Everything You Need to Know About Powered Hands

Why Understanding Powered Hand Technology Matters for Modern Professionals

A powered hand refers to any device that uses electric, pneumatic, or battery power to assist with gripping, lifting, cutting, or manipulating objects - ranging from industrial tools to advanced prosthetics. These devices have revolutionized how we work across industries, from funeral homes using powered hand trucks to move heavy equipment, to stroke survivors regaining independence through myoelectric prosthetics.

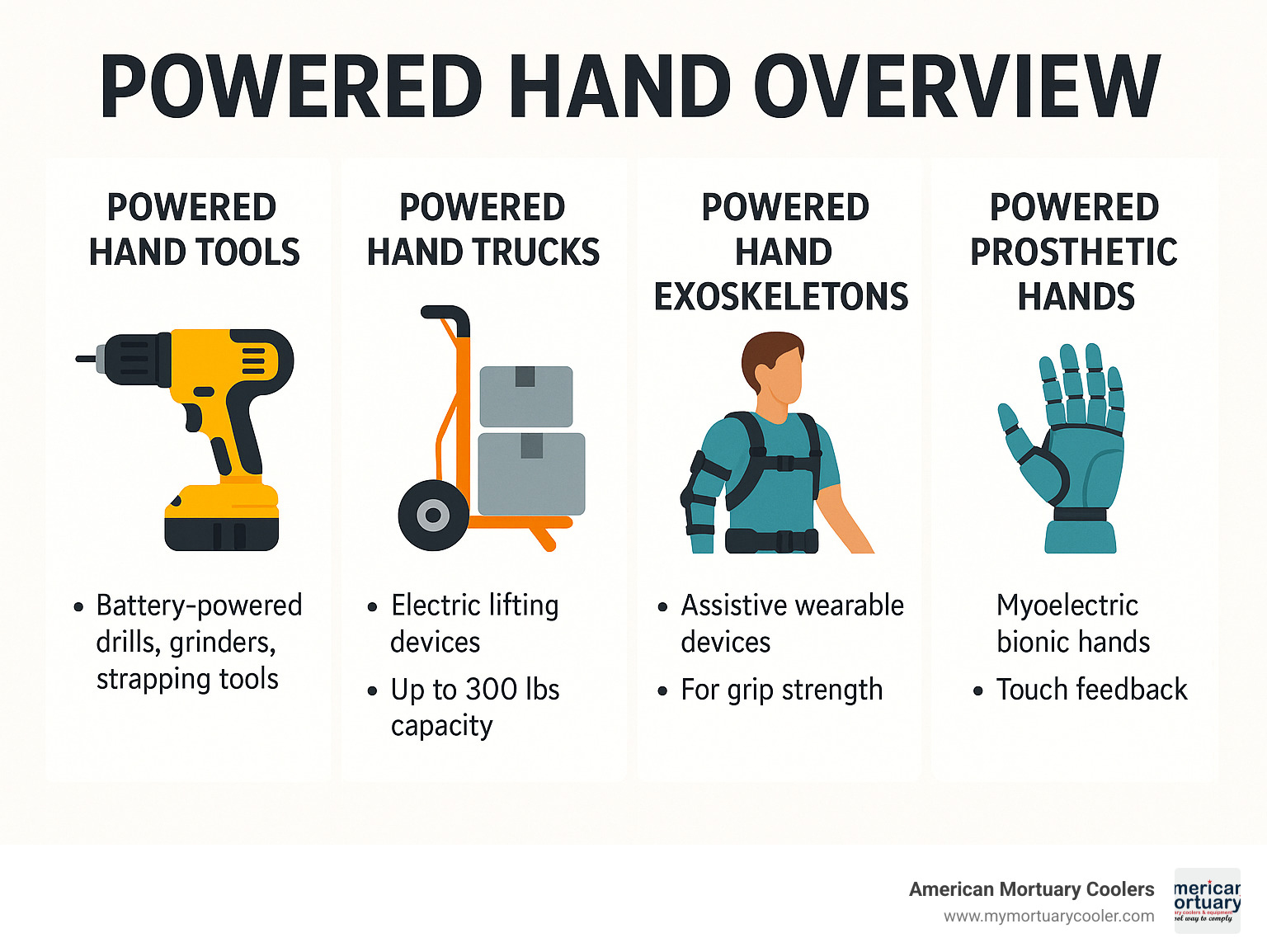

Quick Overview of Powered Hand Categories:

- Powered Hand Tools - Battery-operated drills, grinders, strapping tools

- Powered Hand Trucks - Electric lifting devices (up to 309 lbs capacity)

- Powered Hand Exoskeletons - Wearable assistive devices for grip strength

- Powered Prosthetic Hands - Myoelectric bionic hands with touch feedback

The impact is measurable: powered hand trucks like the Makinex PHT2-140 enable single operators to safely lift 309 pounds through 50 lift cycles per charge, while powered prosthetics help over 80 million stroke survivors worldwide regain hand function. For precision work, these devices should weigh less than 0.5 kg, and for one-handed operation, under 1.4 kg.

Whether you're managing a funeral home that needs reliable equipment for moving heavy items, or exploring assistive technology options, understanding powered hand devices can improve safety, efficiency, and quality of life.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral professionals select durable, powered hand equipment that meets their specific operational needs. My background includes working with funeral homes to integrate reliable powered hand solutions that improve both safety and service quality.

Common powered hand vocab:

Powered Hand 101 – Definitions, Main Types & Core Components

What is a Powered Hand?

Think of a powered hand as your personal strength multiplier. It's any device that takes your natural grip, lifting, or handling abilities and boosts them with electric motors, pneumatic systems, or hydraulic power.

The difference between manual and powered tools is like comparing a bicycle to a motorcycle. A regular hand truck might leave you struggling with a heavy casket, requiring two people for safety. But a powered hand truck? One person can confidently handle loads up to 309 pounds.

Four Key Categories of Powered-Hand Devices

Powered hand tools are probably what you picture first - those trusty battery-operated drills, grinders, and specialized equipment that make tough jobs manageable. Take strapping tools, for example. Instead of wrestling with manual tensioning, these devices can tension, seal, and cut strapping materials in one smooth operation.

Powered hand trucks are game-changers for anyone who moves heavy equipment regularly. The Makinex PHT2-140 uses a robust 12V linear actuator to lift loads from ground level up to 6 feet 2 inches. With about 50 lift cycles per charge, it handles a full day's work without breaking a sweat.

Powered hand exoskeletons sound like science fiction, but they're helping real people today. These wearable devices assist folks with limited grip strength, whether from injury, age, or medical conditions. Research shows most people find devices under 200 grams comfortable for extended use.

Powered prosthetic hands represent the pinnacle of this technology. Modern myoelectric prosthetics like the PSYONIC Ability Hand read muscle signals and translate them into precise movements. With up to 32 programmable grip patterns and haptic feedback, users can feel what they're touching again.

Anatomy & Specs at a Glance

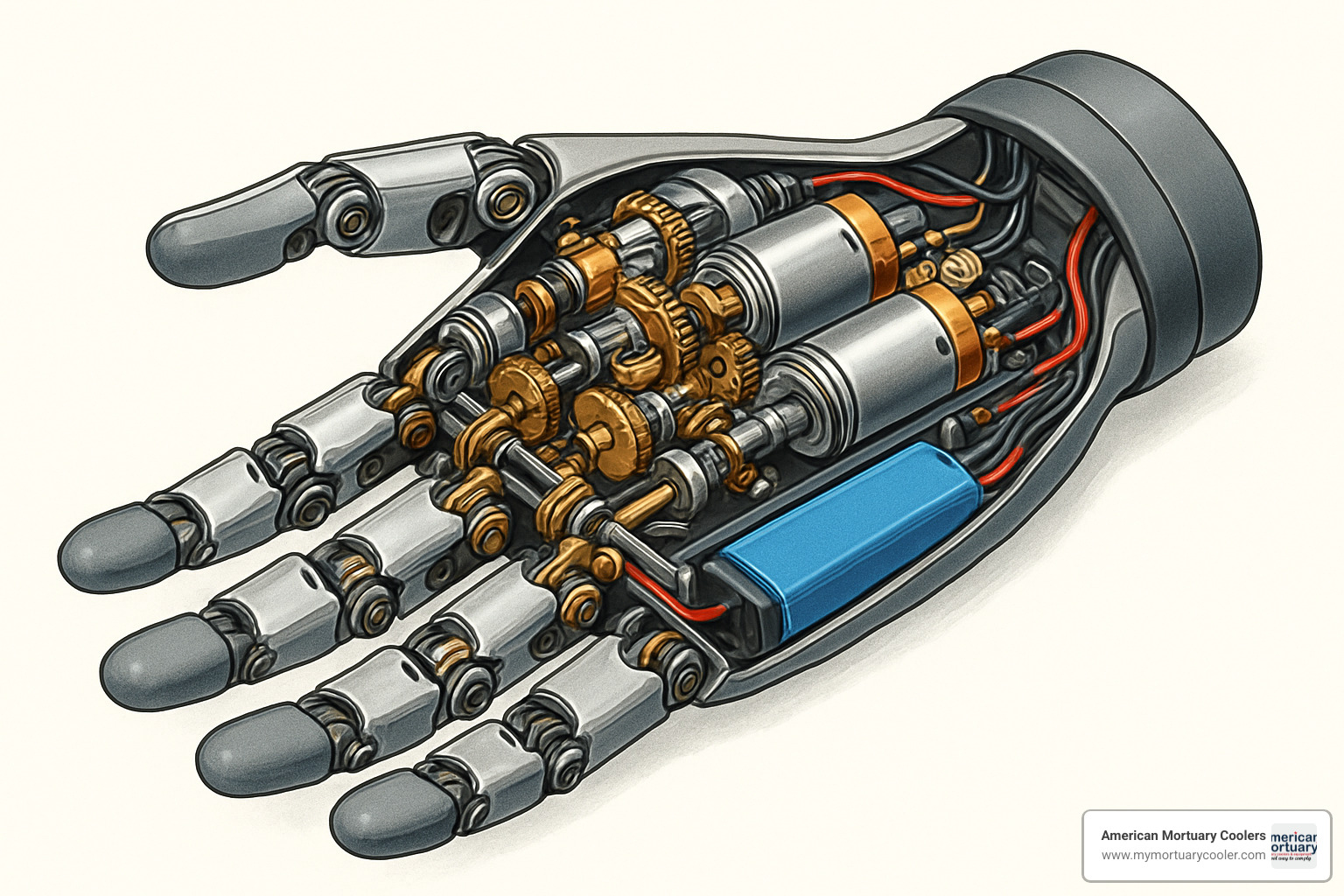

Every powered hand device shares some common DNA. The heart of any system is its actuator - the motor, linear actuator, or pneumatic cylinder that does the heavy lifting. Then there's the control interface, which might be as simple as a trigger or as complex as EMG sensors reading your muscle signals.

Power sources vary dramatically based on the job. Most hand tools run on 7.4V battery systems, while heavy-duty hand trucks need 12V power. The PSYONIC Ability Hand strikes a nice balance with its 7.4V, 2200mAh battery that charges completely in just one hour.

Weight matters more than you might think. For precision work, keep devices under 0.5kg. For one-handed operation, the sweet spot is 1.4kg or less. The Ability Hand prosthetic weighs 490-500 grams, hitting that perfect balance between capability and comfort.

| Feature | Manual Alternative | Powered Hand Device |

|---|---|---|

| Weight Capacity | 50-100 lbs (2 person) | 309 lbs (1 person) |

| Grip Force | 20-30N human max | Up to 66N power grip |

| Battery Life | N/A | 1-8 hours continuous |

| Precision Control | Variable | Programmable settings |

| Safety Features | Basic | Interlocks, auto-shutoff |

How Powered-Hand Devices Work – Mechanisms & Real-World Examples

Understanding how powered hand devices actually work helps you make smarter choices for your facility. Most devices rely on electric motors that convert battery power into rotational or linear motion. These motors connect to linear actuators for lifting applications or gear systems for rotational tools.

Powered-Hand Tools in Industry

Battery-powered strapping tools showcase how integrated motor systems make complex tasks simple. These tools combine tensioning, sealing, and cutting functions into one device using friction sealing technology. No separate buckles or seals needed - just consistent, reliable results every time.

The motor specifications tell the story of their capability. Most heavy-duty units feature 1.5HP motors running at 1800 RPM, drawing about 15.2 amps. That's enough power to handle medium production volumes without breaking a sweat.

Vibration control becomes critical when workers use these tools for extended periods. Quality tools feature vibration-absorbing handles made from cork, rubber, or specialized plastics. The handle should extend at least 10-14cm for proper grip, with trigger strips larger than 2.5cm to distribute force evenly.

For funeral professionals, this matters because consistent performance reduces fatigue during busy periods. Scientific research on ergonomics and vibration confirms that proper tool design significantly reduces workplace injuries.

Powered-Hand Trucks Demystified

The Makinex PHT2-140 represents the gold standard in powered hand truck design. Its 12V 25A linear actuator does the heavy lifting, literally moving loads from 1 foot to over 6 feet in height. At 44kg, it's substantial enough to handle serious work while remaining manageable for one person.

Here's what makes it special: 309 lb capacity with 50 lift cycles per charge. The auto-shutoff feature kicks in after 10 minutes of inactivity, preserving battery life for when you actually need it.

The linear actuator works by converting rotational motor movement into straight-line motion. This eliminates the need for multiple operators or forklift certification. What really impresses funeral directors is how it folds flat for transport.

Powered-Hand Exoskeletons & Prosthetic Hands

Myoelectric control sounds complicated, but it's actually quite neat. EMG sensors detect tiny electrical signals from muscles through the skin. These signals get amplified and processed to control motors with remarkable precision.

Modern systems can distinguish between different muscle activation patterns. The PSYONIC Ability Hand takes this further with embedded fingertip sensors that provide haptic feedback through vibration. Users actually feel what they're touching.

The programming flexibility is impressive - 32 grip patterns available through a mobile app. Power grip delivers 66N of force, while pinch grip provides 9.3N and key grip offers 14N. That covers everything from opening jars to picking up coins.

The pilot study reveals that users prefer 6-8 hours of continuous wear time. This drives the 200g weight target for hand components - heavy enough for functionality, light enough for all-day comfort.

Benefits, Ergonomics & Safety Best Practices for Every Powered Hand User

When you first pick up a powered hand device, you're not just grabbing another tool - you're investing in your long-term health and productivity. These devices deliver measurable benefits that go far beyond simple convenience.

The productivity gains are immediate and substantial. Where manual lifting once required two people to safely move a 100-pound piece of equipment, powered hand trucks now enable single operators to handle loads up to 309 pounds. This isn't just about getting work done faster - it's about reducing workforce strain and minimizing injury risks.

Precision control represents another major advantage. Modern powered hand tools maintain consistent performance regardless of operator fatigue, delivering reliable results on the 50th use just as effectively as the first.

The injury prevention aspect cannot be overstated. Scientific research on ergonomics and vibration shows that proper powered hand tools significantly reduce repetitive strain injuries and vibration-related disorders.

Ergonomic Gold-Standards for Powered-Hand Tools

The magic numbers for powered hand tools aren't arbitrary - they're based on extensive research into human biomechanics. Tools used for precision work should weigh 0.5 kg or less, while one-handed operation devices must stay under 1.4 kg. These limits prevent operator fatigue and maintain accuracy during extended use.

Your wrist position makes all the difference. Neutral wrist positioning - where your hand aligns naturally with your forearm - reduces stress on tendons and nerves. Quality powered hand tools are designed to maintain this natural alignment.

Handle design directly impacts your comfort and safety. Avoid tools with glossy or highly polished handles that increase slip risk. Instead, look for textured surfaces with vibration-absorbing materials that provide better control.

Trigger strips larger than 2.5 cm distribute force over a greater area, reducing muscle fatigue during extended use.

Safety & Maintenance Checklist

Think of your powered hand device maintenance like caring for a reliable friend - a little attention goes a long way. Pre-use inspection should become second nature: check handles, casing, cords, switches, trigger locks, and plugs for any signs of wear or damage before each use.

When you spot a problem, don't gamble with safety. Tag defective tools "Out of Service for Repair" immediately and remove them from service.

Battery care extends your device's life and ensures reliable performance when you need it most. Use only manufacturer-provided batteries and chargers. Replace batteries every 12 months for devices in regular use, and store them in dry areas at room temperature.

Lock-out procedures prevent accidental activation during maintenance. Always unplug devices or remove batteries before changing accessories or performing any maintenance.

Who Benefits Most?

Industrial crews see immediate improvements in both safety and productivity. The physical strain reduction is obvious, but the consistency benefits are equally important.

Logistics staff particularly appreciate powered hand trucks in tight spaces where forklifts are impractical. The ability to operate without special licensing reduces training requirements and improves operational flexibility.

People with disabilities gain life-changing independence through powered assistive devices. Over 80 million stroke survivors globally experience upper limb motor deficits, and nearly 80% can benefit from powered hand devices.

Funeral service professionals find that powered hand equipment transforms daily operations. Moving heavy mortuary coolers, preparation tables, or transport devices becomes safer and more efficient. At American Mortuary Coolers, we've witnessed how the right powered hand equipment can eliminate physical strain while improving service quality.

The connection between proper equipment and professional success isn't coincidental. When your team can work safely and efficiently, they provide better service to families during difficult times. That's why we focus on durable, custom solutions that integrate seamlessly with existing workflows while delivering measurable safety improvements.

Innovations, Leading Brands & the Future of the Powered Hand

Emerging Trends & Breakthroughs

The future of powered hand technology is getting exciting. Soft robotics is changing everything we thought we knew about mechanical hands. Instead of rigid metal fingers that move like tiny robots, these new systems use soft-tendon actuators that flex and move more like actual human hands.

These soft systems finally capture that natural movement while being lighter and less complicated than traditional mechanical designs. Users find them much easier to accept because they feel more like a real hand.

Artificial intelligence integration is another game-changer. Modern devices are getting smart enough to learn your habits and preferences. They can recognize patterns in how you use your powered hand device and adapt accordingly.

Battery technology keeps getting better too. New lightweight lithium-polymer cells last longer while taking up less space. Plus, manufacturers are developing eco-friendly battery chemistries that don't harm the environment as much when they're eventually disposed of.

Key Players & Notable Products

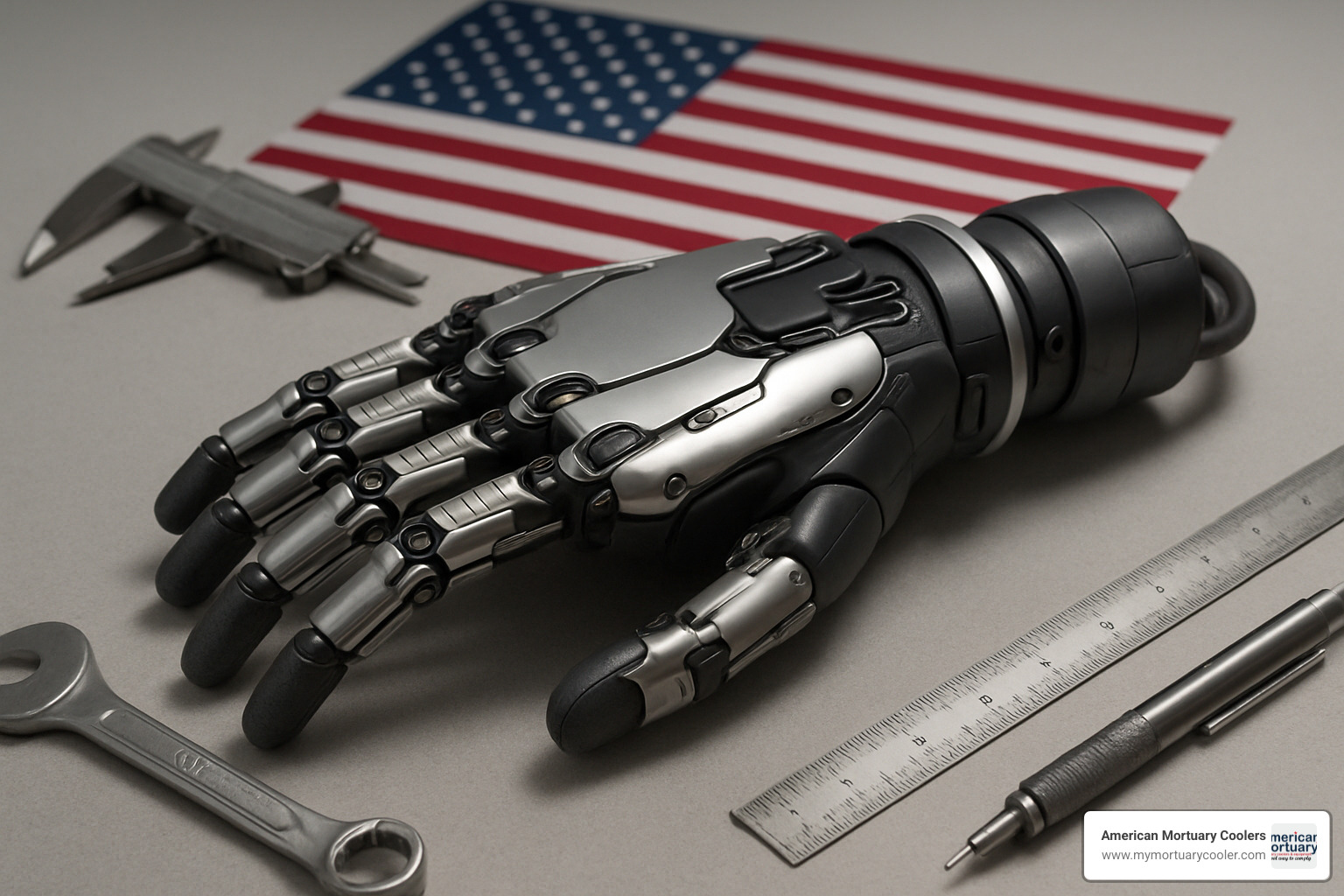

Ottobock has been leading the prosthetic game for years with devices like the Michelangelo hand. Their bebionic series gives users individual finger control - you can literally move each finger separately.

PSYONIC's Ability Hand is shaking up the market by making advanced prosthetics more affordable. At 490-500g, it offers 32 programmable grip patterns with haptic feedback that lets you actually feel what you're touching. The best part? It costs a fraction of what similar devices used to cost.

TRS Inc. takes a different approach with body-powered prosthetic technology. Founded by someone who actually uses these devices, they focus on creating tough, reliable systems for people who need their prosthetics to handle heavy-duty work.

For industrial applications, Makinex dominates with their PHT2-140 powered hand truck. This beast can lift 309 pounds through 50 cycles per charge, and you don't need any special license to operate it.

Powerhand has been making excavator attachments and rotators for over 20 years, particularly for rail infrastructure. Their stuff is built to last in harsh conditions where failure isn't an option.

Market Outlook, Challenges & Opportunities

Despite all this amazing technology, cost barriers remain a real problem. Even with more affordable options like the PSYONIC device, many people still can't afford the powered hand technology that could change their lives.

Insurance reimbursement is another headache. Coverage policies often lag years behind new technology, leaving users stuck with older, less effective devices or paying out of pocket for newer options.

Durability requirements in industrial settings are no joke. These devices need to work perfectly whether it's dusty, wet, hot, cold, or getting banged around.

User adoption varies widely depending on the application. Industrial workers might jump on board quickly if it makes their job easier, but individuals learning to use a prosthetic hand need extensive training and support to get the most benefit.

At American Mortuary Coolers, we've seen how the right powered hand equipment can transform daily operations in funeral homes. The technology keeps improving, and we're excited to help our customers integrate these innovations safely and effectively.

Frequently Asked Questions About Powered Hand Devices

What's the difference between a powered-hand tool and a powered-hand prosthesis?

The difference between these two types of powered hand devices comes down to who uses them and why. Think of it like comparing a race car to an everyday sedan - both have engines, but they're built for completely different purposes.

Powered hand tools are your everyday workhorses designed for people who already have full hand function but want to work smarter, not harder. These are the battery-powered drills, strapping tools, and hand trucks that make industrial jobs easier and safer. They're built tough, often weighing more than prosthetic devices because they prioritize power and durability over comfort.

Powered hand prostheses, on the other hand, are sophisticated medical devices that restore lost abilities. They use myoelectric control to read tiny electrical signals from your muscles and translate them into precise movements. The focus here is on helping someone regain independence - being able to hold a coffee cup, shake hands, or type on a keyboard.

The engineering priorities are completely different too. While a powered drill might weigh several pounds and deliver massive torque, a prosthetic hand like the PSYONIC Ability Hand weighs just 490-500g and focuses on natural movement patterns with 32 programmable grip modes.

How long does a typical powered-hand battery last before recharging or replacement?

Battery life in powered hand devices varies dramatically depending on what you're asking them to do. It's like asking how long a car's gas tank lasts - the answer depends on whether you're cruising down the highway or hauling a trailer up a mountain.

For powered prosthetic hands, expect about 1.5 hours of active use from devices like the PSYONIC Ability Hand, which uses a 2200mAh battery that charges completely in just one hour. That might sound short, but remember these devices are doing incredibly precise work and most users don't need continuous operation throughout the day.

Powered hand tools typically offer 1-8 hours of continuous operation, depending on the workload. Light-duty tasks stretch battery life, while heavy cutting or drilling drains power faster. The Makinex PHT2-140 powered hand truck completes approximately 50 lift cycles per charge - that's about 1.5 hours of steady lifting work, which is plenty for most daily operations.

Here's the practical reality: most powered hand devices include smart features like auto-shutoff after 10 minutes of inactivity to preserve battery life. For replacement schedules, industrial users typically swap batteries annually, while occasional-use devices can go 2-3 years before needing new batteries.

What routine maintenance keeps a powered-hand truck safe and compliant?

Keeping your powered hand truck running safely isn't complicated, but it does require consistency. Think of it like taking care of your car - a little attention regularly prevents big problems later.

Daily checks should become second nature before you power up. Look over the handles, casing, cables, switches, and safety features for any obvious damage. If something looks wrong, tag it "Out of Service" immediately and don't use it until a qualified technician gives it the all-clear. This simple step prevents most accidents and keeps you compliant with safety regulations.

Weekly maintenance involves cleaning debris from moving parts and checking battery connections. Make sure safety features like auto-shutoff and emergency stops work properly. Keep a maintenance log - it's not just good practice, it's often required for insurance and regulatory compliance.

Monthly deep cleaning and lubrication of mechanical components keeps everything moving smoothly and extends the life of your equipment. Store your powered hand truck in a dry area at room temperature (around 70°F), and follow the manufacturer's guidelines if you need to store it for extended periods.

The most important maintenance step is annual professional inspection by qualified technicians. This catches potential problems before they cause equipment failure or safety issues. At American Mortuary Coolers, we've seen how preventive maintenance dramatically reduces downtime and keeps funeral home operations running smoothly. It's much cheaper to maintain equipment properly than to replace it unexpectedly or deal with workplace injuries from equipment failure.

Conclusion

The world of powered hand technology has come a long way from simple battery-operated tools to sophisticated devices that genuinely change lives. Whether you're managing a funeral home in Tennessee, helping stroke survivors regain independence, or simply looking for safer ways to handle heavy equipment, these innovations offer real solutions to everyday challenges.

Think about it: a single operator can now safely lift 309 pounds using a powered hand truck, while advanced prosthetics give users 32 different grip patterns with actual touch feedback. These aren't just impressive numbers - they represent fewer workplace injuries, increased independence, and better quality of life for millions of people.

The key to success with any powered hand device lies in choosing the right tool for your specific needs. That means understanding why precision tools should weigh less than 0.5kg, why your hand truck needs to complete at least 50 lift cycles per charge, and how proper ergonomic design prevents the repetitive strain injuries that plague so many workers.

At American Mortuary Coolers, we've spent years helping funeral professionals across Tennessee, Atlanta, Chicago, and beyond select equipment that actually works for their daily operations. We've seen how the right powered hand equipment doesn't just improve efficiency - it transforms entire workflows while keeping your team safer and more productive.

The future looks incredibly promising. AI-powered control systems are getting smarter, batteries are becoming more eco-friendly, and costs continue dropping as technology matures. What once seemed like science fiction is becoming standard equipment in industries ranging from healthcare to heavy manufacturing.

Powered hand technology represents something bigger than just better tools - it's about empowering people to do more, work safer, and live more independently. Whether you're researching options for your facility or exploring assistive technology for personal use, the right device can make a meaningful difference in your daily life.

For funeral professionals looking to upgrade their equipment, including guidance on comparing scalpel blade options and other essential tools, we're here to help you steer this evolving landscape. Our custom solutions and direct delivery across the contiguous 48 states ensure you get exactly what you need, when you need it.