology itself.

Conclusion

The Mark IV Table 2 represents a fascinating chapter in the evolution of naval warfare technology. As we've explored throughout this article, this sophisticated mechanical computer played a crucial role in enhancing the Royal Navy's gunnery capabilities during World War I, combining innovative engineering with practical combat functionality.

The legacy of the Mark IV Table 2 extends far beyond its direct operational impact. Its design principles—combining automation with manual backups, emphasizing incremental improvement, and prioritizing practical battlefield utility—influenced subsequent generations of fire control systems. Even as electronic computers eventually replaced mechanical calculators, many of the fundamental approaches pioneered in the Dreyer Tables continued to shape naval fire control philosophy.

Think about it—the Mark IV Table 2 was essentially doing complex calculations and data tracking long before digital computers existed. It's a bit like how your smartphone can calculate targeting for a game of Angry Birds, except this was doing it with gears and paper rolls while shells were flying overhead!

The Mark IV Table 2 also demonstrates the importance of adaptability in technical systems. The retrofit pathway from Mark IV to Mark IV* shows how thoughtful design enables cost-effective upgrades. Rather than scrapping entire systems when improvements were needed, the Royal Navy could update existing tables—extending their useful life while incorporating lessons learned in actual combat.

At American Mortuary Coolers, we find inspiration in the precision engineering and practical design of systems like the Mark IV Table 2. While our custom mortuary coolers and preparation tables serve a very different purpose, they reflect a similar commitment to reliability, durability, and thoughtful engineering. Just as the Royal Navy needed dependable fire control systems for critical operations, funeral professionals require reliable equipment for their essential work.

Our team across locations in Johnson City TN, Atlanta GA, Chicago IL, and throughout the United States brings this same attention to detail to every mortuary cooler we create. We understand that, like the naval gunners who relied on the Mark IV Table 2, our customers depend on precision equipment that performs flawlessly when it matters most.

For more information about our custom mortuary solutions designed with this same commitment to excellence, visit our website to learn why we're your one-stop shop for mortuary coolers.

The Mark IV Table 2 may be a historical artifact now, but its legacy lives on in the philosophy that guides precision engineering across many fields—including our own work at American Mortuary Coolers, where we continue to blend innovative design with practical functionality for today's funeral professionals.