In Depth Guide to Walk-In Freezer Options

Why Walk-In Freezers Are Essential for Modern Cold Storage

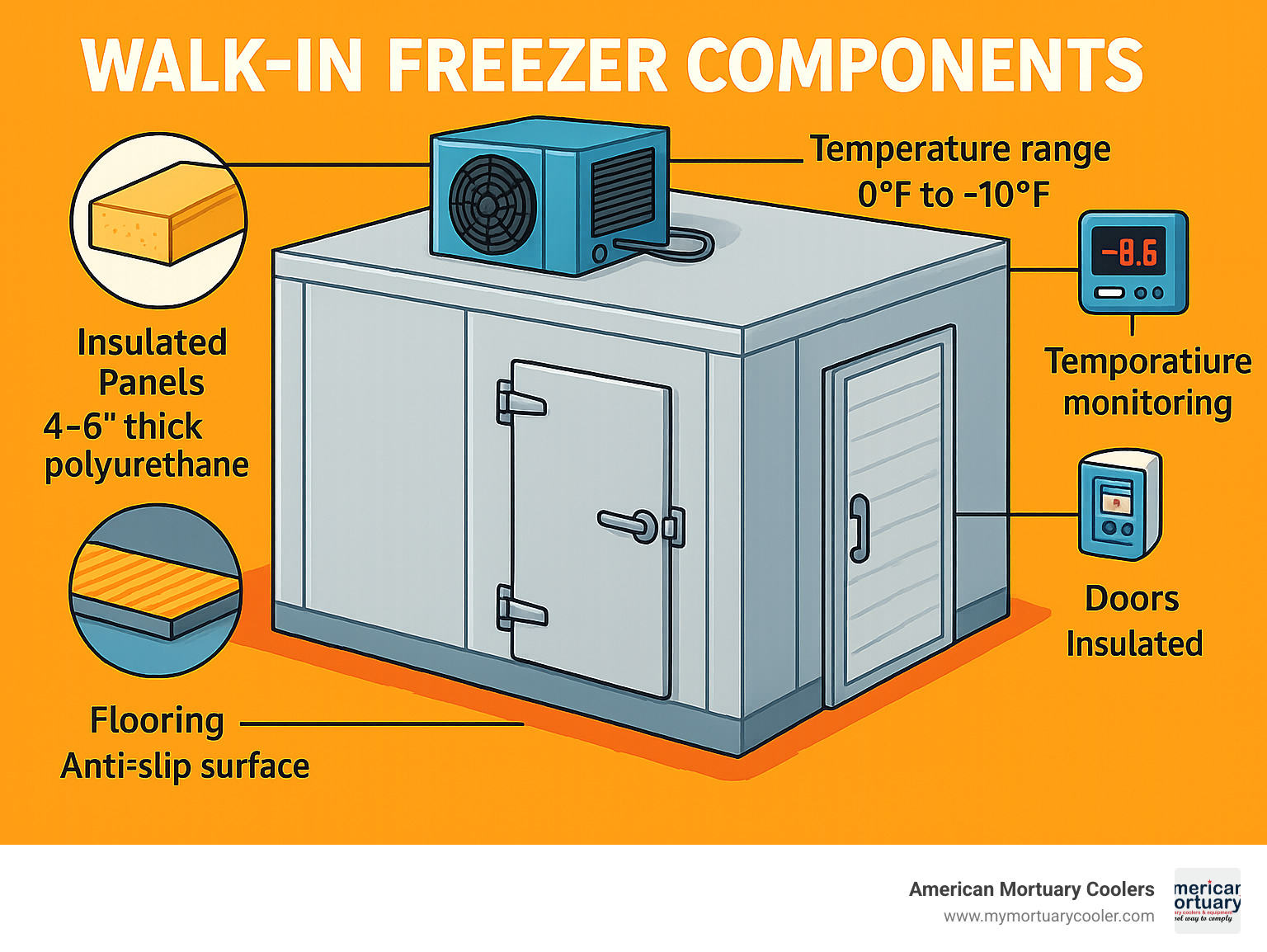

A walkin freezer is a large, walk-in refrigerated room designed to store bulk quantities of frozen goods at temperatures between 0°F and -10°F. Here's what you need to know:

Key Features:

- Temperature Range: 0°F to -10°F (some go as low as -50°F)

- Insulation: R-32 minimum with 4-6 inch thick polyurethane panels

- Storage Capacity: Approximately 28 lbs of food per cubic foot

- Lifespan: Average 15 years with proper maintenance

- Cost: $15,000-$25,000 plus $2,500-$4,000 installation

Common Applications:

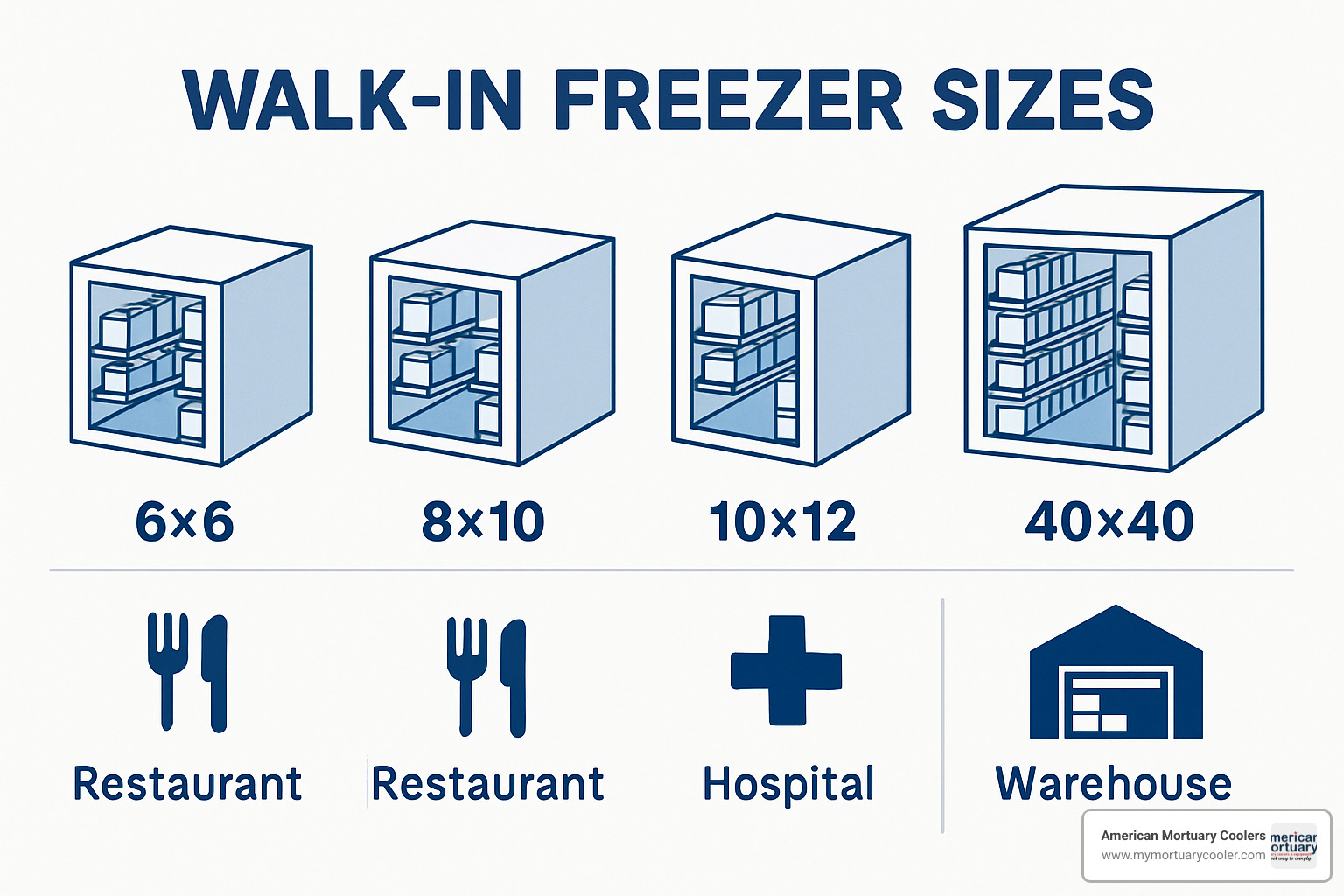

- Restaurants and foodservice operations

- Grocery stores and convenience stores

- Healthcare facilities and mortuaries

- Floral shops and breweries

Walk-in freezers serve as the backbone of cold storage across countless industries. Whether you're preserving food inventory, storing medical supplies, or maintaining mortuary operations, these units convert empty space into reliable, temperature-controlled storage areas.

The choice between different walkin freezer options can significantly impact your operational efficiency and long-term costs. With proper sizing and maintenance, these units deliver consistent performance while meeting strict safety and energy efficiency standards.

As American Mortuary Coolers, we've spent years helping facilities nationwide select and install walk-in freezer systems that meet their specific needs. Our experience with mortuary and commercial cold storage has shown us how critical proper walkin freezer selection is for maintaining product integrity and regulatory compliance.

Walkin Freezer Fundamentals

A walkin freezer might look similar to a walk-in cooler from the outside, but these units are built for an entirely different job. Understanding these differences will help you make the right choice for your operation.

What is a walkin freezer?

Think of a walkin freezer as your walk-in cooler's much tougher cousin. While coolers keep things chilled around 35°F, freezers work much harder to maintain temperatures between 0°F and -10°F. Some specialized units can even reach -50°F when you need extreme cold storage.

The magic happens in the construction details. Walkin freezers use thicker insulation - typically 5 to 6 inches of polyurethane panels with R-32 insulation values. That's significantly more than the 4-inch R-25 panels you'll find in coolers. This extra insulation isn't just for show - it's essential for maintaining those sub-zero temperatures efficiently.

These units also feature improved vapor barriers that prevent moisture from sneaking in and compromising the insulation. The refrigeration systems are specially designed to handle the greater temperature differential between inside and outside conditions.

Walkin freezers typically run four defrost cycles per day to prevent ice buildup on the coils. This automatic defrosting keeps your unit running efficiently without you having to think about it.

Key industries & applications

Walkin freezers show up in more places than you might expect. Restaurants and foodservice operations rely on them for bulk ingredient storage and handling seasonal inventory spikes.

Healthcare facilities use these units for storing vaccines, medications, and biological samples that require precise temperature control. Some pharmaceutical applications need those ultra-low temperatures below -20°F.

In the mortuary industry - our specialty here at American Mortuary Coolers - we typically work with units operating at 35°F to 40°F. These applications require special features like improved insulation and discrete exterior finishes that blend with the facility's professional appearance.

Specialty businesses have found creative uses too. Floral shops store cut flowers at 33°F to 35°F to extend their life, breweries use them for fermentation control, and game lockers need the robust construction for meat processing operations.

Standard vs custom sizes

Walkin freezer sizing starts small and goes really, really big. Compact units like 6×6×7'7" or 8×10×8'2" work perfectly for small operations with limited space. These are popular with smaller restaurants or specialty shops.

Medium commercial sizes include 10×12, 12×16, and 8×14 configurations, giving you anywhere from 81 to 200 square feet of storage space. These hit the sweet spot for many businesses.

When you need serious storage capacity, industrial-scale units can reach 40×40×20'5" - that's 1,600 square feet of freezer space with multiple access doors and openings wide enough for forklifts.

Container units offer a portable solution using modified 20-foot and 40-foot shipping containers. These can handle temperature ranges from -30°F to 86°F, making them incredibly versatile.

The beauty of modern walkin freezers lies in their modular construction. Most units use interlocking panels that allow for custom dimensions while maintaining structural integrity and insulation performance.

Sizing & Capacity Planning

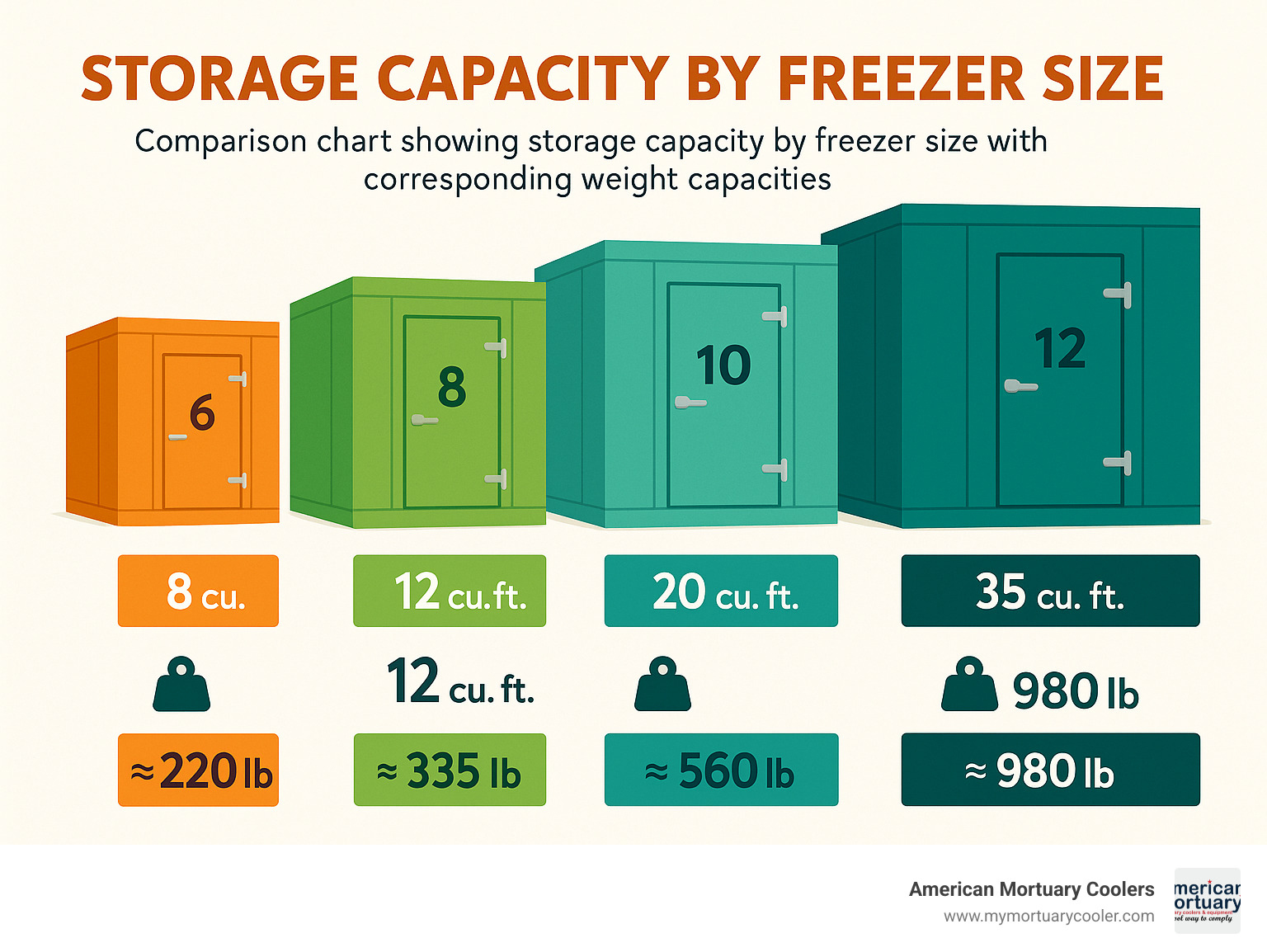

Getting the size right is where many businesses stumble. Too small, and your walkin freezer works overtime trying to keep up. Too big, and you're paying for space you don't need while watching your energy bills climb.

Calculating the right walkin freezer volume

Here's the golden rule: one cubic foot holds about 28 pounds of frozen food. But before you grab your calculator, let's talk about what really matters in your operation.

How often do deliveries arrive? If trucks show up daily, you can get by with less storage. But if you're like most operations receiving weekly shipments, you'll need room for everything that arrives on delivery day.

What's your busiest time look like? Don't size for your average Tuesday - plan for your peak season. That catering company preparing for graduation season or the restaurant gearing up for the holidays needs capacity for maximum inventory, not typical levels.

Your delivery frequency and peak inventory needs work together. A facility getting deliveries twice weekly might need 3.5 times their daily usage, while weekly deliveries require a full week's capacity plus buffer space.

Shelf clearance isn't optional - it's required for proper airflow and health codes. You'll lose space to the mandatory 2-inch gap around walls and 6-inch clearance above the floor. Factor this into your calculations from the start.

Product turnover varies dramatically by industry. A busy restaurant cycles through inventory quickly, while a mortuary or medical facility might store items longer-term. Faster turnover means you can optimize for less storage space relative to volume.

Future growth planning saves money long-term. Adding 20-30% capacity beyond current needs costs far less than replacing your entire walkin freezer when business expands.

Indoor vs outdoor placement

Location affects everything from your initial investment to daily operations.

Indoor units fit neatly into existing buildings but come with space constraints. You'll need that 2-inch air gap around all panels, and freezer applications absolutely require insulated flooring to prevent heat transfer through concrete. The upside? Weather never affects performance, and you avoid the additional components outdoor units require.

Outdoor placement frees up valuable interior space but demands extra investment in weather kits, vinyl roofs, and concrete pads. The concrete must be level within 1/4 inch per 10 feet - any more variation causes panel alignment issues and potential seal failures.

Outdoor walkin freezer units aren't limited by your building's dimensions. You can install exactly the size you need without compromising on capacity or awkward configurations to fit existing spaces.

Components & Technology Deep-Dive

When you're investing in a walkin freezer, understanding what goes into the construction makes all the difference. The engineering behind modern freezer units has evolved into sophisticated systems that balance energy efficiency, durability, and precise temperature control.

Insulation & R-values that matter

The Federal Energy Independence and Security Act (EISA) requires freezers to have at least R-32 insulation values. That's the minimum, but quality manufacturers often exceed these standards because better insulation means lower operating costs for you.

Polyurethane foam is the gold standard for freezer insulation. It offers superior R-value per inch and resists moisture like a champ. The best units use foamed-in-place polyurethane that creates seamless insulation without those pesky thermal bridges that can cause cold spots.

Extruded polystyrene is another proven option, especially in high-moisture environments. This material maintains consistent R-value even when exposed to water, making it perfect for applications where moisture might be an issue.

Quality panel construction uses 26-gauge coated steel panels with cam-action locks and compression gaskets. These create rigid, air-tight joints that keep the cold in and the heat out. Some manufacturers go with seamless fiberglass construction that eliminates thermal bridges entirely.

Don't overlook vapor barriers - they prevent moisture from sneaking into your insulation and compromising performance.

Refrigeration system choices for a walkin freezer

The refrigeration system is the heart of your walkin freezer. Get this wrong, and you'll have headaches for years.

Self-contained units put everything in one package - evaporator and condensing unit together, usually mounted on the roof or wall. They're simpler to install, but they can be noisier and have capacity limitations.

Remote systems separate the condensing unit from the evaporator. This lets you put the noisy, heat-producing condenser somewhere else entirely. You'll get better performance and quieter operation, but you'll need to run refrigerant lines between components.

For extreme cold applications, Improved Vapor Injection (EVI) compressors are game-changers. They improve efficiency in low-temperature situations while reducing energy consumption.

Defrost systems prevent ice buildup that can kill performance. Electric defrost uses heating elements for 30-40 minute cycles three times daily. Hot gas defrost uses refrigerant for shorter 15-18 minute cycles. Both should terminate at 48°F coil temperature to prevent over-defrosting and condensation problems.

Flooring, doors & accessories

The details matter when it comes to walkin freezer components. These elements make the difference between a unit that serves you well and one that causes constant problems.

Heavy-gauge aluminum floor panels rated for 600 pounds per square foot provide the durability you need. Diamond-plate surfaces offer slip resistance - crucial when you're working in freezing conditions. Coved corners make cleaning easier, and insulated flooring prevents heat transfer through concrete slabs.

Door configurations typically start with standard 34" x 78" personnel doors featuring adjustable spring-assisted hinges and heated pressure-relief vents. Larger operations might need 36" doors or specialized roll-up doors for forklift access. Every door must include glow-in-the-dark safety releases per OSHA requirements - safety isn't optional.

Essential accessories include strip curtains that reduce air infiltration during frequent access, LED lighting for energy-efficient illumination, and temperature monitoring systems with data logging capabilities. Don't forget about shelving systems designed specifically for freezer environments and ramps for wheeled cart access.

Installation, Operation & Energy Efficiency

Getting your walkin freezer properly installed and running efficiently makes all the difference between a reliable workhorse and an energy-guzzling headache.

The installation process starts with proper site preparation and electrical connections. Your concrete pad needs to be level within 1/4 inch per 10 feet, and you'll want adequate drainage to prevent water accumulation around outdoor units. Following Federal cold storage guidelines helps ensure both food safety and optimal performance.

Best practices to run an efficient walkin freezer

Running an efficient walkin freezer comes down to smart habits and the right equipment choices. Door discipline ranks as the single most important factor - every time that door opens, cold air rushes out and warm air floods in. Training your staff to grab everything they need in one trip and close the door quickly can slash your energy bills.

LED lighting transforms both energy consumption and working conditions inside your freezer. These systems use 75% less energy than old incandescent bulbs while providing better visibility and generating virtually no heat.

Fan delay timers keep the evaporator fans off for 5-7 minutes after each defrost cycle, allowing water to drip properly instead of getting blown around and turning into ice.

ECM motors in your evaporator fans provide variable speed control that adjusts to actual cooling needs rather than running full-blast all the time. Think of it like cruise control for your freezer.

Installing strip curtains helps maintain temperature during extended access periods, especially useful in high-traffic operations.

Common maintenance & troubleshooting tips

Regular maintenance keeps your walkin freezer running reliably and prevents those middle-of-the-night emergency service calls.

Coil cleaning should happen quarterly, though dusty environments might need monthly attention. Dirty evaporator and condenser coils force your system to work harder. Clean coils transfer heat efficiently, while dirty ones drive up energy costs and shorten equipment life.

Gasket inspection takes just minutes but prevents major problems. Check door gaskets monthly for tears, warping, or hardening that compromises the seal. A simple dollar bill test works well - if you can pull the bill out easily when it's closed in the door, your gasket needs attention.

Ice buildup on walls or coils signals trouble, usually from air infiltration through damaged seals or panel joints. Sometimes the problem stems from improper defrost settings that don't fully clear the coils or terminate too early.

Defrost cycle monitoring ensures your system completes proper cycles. The coils should reach about 48°F during defrost, then cool back to 20°F before the fans restart.

Temperature logging serves double duty - it keeps you compliant with health regulations while providing early warning of developing problems.

Cost breakdown & warranties

Understanding the real costs helps you make smart decisions about your walkin freezer investment.

Initial investment typically runs $15,000-$25,000 for the unit itself, with installation adding another $2,500-$4,000. Outdoor installations may need additional site preparation, concrete pads, and weather protection.

Operating costs vary dramatically between efficient and standard units. Energy-efficient models can consume 6,049 kWh annually compared to 16,085 kWh for basic metal panel units. That difference translates to over $1,000 in annual energy savings.

Lifecycle analysis reveals the true value proposition. When you divide total costs by the typical 15-year useful life, quality units often cost less per year than cheaper alternatives that consume more energy or require frequent repairs.

Warranty coverage from reputable manufacturers includes 15-20 year panel warranties, 5-year coverage on doors and compressors, plus 1-year parts and labor protection.

For detailed cost analysis and financing options, check out our Commercial Walk-In Freezer Cost guide. You can also find additional energy-saving tips at Save on Energy to further reduce your operating costs.

Organization, Safety & Compliance

Running a walkin freezer safely and efficiently goes beyond just keeping things cold. Smart organization and proper compliance create a foundation for smooth operations while protecting your staff and products.

Smart layout inside your walkin freezer

Think of your walkin freezer interior like a well-designed kitchen – everything should have its place and purpose. The most effective layouts start with perimeter shelving that hugs the walls while leaving a clear center pathway. This approach maximizes your storage space without creating a maze that slows down your team.

Clearance requirements aren't just suggestions – they're essential for proper airflow and regulatory compliance. Keep at least 2 inches between shelves and walls to let cold air circulate freely. Your lowest shelf needs to sit 6 inches above the floor for easy cleaning and to meet health department standards.

Product zoning makes a huge difference in both safety and efficiency. Store raw meats on bottom shelves to prevent any drips from contaminating other products. Group similar items together and position your most frequently accessed products near the entrance.

FIFO rotation (First In, First Out) becomes second nature with proper labeling. Use clear, freezer-safe labels with product names and dates, then place older items at the front where they're impossible to miss.

All your shelving and storage containers should carry the NSF certification – look for that distinctive blue NSF label that confirms the equipment is safe for food contact.

Regulations every operator must know

OSHA Standard 1910.36(d)(1) addresses one of the most critical safety concerns: exit doors must open from inside without keys, tools, or special knowledge. This isn't optional – it's literally a matter of life and death. Interior safety releases and optional alarms provide additional protection for your team.

NSF Standard 7 governs how food equipment should be constructed and what materials are acceptable. If you're handling food products, you'll need aluminum or stainless steel flooring with proper radius coves to meet these requirements.

UL listings ensure your panels and doors meet strict standards for flame spread, smoke development, and electrical safety. Don't cut corners here – proper UL-listed components protect your entire facility.

EISA compliance sets the baseline for energy efficiency with minimum R-32 insulation requirements for freezers. Quality units often exceed these standards, which benefits both your energy bills and the environment.

Local building codes can add their own requirements, especially in areas prone to earthquakes, high winds, or heavy snow loads. Some locations require wet-stamped engineering documents before installation.

For additional guidance on energy efficiency and potential utility rebates, the save on energy tips resource offers practical advice. The Federal cold storage guidelines provide comprehensive food safety standards that complement your walkin freezer operations.

Frequently Asked Questions about Walk-In Freezers

After years of helping facilities choose the right cold storage solutions, we've heard just about every question imaginable about walkin freezers. Here are the most common ones that come up during our consultations.

How low can a walkin freezer go and still be safe?

The sweet spot for most walkin freezer applications sits between 0°F and -10°F. This range handles virtually all frozen food storage needs while maintaining reasonable operating costs and system reliability.

Specialized applications can push these limits much further. We've worked with facilities requiring -50°F or even lower for specific pharmaceutical or research applications. These ultra-low temperature units need beefed-up insulation, specialized compressor systems, and extra safety features that standard freezers don't require.

The real question isn't just "how low can it go?" but rather "how low do you need it to go consistently?" A walkin freezer that struggles to maintain -30°F will cost you more in energy bills and repairs than a properly sized unit running at -10°F.

What's the difference between self-contained and remote?

Think of self-contained systems as the all-in-one solution – everything's packaged together in one unit that typically sits on top of your freezer or mounts on the wall. Installation is straightforward since there's no need to run refrigerant lines between components.

The trade-off? These units have limited capacity and can be quite noisy since all the mechanical components are right there with your storage area. They're perfect for smaller operations or situations where simplicity trumps performance.

Remote systems take a different approach by separating the noisy, heat-producing condenser from the evaporator inside your walkin freezer. The condenser can be located outside or in a mechanical room, while only the quiet evaporator stays with your storage space.

This separation delivers several advantages: better performance and efficiency, much quieter operation inside the freezer, greater capacity options, and easier maintenance access. The downside is higher upfront installation costs since you need professional refrigerant line installation.

How do I stop ice from building on the coils?

Ice buildup on coils is like a fever – it's a symptom telling you something else is wrong. Most ice problems have straightforward solutions once you identify the root cause.

Air infiltration causes most ice headaches. Warm, humid air sneaking into your walkin freezer hits those cold coils and instantly turns to ice. Start by checking your door gaskets – they're the usual suspects. Look for tears, warping, or areas where the seal doesn't make solid contact.

Don't overlook the panel seams either. Over time, these joints can develop small gaps that let in surprising amounts of air. A little sheet metal work and butyl sealant can solve these problems permanently.

Strip curtains make a huge difference if your staff needs frequent access to the freezer. They act as a secondary barrier, keeping most of the warm air out even when the main door opens.

Sometimes the problem lies with your defrost system settings. The defrost cycle should terminate when coils reach about 48°F, then wait 5-7 minutes before restarting the fans. This gives melted ice time to drip away instead of getting flung around the freezer when fans kick back on.

Conclusion

After diving deep into walkin freezers, you now have the knowledge to make an informed decision that'll serve your business for years to come. The key isn't just finding the biggest unit or the cheapest price – it's about finding the right balance between your specific needs, budget, and long-term goals.

Think of your walkin freezer as a long-term business partner. When you invest in quality construction with proper R-32 insulation, choose the right refrigeration system for your application, and ensure professional installation, you're setting yourself up for 15 years of reliable service.

The fundamentals we've covered really do make the difference. Proper sizing based on your actual storage needs prevents costly oversizing or frustrating capacity shortages. Regular maintenance like cleaning those coils and checking door gaskets keeps your system running efficiently. And staff training on simple things like closing doors quickly can save hundreds in energy costs annually.

At American Mortuary Coolers, we've seen how the right walkin freezer transforms operations across Tennessee, Atlanta, Chicago, Columbia, Dallas, Los Angeles, New York, and Pittsburgh. Whether it's a busy restaurant keeping up with dinner rushes or a mortuary facility maintaining precise temperature control, the same principles apply: quality equipment, proper installation, and consistent care.

For our specialized mortuary clients, we understand that your needs go beyond basic cold storage. Our custom solutions with discrete exteriors and precise temperature control meet the unique requirements of funeral service professionals. We deliver these specialized units nationwide across the contiguous 48 states.

The beauty of a well-chosen walkin freezer is that it becomes invisible to your daily operations – in the best possible way. It quietly maintains perfect temperatures, protects your valuable inventory, and supports your business goals without drama or unexpected breakdowns.

Ready to take the next step? Our guide to Commercial Walk-In Freezers That Are Cooler Than Cool offers additional insights for selecting your perfect system.

You're not just buying equipment – you're investing in reliable cold storage that protects what matters most to your business. Choose thoughtfully, maintain consistently, and your walkin freezer will reward you with years of dependable service.