How to Do Walk-In Cooler Repair, Even if You've Never Tried it Before

Understanding Walk-In Cooler Repair: The Basics

When your walk-in cooler starts acting up, it can feel like a crisis in the making. Trust me, I've been there with countless funeral directors and facility managers watching the temperature slowly climb while their anxiety does the same. But here's the good news – you don't always need to panic or call in expensive emergency services right away.

Walk in cooler repair often begins with some simple troubleshooting steps that even non-technical folks can handle. Whether you're running a funeral home with precious remains, a restaurant with perishable inventory, or a medical facility with temperature-sensitive materials, understanding the basics can save you time, money, and a whole lot of stress.

Most walk-in coolers are built to last 10-15 years with proper care, and I've seen well-maintained units still going strong after 30 years. The secret? Catching small issues before they snowball into major problems that compromise your temperature control and potentially damage what you're storing.

Here's a quick reference guide to common issues you might encounter:

| Problem | Likely Cause | First Steps |

|---|---|---|

| Not cooling properly | Dirty condenser coils | Clean coils every 60-90 days |

| Frost buildup | Defrost cycle issues | Check timer and heaters |

| Water leakage | Clogged drain line | Clear drain with nitrogen |

| Temperature inconsistency | Faulty door seals | Test with paper test (should hold firmly) |

| Strange noises | Fan or compressor issues | Inspect fan blades and connections |

| Stale odor | Refrigerant leak | Call a professional immediately |

I'm from American Mortuary Coolers, where we've helped hundreds of funeral directors and medical facilities across the nation maintain their cooling systems. Through those experiences, I've learned that a little knowledge goes a long way in preventing emergencies and extending the life of your equipment.

In the coming sections, we'll dive deeper into diagnosing problems, performing basic maintenance, and knowing exactly when it's time to call in the professionals. With some simple tools and a bit of know-how, you can handle many walk in cooler repair tasks yourself – saving those service calls for when you truly need them.

When it comes to cooling systems for specialized needs, the stakes are high. Whether you're looking into options for a commercial walk in cooler, specific funeral home refrigeration solutions, or a dedicated walk-in body refrigerator, proper maintenance is the key to reliability when you need it most.

Let's roll up our sleeves and learn how to keep your walk-in cooler running at its best!

Walk-In Cooler Anatomy & Temperature Essentials

Ever wonder what makes your walk-in cooler tick? Before rolling up your sleeves for any walk in cooler repair, it helps to understand the key players in your cooling system's team.

Your walk-in cooler works like a well-orchestrated symphony with four main instruments:

- Evaporator - This indoor component does the heavy lifting, absorbing heat from inside your cooler

- Condenser - Usually perched outside or on top, it's responsible for releasing all that collected heat

- Compressor - Think of this as the beating heart of your system, pressurizing refrigerant to keep everything flowing

- Door gaskets and seals - These unsung heroes maintain temperature integrity and block unwanted air

Don't forget about the drain line – the humble pipe that carries away water during defrost cycles. When this clogs up, it's one of our most common emergency repair calls.

"I've seen perfectly good units brought to their knees by something as simple as a clogged drain," shares Mike, one of our veteran technicians at American Mortuary Coolers. "Getting the defrost cycle right is both a science and an art – it's often what separates a trouble-free system from a headache factory."

Recommended Temperature Ranges

Temperature isn't just a number – it's the whole reason your cooler exists. Here's what you should aim for:

Walk-in coolers: 34°F-40°F (35°F is the sweet spot) Walk-in freezers: -10°F-0°F Ice cream freezers: -20°F to -10°F

The FDA doesn't mess around with food safety, requiring storage below 40°F (4°C). For commercial equipment, the NSF/ANSI Standard 7 provides additional guidelines worth following. Check out the FDA's research on food-safety temperatures for more detailed information.

As one funeral director from our Atlanta location puts it: "Temperature control isn't just about following rules—it's about preserving dignity in our industry. A single degree can dramatically affect preservation quality."

Walk-In Cooler vs Walk-In Freezer Maintenance

While coolers and freezers might seem like cousins, their maintenance needs are more like distant relatives. Here's what makes them different:

Defrost cycles need more attention in freezers, requiring longer and more frequent defrosting than coolers. Your freezer is working harder, so it needs more breaks to shed ice buildup.

Pressure-relief vents are freezer must-haves, equalizing the pressure when you open doors. Without them, you might find yourself wrestling with a door that seems vacuum-sealed shut.

Insulation thickness varies significantly – freezers typically boast 4-5 inches of insulation compared to coolers' 3-4 inches. That extra padding makes a world of difference in efficiency.

Door heaters wrap around freezer door frames to prevent frost buildup and that annoying door-sticking situation we've all experienced.

At American Mortuary Coolers, we've noticed many DIY enthusiasts miss these critical differences when attempting walk in cooler repair, often applying cooler maintenance techniques to freezers or vice versa.

"The biggest mistake I see is treating all refrigeration the same," says our lead technician. "It's like using snow tires in the desert – technically they're still tires, but definitely not what you need for the conditions."

Understanding these fundamentals will help you communicate more effectively with repair professionals and might even save you from making costly maintenance mistakes. When it comes to walk in cooler repair, knowledge isn't just power – it's also money saved and headaches avoided.

Diagnosing Common Problems Before You Call for Walk in Cooler Repair

Let's face it—when your walk-in cooler starts acting up, panic can set in quickly. But before you rush to call a professional service (and open your wallet), there are several simple checks you can perform yourself. Not only might these save you the cost of a service call, but they'll also help you speak the same language as technicians if professional walk in cooler repair becomes necessary.

I've seen it time and again—what looks like a major breakdown often turns out to be something relatively simple. Take that image above, for instance. That heavy frost buildup on an evaporator coil is a telltale sign of defrost issues, something that might not require a complete system overhaul.

When inspecting your walk-in cooler, keep an eye out for these common warning signs: excessive frost buildup on coils often means defrost cycle problems, while water puddles near the cooler typically point to seal failures or a clogged drain line. If you notice a persistent stale odor, especially with rising temperatures, you might be dealing with a refrigerant leak—definitely time to call us. Unusual electrical symptoms like flickering lights or strange buzzing noises shouldn't be ignored either. And if you're seeing a gradual temperature rise over days or weeks, your system could be losing refrigerant or having compressor issues.

I remember a funeral home director in Dallas who called us in a panic, thinking they needed a new compressor. Turns out, they had a loose electrical disconnect that took our technician just five minutes to fix. That quick diagnosis saved them thousands of dollars and prevented unnecessary downtime.

How to Spot Temperature Inconsistencies in Walk in Cooler Repair

Temperature problems are usually the first red flag that walk in cooler repair might be needed. If you suspect inconsistencies, start keeping a simple daily temperature log. Jot down readings at the same times each day—this helps establish patterns and makes troubleshooting much easier.

For more tech-savvy folks, digital temperature sensors can log data over time and even send alerts to your phone. These have saved many of our clients from disaster by catching problems early.

Don't overlook the human factor, either. At a Chicago funeral home, staff members were propping doors open during transfers, causing major temperature swings. No amount of walk in cooler repair would have fixed that—it was simply a matter of adjusting procedures and training.

The humble "paper test" remains one of my favorite diagnostic tools for door seals. Just place a dollar bill or piece of paper in the door gasket and close it. If you can pull it out easily, your gaskets aren't sealing properly and are letting warm air infiltrate your cooler.

Signs of Electrical & Control Failures

Electrical issues can seem intimidating, but many have straightforward solutions. Always start with the basics: check your breaker panel for tripped circuits. Next, inspect the disconnect box near your condenser unit—a loose connection here is surprisingly common.

If your control board display is blank, you might have a blown fuse or power supply issue. Modern digital thermostats like the KE2 models sometimes just need a simple reset or recalibration.

One of our most dedicated technicians once found himself shoveling snow off a pharmaceutical building's condenser unit during a blizzard to maintain critical research refrigeration. It's a vivid reminder that environmental factors can dramatically affect electrical components.

At American Mortuary Coolers, we understand that your cooling system isn't just equipment—your operations and the dignity of those in your care. A little preventative troubleshooting can make all the difference between a minor fix and a major disruption.

Step-by-Step DIY Walk In Cooler Repair Guide

Let's face it – when your walk-in cooler starts acting up, that sinking feeling in your stomach isn't just about the repair bill. It's about potentially lost inventory and disrupted operations. The good news? You can tackle many walk in cooler repair tasks yourself with some basic knowledge and the right tools.

Safety First!

Before you dive into any repair project, safety isn't just a suggestion – it's essential.

Always start by turning off power at the breaker and applying a lock-out tag. This simple step prevents anyone from accidentally restoring power while you're working. Then, double-check with a multimeter to confirm no electricity is flowing to the unit – because peace of mind matters. And please, wear those gloves and eye protection. I've seen too many preventable injuries from folks skipping this basic precaution.

"I once had a client who thought cutting corners on safety procedures would save time," shares our Memphis technician. "Instead, he got a nasty electrical shock that sent him to the ER. Those few extra minutes of safety prep would have saved him a whole lot of trouble."

Essential Tools for DIY Walk In Cooler Repair

You don't need a professional toolkit to handle basic walk in cooler repair, but having these items on hand will make your job much easier:

A good screwdriver set (both Phillips and flathead), an adjustable wrench, and a reliable multimeter form your basic toolkit. Add a coil cleaning brush with appropriate solution, a shop vacuum for debris, a bright flashlight (because coolers can be dark!), an accurate thermometer, and non-acid cleaner for those coils.

Think of these tools as your first line of defense against expensive service calls. When stored near your walk-in unit, they'll be ready when you need them most.

Basic DIY Repair Procedures

Cleaning Condenser Coils

Dirty condenser coils are often the culprit behind a struggling cooling system. The process is straightforward but makes a world of difference:

First, locate your condenser unit (typically outside or on top of the cooler) and turn off power to the unit. Remove any visible debris and dust with a brush or vacuum – you'd be amazed how much can accumulate in just a few months! Apply an appropriate coil cleaner, being careful to never use acid-based cleaners which can damage the coils. Rinse thoroughly, allow everything to dry completely, then restore power and verify the unit is running properly.

"Clean coils can improve efficiency by up to 30%," notes our Nashville operations manager. "It's like giving your system a breath of fresh air."

Replacing Door Gaskets

A leaky door gasket is like leaving money on the table – your cooling system works overtime while precious cold air escapes.

Start by inspecting the current gasket for tears or compression loss. If replacement is needed, carefully remove screws or clips holding the old gasket in place. Take your time cleaning the mounting surface thoroughly – even small debris can prevent a proper seal. Install the new gasket, starting at the corners for the best fit. Finally, test the seal with the paper test: close a piece of paper in the door – it should hold firmly in place with resistance when pulled.

Must-Have Spare Parts

Smart facility managers keep these items on hand for quick walk in cooler repair: Door gaskets, appropriate light bulbs, fuses, fan belts (if your model uses them), and drain line heating tape. Having these ready can mean the difference between a quick fix and days of disruption.

"Neglecting maintenance is a sure recipe for disaster," notes our Columbia, SC technician. "A quick and inexpensive walk in cooler repair can save your equipment from costly larger repairs down the road."

Walk in Cooler Repair: Clearing Drain Line Clogs

If there's one issue that plagues walk-in coolers more than any other, it's those pesky drain line clogs. Left unaddressed, they can lead to water damage, ice buildup, and even structural issues.

Begin by locating the drain line, which typically exits from the evaporator unit inside the cooler. Look for visible clogs that might be removed manually – sometimes it's as simple as clearing debris from the drain pan. For stubborn clogs deeper in the line, a compressed nitrogen blow-out works wonders (this is where having a professional's number handy helps). While you're at it, verify any drain line heaters are functioning correctly, especially crucial in freezer applications. Finally, check that the drain line maintains a proper downward slope of about 1/4 inch per foot – improper installation often causes recurring clogs.

"We had a restaurant in our Los Angeles service area where paint chips and grime had completely clogged a cooler drain," shares our technician. "We had to open the union and blow the drain line with nitrogen. A simple monthly inspection could have prevented this emergency call."

Walk in Cooler Repair: Defrosting an Iced Evaporator

When you open your cooler door and see an evaporator coil that looks like a winter wonderland, it's time for action. An iced-over evaporator is a common reason walk-ins stop cooling effectively.

Most units feature a manual defrost switch or setting – this should be your first step. Once the ice has melted (which may take time, so be patient), check that all defrost heaters are functioning properly. Many system failures stem from a single failed heater element. Next, verify your defrost timer settings – a typical defrost regimen includes four cycles per day at 24 minutes each with a 13-minute drip time, but check your manual for your specific model's recommendations. Lastly, ensure fans restart properly after the defrost cycle completes.

"Ice buildup patterns can tell you a lot about what's wrong," explains our Pittsburgh, PA specialist. "Ice on only one half of the evaporator coil often points to a broken defrost heater, while a specific ice pattern that extends to the compressor might indicate a low refrigerant leak."

At American Mortuary Coolers, we understand that maintaining proper cooling is more than just an operational concern – it's about preserving dignity for families during difficult times. While these DIY tips can help you address common issues, remember we're always just a phone call away when you need professional guidance on your walk in cooler repair needs.

Preventative Maintenance & Cleaning Best Practices

The best walk in cooler repair is the one you never need to make. Preventative maintenance is your first line of defense against costly repairs and system failures.

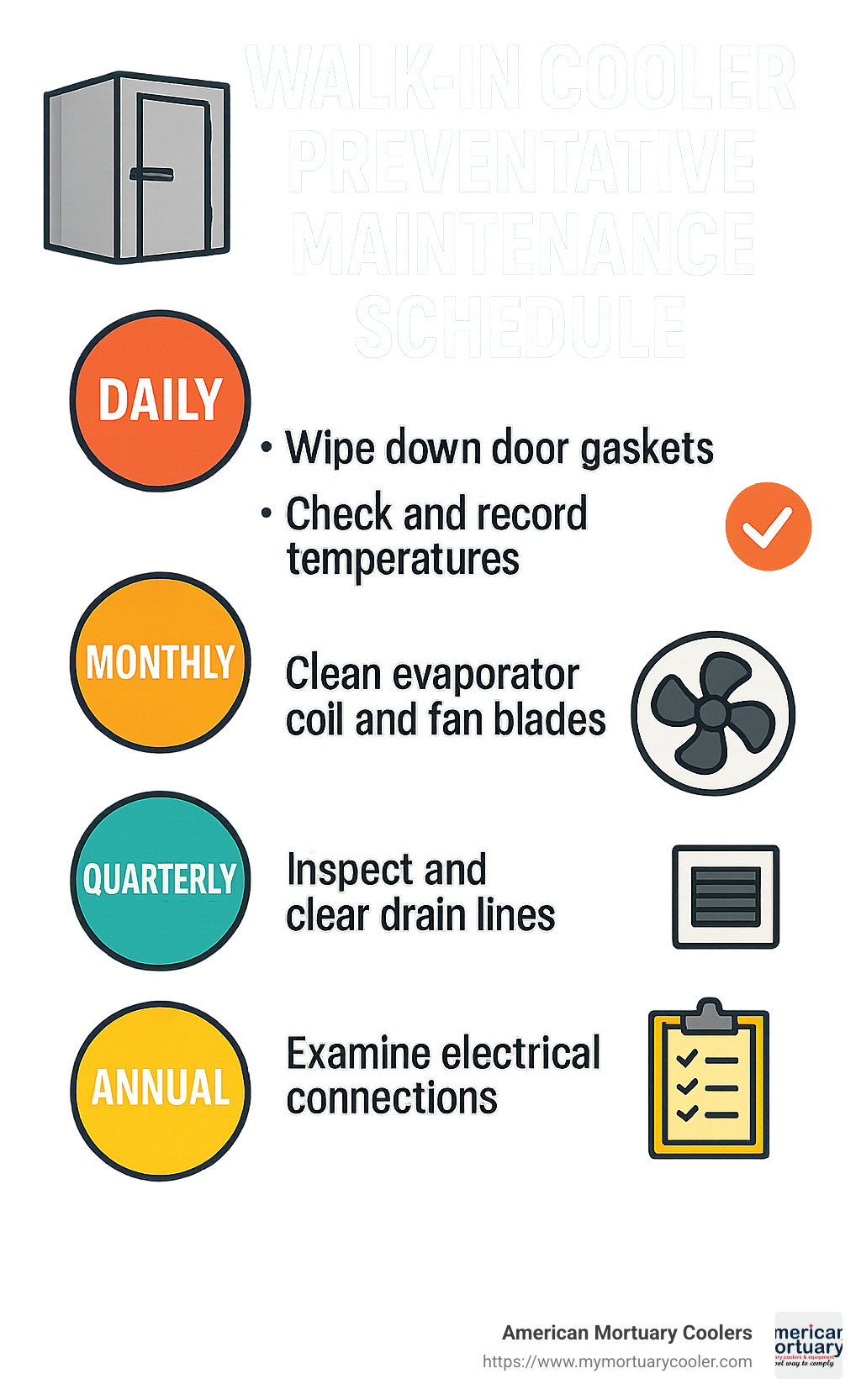

Four-Tier Maintenance Schedule:

Think of your walk-in cooler like a car - a little TLC goes a long way. We've broken down maintenance into manageable chunks that even the busiest facility can handle.

At the daily level, simple habits make a huge difference. Take a moment each day to wipe down those door gaskets with mild soap and water. They're like the weatherstripping on your house - when they fail, everything else suffers. While you're at it, jot down the temperature in a log book (or digital app if you're fancy). This simple practice helps spot trends before they become problems. And please, remind your staff that propping doors open is a cardinal sin in the refrigeration world!

Monthly maintenance is where you'll prevent most emergency walk in cooler repair calls. Power down for a quick interior vacuum to remove debris that can clog drains or damage components. Take a flashlight and inspect the evaporator for ice buildup - even a thin layer can reduce efficiency dramatically. Don't forget to check door hinges and tighten any loose screws. As one of our Memphis clients likes to say, "A quarter-turn today saves a repair call tomorrow."

"We had a funeral home in Nashville who thought their cooler was failing," recalls our service manager. "Turns out, they just needed to tighten their door hinges. The slight gap was letting warm air in, making the compressor work overtime."

When the seasons change, it's time for quarterly maintenance. Those condenser coils need a thorough cleaning - they're the lungs of your system, and when they can't breathe, neither can your cooler. While you're back there, check electrical connections for any signs of corrosion or loosening. A quick peek at the refrigerant sight glass tells you if levels are where they should be. And don't forget to verify your drain line is flowing freely - a simple flush with warm water can prevent flooding issues.

Annual professional maintenance is non-negotiable if you want your investment to last. Our certified technicians do what DIY can't - checking compressor oil levels, calibrating sensors to ensure accurate temperatures, and performing specialized drain line servicing. Many of our clients schedule this around slower business periods to minimize disruption.

Cleaning Condenser & Evaporator Coils Correctly

Dirty coils are the number one reason for unnecessary walk in cooler repair calls. Your condenser coils work like a radiator - when they're clogged with dust and debris, heat can't escape, and your system struggles.

Always start by disconnecting power - safety first! Use only non-acid coil cleaners designed specifically for refrigeration equipment. Harsh chemicals might seem effective, but they can damage the thin aluminum fins that are crucial for heat transfer.

Apply the cleaner and let it sit for the recommended time - usually about 5-10 minutes. This gives it time to break down the grime that's built up. Rinse thoroughly, making sure all cleaner residue is removed. Once everything's dry, check that air flows freely through the coils by holding a tissue near them while the unit runs - it should gently pull toward the coil.

"One of our Louisville clients reduced their energy bill by $200 a month just by implementing quarterly coil cleaning," shares our Kentucky technician. "Their compressor had been running almost constantly because the coils couldn't release heat properly."

Don't forget to check those fan blades while you're at it. Even small buildup can throw them out of balance, causing vibration that wears out bearings prematurely.

Mold & Odor Control Tips

Nothing ruins a cooler's effectiveness (or your reputation) faster than mold and odors. This is especially critical in mortuary applications where dignity and presentation are paramount.

Humidity management is your first defense against mold. While coolers naturally create a humid environment, keeping relative humidity below 60% significantly reduces mold growth. Some of our clients install small dehumidifiers or desiccant packages to help with this.

Surprisingly, paper products are major culprits in mold development. Cardboard boxes absorb moisture like a sponge, creating perfect mold habitats. Consider switching to plastic containers or stainless steel racks when possible. If you must use cardboard, rotate it frequently and never let it sit directly on wet floors.

Door gaskets deserve special attention in your cleaning routine. Their porous material and constant exposure to different temperatures make them mold magnets. A weekly wipe-down with a sanitizing solution (we recommend a mild quaternary ammonium compound) works wonders.

Many of our higher-end clients have finded the benefits of UV lighting installations. These specialized lights, mounted inside the cooler, reduce microbial growth without chemicals. They're particularly popular in our medical and laboratory coolers.

If you're shutting down a cooler for more than a few days, follow our long-term shutdown protocol: clean thoroughly, dry completely, and leave doors slightly open to prevent that stale, musty smell from developing.

"In our humid Southeast region," notes our Florida specialist, "we recommend installing strip curtains behind the main door as an additional barrier against moisture infiltration." These plastic strips allow quick access while minimizing the exchange of outside air. For even better protection, air curtains provide an invisible barrier that can reduce air exchange by up to 80% when doors are opened.

A clean cooler isn't just about preventing walk in cooler repair bills—it's about protecting what's inside and maintaining the professional standards your clients expect.

Repair vs. Replace: Cost, Lifespan & Upgrade Decisions

Every walk-in cooler eventually reaches that crossroads where you need to make a tough decision: invest in another walk in cooler repair or bite the bullet and replace the entire unit. It's not always an easy call to make, especially when you're trying to balance immediate costs against long-term value.

Most walk-in coolers have a lifespan of about 10-15 years, though we've seen plenty reach the 30-year mark with proper care. It's like that reliable old pickup truck that just keeps running with the right maintenance. Your compressor might need replacing every 8-10 years, evaporator fans typically last 10-12 years, while door gaskets need refreshing every 2-3 years. Control boards usually hang in there for 5-7 years before showing their age.

"I remember a funeral home in Memphis that had a cooler running strong after 25 years," shares our service manager. "The owner followed our maintenance schedule religiously—it was practically a family heirloom at that point."

When weighing repair against replacement, the math matters. A compressor replacement running $1,500-$3,000 might seem steep, but at only 15-30% of a new unit's cost, it's usually worth repairing if your cooler is less than 8 years old. Evaporator repairs typically run $800-$1,500, making them worth fixing in most cases. Door assemblies are almost always worth repairing at $600-$1,200, and control systems at $500-$1,500 make sense to fix unless you're looking to upgrade anyway.

The warning sign comes when you're facing multiple component failures totaling $3,000 or more—roughly 30% of a new unit's cost. That's when replacement starts looking like the smarter long-term investment.

"When we assess a unit for potential replacement at American Mortuary Coolers, we look beyond just the immediate repair cost," explains our Midwest Region specialist. "Energy efficiency gains from newer units can often justify replacement even when repair seems cheaper in the short term."

Choosing Location & Type of New Condensing Unit

If you're leaning toward replacement, where you put your condensing unit matters almost as much as which one you choose.

Top-mount units save valuable floor space and stay cleaner in dusty environments, but heat rises, potentially making them work harder. Plus, your maintenance team needs to be comfortable working on ladders.

Side-mount condensers offer easier access for maintenance and work well in spaces with low ceilings. The downside? They take up wall space and might get bumped in busy areas.

Remote condensing units move heat and noise outside your workspace, which can significantly extend compressor life. While installation costs more upfront due to longer refrigerant lines, the peace and quiet—not to mention energy savings—often justify the investment.

One of our Phoenix clients opted for a remote unit after struggling with an overheating compressor. "In Arizona summers, moving that heat source outside made a world of difference," they told us. "Our electric bill dropped enough that we noticed it the very first month."

When Replacement Beats Walk-In Cooler Repair

There are four clear signals that it's time to replace rather than repair:

First, if your system uses R-22 or other phased-out refrigerants, you're fighting a losing battle as supplies dwindle and prices soar. Refrigerant bans aren't just regulatory headaches—they're warnings that your system is becoming obsolete.

Second, when you spot structural panel rot or insulation damage, you're looking at fundamental issues that repairs can't fully address. It's like finding termites in your home's foundation.

Third, when your repair estimate exceeds 50% of a new unit's price, replacement usually makes more financial sense. We call this the "half-price rule" when advising our clients.

Finally, don't overlook energy efficiency gains. Modern units can reduce your energy consumption by 30-40%, which means a new cooler might essentially help pay for itself over time.

"We had a funeral home in our Rocky Mountain Region facing R-22 refrigerant issues," shares our technician. "Rather than pay escalating costs for a diminishing supply of refrigerant, they opted for a new system that paid for itself in three years through energy savings alone."

The decision doesn't always come down to pure dollars and cents. Sometimes it's about peace of mind, knowing you won't face another emergency walk in cooler repair during a critical time. For funeral homes especially, reliability isn't just convenient—maintaining dignity and trust.

Emergency Breakdowns & Safety Protocols

Even with diligent maintenance, emergency walk in cooler repair situations can still catch you off guard. Having a solid plan in place isn't just good business—it can save thousands in product loss and prevent major disruptions.

I remember getting a frantic call from a funeral director in Nashville whose walk-in cooler suddenly failed during a summer heatwave. The panic in his voice was real—but because he had our emergency contact information ready, we were able to dispatch a refrigerated trailer within hours while our repair team addressed the compressor failure.

Your emergency response toolkit should include a 24/7 hotline to your repair service (keep this number posted where everyone can find it). You'll also want a clear product relocation plan that outlines exactly where contents will go if your primary system fails. For funeral homes and medical facilities where temperature control is absolutely critical, having a backup trailer option on speed dial can be a lifesaver—literally.

"During a major power outage in Dallas, we delivered a 5'x10' refrigerated trailer within 4 hours to a client whose primary system had failed," shares our Southwest Region manager. "This stopgap measure prevented a potentially devastating loss while repairs were completed."

Don't forget to consider generator use for power outages—even a small portable generator can keep critical components running during a short outage. And always maintain clear lockout/tagout procedures for safety during emergency repairs. We've seen too many close calls when panicked staff try DIY fixes without proper safety protocols.

First 5 Minutes After a Cooler Failure

What you do in those first moments after finding a cooler problem can dramatically affect the outcome. Here's your five-minute emergency plan:

Keep doors closed as much as humanly possible. Every time you open that door, precious cold air escapes. I had a client in Memphis who kept checking if his cooler was "getting colder yet" every ten minutes—and each check accelerated the warming.

Record the temperature and time you finded the issue. This information helps technicians understand how quickly the system is warming and provides crucial documentation for insurance claims if product loss occurs.

Check your breaker panel first—you'd be surprised how often the solution is this simple. Our Atlanta technician reports that roughly 15% of emergency calls are resolved by resetting a tripped breaker.

Call professional help immediately, even if you think you might resolve the issue yourself. Getting in the queue for service could mean the difference between same-day repair and waiting until tomorrow.

Prepare alternative cooling options like ice, dry ice, or temporary refrigeration. For funeral homes, this might mean contacting neighboring facilities for temporary space.

"The first thing many people do is exactly wrong," notes our Chicago technician. "They open the door repeatedly to check if it's getting colder, which only accelerates temperature rise. Keep it closed except for essential access."

Selecting a Qualified Walk-In Cooler Repair Service

Not all repair services are created equal, and choosing the right partner for your walk in cooler repair needs can make all the difference in an emergency.

Look for CFESA membership (Commercial Food Equipment Service Association), which certifies qualified technicians who meet rigorous training standards. Factory-authorized technicians have specific training on your equipment brand and often have better access to parts.

Always clarify warranty coverage before repairs begin—the last thing you need during a crisis is surprise costs. Modern service providers often offer remote monitoring capabilities that can detect problems before they become emergencies and provide data-driven insights during troubleshooting.

The best repair companies offer specific response time guarantees—at American Mortuary Coolers, we promise arrival within 4 hours for emergency situations across our service areas. When temperature control is critical to your operation, every minute counts.

"When I complained about a previous repair, Sherman reached out several times to make things right and he did. The customer service is outstanding," shared a funeral director from our Southeast Region.

One final tip that's saved our clients countless headaches: establish a relationship with your repair service before you have an emergency. A technician who's familiar with your equipment will respond more effectively when crisis strikes. At American Mortuary Coolers, we offer preventative maintenance programs specifically designed to keep emergency calls to a minimum while ensuring we know your system inside and out if problems do arise.

For immediate emergency assistance with your walk-in cooler, you can always reach our 24/7 emergency line or explore refrigerated trailer rental options as a temporary solution.

Frequently Asked Questions about Walk-In Cooler Repair

What are the most common issues that need walk in cooler repair?

After helping hundreds of funeral homes with their refrigeration needs, we've seen certain problems pop up time and again. At American Mortuary Coolers, we find that dirty condenser coils top the list of culprits. When these coils get caked with dust and debris, your system works overtime trying to maintain temperature—kind of like trying to breathe through a clogged straw.

Door gasket failures are another frequent headache. These rubber seals might seem insignificant, but they're actually your first line of defense against warm air sneaking in.

"Damaged door seals force cold units to run continuously to maintain temperature," explains our Pacific Region specialist. "It's a simple fix that's often overlooked until the compressor fails from overwork."

Other common troublemakers include drain line clogs (which lead to those mysterious puddles on your floor), defrost timer malfunctions (causing those impressive ice sculptures on your evaporator coils), control board failures in newer digital systems, and the slow-developing but potentially expensive refrigerant leaks.

How long should a walk-in cooler last with proper maintenance?

Think of your walk-in cooler like a quality vehicle—treat it right, and it'll serve you faithfully for decades. The average walk-in provides about 10-15 years of reliable service, but we've seen well-maintained units still going strong after 20-30+ years.

"We have clients in our Pittsburgh, PA service area still using coolers we installed over 25 years ago," notes our Northeast Region director. "The difference is always in the maintenance commitment."

Several factors influence your cooler's lifespan. The quality of the initial installation sets the foundation—a properly installed system simply runs better from day one. Regular preventative maintenance (not just fixing things when they break) keeps small issues from becoming major failures. Your operating environment matters too—excessive heat, humidity, or dust will challenge even the best systems. Finally, how you use the cooler daily (frequency of door openings, loading practices) impacts longevity.

Can I perform walk in cooler repair myself without voiding warranty?

This question comes up in almost every conversation with our customers, and the answer isn't black and white. Generally speaking, basic maintenance like cleaning coils, checking temperatures, and inspecting door seals won't void your warranty—in fact, manufacturers expect you to handle these tasks.

Where things get tricky is with component replacement. Swapping out a door gasket might be fine, but replacing a compressor yourself will likely void warranty coverage. Refrigerant handling requires EPA certification for good reason—it's both environmentally regulated and potentially dangerous. And electrical modifications should only be attempted by qualified electricians, both for warranty and safety reasons.

"Always check your warranty documentation before attempting repairs," advises our Johnson City, TN specialist. "Some manufacturers are more lenient about DIY maintenance than others."

When in doubt, it's better to make a phone call than risk voiding your warranty. At American Mortuary Coolers, we're always happy to advise whether a particular walk in cooler repair task is DIY-appropriate or best left to the professionals. After all, your cooler is too important to your operation to take unnecessary chances.

Conclusion & Next Steps

Let's face it—your walk-in cooler is one of the most critical pieces of equipment in your facility. Whether you're preserving food or caring for the deceased, a functioning cooler isn't just important—it's essential.

Throughout this guide, we've explored the ins and outs of walk in cooler repair, from basic troubleshooting to knowing when it's time to call in the professionals. The good news? With the right approach, you can significantly extend the life of your equipment while reducing those panic-inducing emergency situations.

At American Mortuary Coolers, we've seen how a little preventative care goes a tremendously long way. The funeral directors who sleep best at night are those who've acceptd a proactive maintenance mindset rather than a reactive one.

Remember these five golden rules of walk-in cooler care:

Know your system intimately. Understanding the basic components—from evaporators to drain lines—helps you speak the language of refrigeration when talking to technicians. It's like knowing the basics of your car before heading to the mechanic.

Make maintenance a habit, not an event. Those weekly wipe-downs and monthly coil checks might seem tedious, but they're your first line of defense against major failures. As one of our long-time clients likes to say, "A clean coil today keeps the repair tech away."

Always prioritize safety. We can't stress this enough—proper lockout/tagout procedures aren't just recommendations, they're potentially life-saving practices. The few extra minutes they take are always worth it.

Document everything. Your temperature logs and maintenance records aren't just paperwork—they're valuable diagnostic tools. When patterns emerge, they often tell a story about what's happening inside your system.

Have a backup plan ready. Even with perfect maintenance, emergencies happen. Knowing exactly what steps to take in those first critical minutes after finding a cooler failure can make all the difference between a minor inconvenience and a major crisis.

For those in the funeral industry, we understand that your refrigeration needs go beyond mere equipment concerns. Proper cooling is fundamentally about preserving dignity and providing peace of mind to families during their most difficult moments. That's why we've dedicated ourselves to not just selling coolers, but to supporting the entire lifecycle of your refrigeration system.

From our headquarters in Johnson City, Tennessee, to our service connections across all 48 contiguous states, American Mortuary Coolers is committed to providing the specialized knowledge and support that funeral professionals need. Whether you're in the market for a new system or looking to maximize the life of your current one, we're here to help.

Need more information about walk-in cooler features and pricing? We've got you covered with our complete guide to walk-in cooler features and prices.

The most expensive walk in cooler repair is almost always the one you could have prevented. With the right knowledge and a bit of regular attention, your refrigeration system can provide reliable, efficient service for many years to come—keeping both your operating costs and your stress levels firmly under control.