Lift Cart 101: Everything You Need to Know Before Buying

Why Lift Carts Are Essential for Modern Material Handling

A lift cart is a mobile hydraulic or electric platform that raises and lowers heavy loads to ergonomic working heights, combining the functionality of a cart with adjustable lifting capabilities. These versatile material handling tools eliminate manual lifting strain while improving workplace safety and productivity.

Key Lift Cart Benefits:

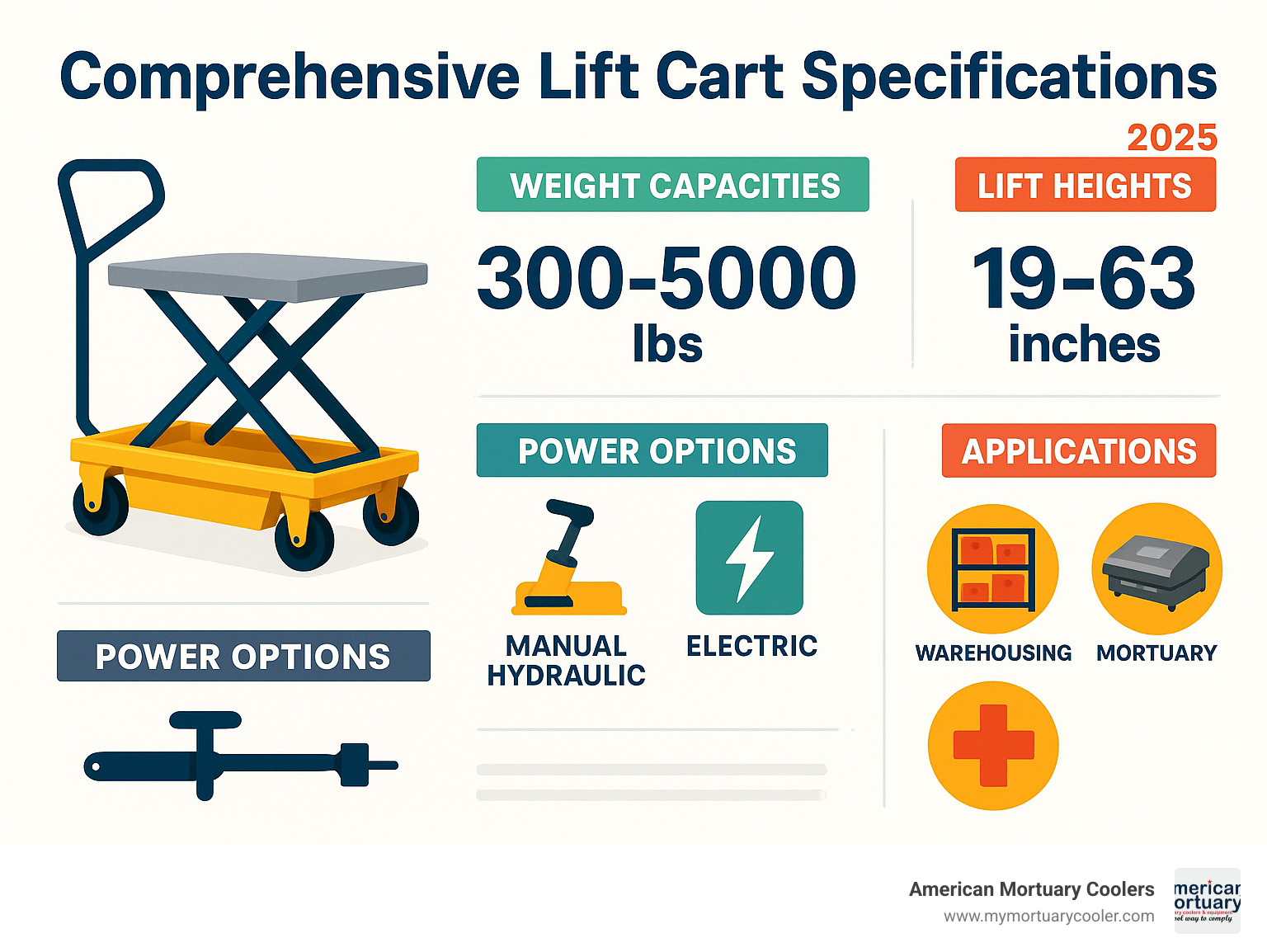

- Weight capacity: 300-5,000 lbs depending on model

- Lift height range: 19-63 inches for ergonomic positioning

- Injury reduction: Up to 30% decrease in workplace injuries

- Productivity boost: 30% increase in material handling efficiency

- Power options: Manual hydraulic, electric, or battery-powered

Lift carts work by using hydraulic scissor mechanisms or electric motors to smoothly raise platforms loaded with materials, equipment, or other heavy items. The mobile design with swivel casters allows operators to transport loads while maintaining proper ergonomic height throughout the workflow.

Workplace studies show that using lift carts can increase material handling efficiency by up to 30% and reduce the risk of musculoskeletal injuries. This makes them invaluable across industries from warehouses and manufacturing to healthcare facilities and funeral homes.

Mobile lift carts handle weight capacities ranging from 300 lbs for light-duty applications up to over 5,000 lbs for heavy industrial use. Manual hydraulic models typically require 25-70 pedal strokes to reach maximum height, while electric versions operate continuously for several hours on a single charge.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes select the right lift cart solutions for their specific operational needs. My background includes working with facilities across the country to implement ergonomic material handling equipment that improves both safety and efficiency.

Lift cart terms made easy:

Why Every Facility Should Consider a Lift Cart

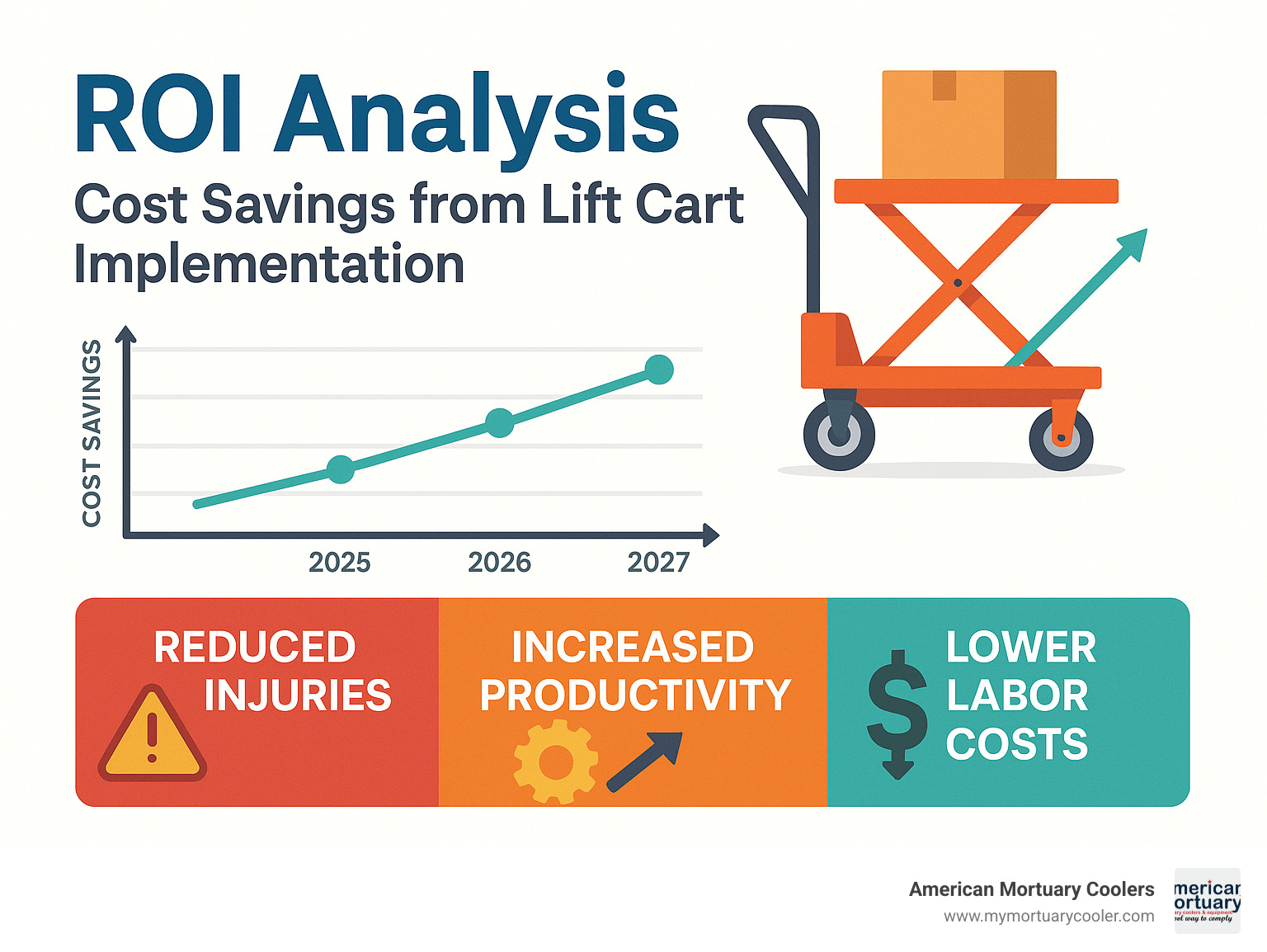

The numbers don't lie - facilities that implement lift carts see immediate improvements in both productivity and worker safety. Our research shows that operations experience a 30% productivity gain when workers can transport and position heavy loads without manual lifting strain.

The weight capacity range of 300-5,000 lbs means there's a lift cart solution for virtually every material handling challenge. Whether you're moving boxes in a warehouse, positioning equipment in a workshop, or handling specialized loads in a mortuary, the right lift cart eliminates the physical stress that leads to injuries and inefficiency.

How Lift Carts Work & Core Components

Think of a lift cart as a mechanical helper that does the heavy lifting so your workers don't have to. The beauty lies in how these components work together seamlessly - when you step on that foot pedal or press the electric button, you're setting off a chain reaction that transforms physical effort into smooth, controlled lifting power.

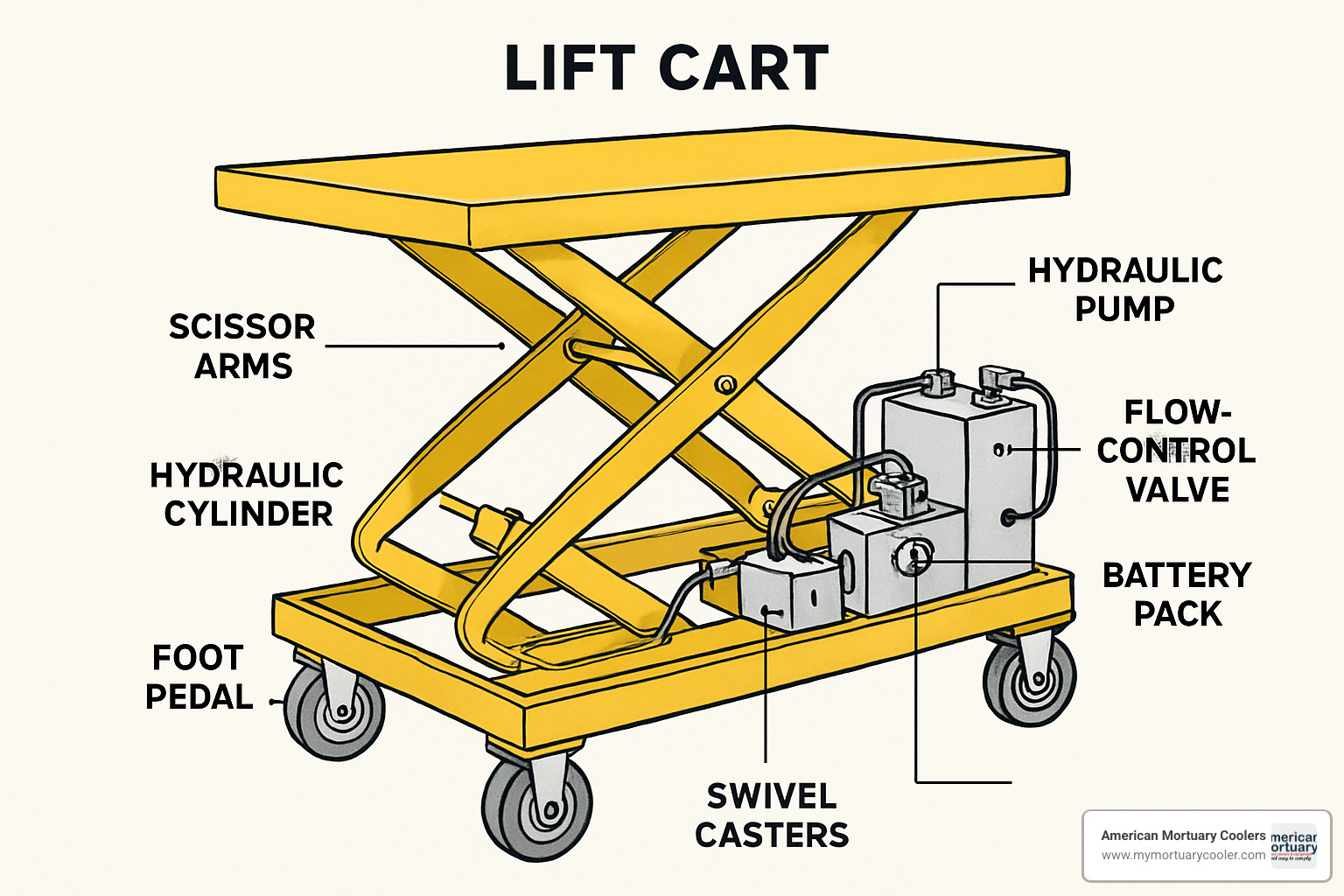

At the heart of every lift cart sits the hydraulic pump, which creates the pressure needed to lift heavy loads. This pressure flows to hydraulic cylinders that convert that fluid force into the mechanical power that moves the scissor arms up and down. It's like watching a perfectly choreographed dance between engineering components.

The foot pedal on manual models gives operators complete control over the lifting process, while battery packs on electric versions eliminate the need for any manual pumping effort. Swivel casters underneath keep everything mobile and maneuverable, and the flow-control valve ensures loads come down smoothly instead of dropping suddenly.

Lift Cart 101: Core Mechanism

The big decision most facilities face is choosing between hydraulic and electric drive systems. Manual hydraulic models require anywhere from 25 to 70 pedal strokes to reach full height, depending on what you're lifting and how high you need to go. It's honest work, but it does require some physical effort from your operators.

Electric systems flip this equation entirely. Instead of your workers doing the pumping, a battery-powered motor handles all the hydraulic pressure building. This means lift cycle times become much faster and more consistent - no more waiting for someone to pump up the platform between loads.

Dual-wheel brakes might seem like a small detail, but they make a huge difference in real-world use. When you're loading or unloading heavy items, the last thing you want is your cart rolling away from you. Quality brakes engage easily and hold firm, giving operators confidence and safety.

Inside the Hydraulic System

The hydraulic system operates on pressure ratings between 1,500 and 3,000 PSI - that's serious lifting power contained in a relatively compact system. The number of pedal strokes you'll need depends on cylinder size and how high you're lifting. Larger cylinders move more fluid per stroke but need more force to operate.

What separates good lift carts from great ones is smooth lowering control. Precision flow-control valves regulate how fast loads descend, preventing those heart-stopping moments when something heavy starts dropping too quickly. Operators can usually adjust the descent speed to match their comfort level and load requirements.

Fluid checks keep everything running smoothly over the long haul. Low hydraulic fluid causes erratic lifting and jerky operation, while dirty fluid can damage expensive seals and cylinders. A quick monthly check of fluid levels and an annual fluid change will keep your lift cart performing like new for years to come.

Main Lift Cart Types & Industry Applications

When it comes to lift carts, one size definitely doesn't fit all. The beauty of these workhorses lies in their variety - there's a specialized model for just about every material handling challenge you can imagine.

Manual hydraulic models are the reliable workhorses that most facilities start with. These foot-pump operated carts cost between $300-$3,000 and handle up to 2,200 lbs with ease. They're perfect for warehouses, workshops, and any operation where you need occasional lifting help without breaking the budget.

Electric scissor carts take things up a notch by eliminating that foot-pumping workout. With battery power doing the heavy lifting, these models can handle up to 5,000 lbs and keep going for hours on a single charge. If your team is doing dozens of lifts daily, the electric route quickly pays for itself in reduced fatigue and increased productivity.

For the ultimate in convenience, powered drive carts combine electric lifting with motorized movement. These premium models let operators glide heavy loads across facilities without any pushing or pulling - it's like having a forklift that fits through doorways.

Low-profile models solve the common problem of getting loads onto the cart in the first place. With lowered heights as minimal as 12 inches, these carts make it easy to slide heavy items on from floor level or squeeze under tight clearances.

Tilt and scale carts add specialized functionality that can transform workflows. Tilt models let you dump containers with controlled precision, while scale-equipped versions eliminate separate weighing steps by building measurement right into the lifting process.

Manual vs Electric Lift Cart

The manual versus electric decision often comes down to how hard you're planning to work your lift cart. Manual models shine when you need occasional lifting help and want to keep costs low. They're simple, reliable, and require minimal maintenance beyond checking hydraulic fluid and caring for the casters.

Electric models become the smart choice when your operation demands more than 30-40 lifts per day. The initial investment of $2,000-$10,000 feels steep compared to manual models, but the math changes quickly with heavy use. Your team stays fresher, work flows faster, and consistency improves when operators aren't getting tired from pumping.

Maintenance requirements differ significantly between the two. Manual systems are beautifully simple - keep the hydraulic fluid clean and the casters rolling smoothly, and you're set. Electric models need battery care, electrical system checks, and more complex troubleshooting when things go wrong.

The return on investment calculation is straightforward: if you're lifting frequently, electric pays for itself through improved productivity and reduced operator fatigue. For occasional use, manual models deliver excellent value without the complexity.

Specialty Lift Carts for Mortuary Operations

Funeral homes face unique challenges that standard lift carts simply can't handle. The combination of heavy loads, hygiene requirements, and the dignity of the work demands specialized equipment designed specifically for mortuary operations.

Body and casket lifts feature stainless steel construction that cleans easily and resists corrosion. These models typically handle 1,000+ lbs while maintaining low-profile loading heights of 12-15 inches for easy transfers. Specialized restraint systems and easy-clean surfaces address the specific needs of funeral home workflows.

Crematory scissor lifts take specialization even further with heat-resistant components and platform configurations designed for crematory procedures. These units help position bodies safely and ergonomically, reducing physical strain on staff during sensitive operations.

For funeral homes considering crematory equipment, our detailed guide on Elevating Efficiency and Safety: The Essential Role of Crematory Scissor Lifts covers the specific requirements and benefits of these specialized systems.

Heavy-Duty & Rough-Terrain Models

Some jobs demand lift carts that can handle extreme conditions. Heavy-duty models supporting up to 5,000 lbs feature reinforced frames, larger hydraulic cylinders, and industrial-grade components built to withstand demanding applications.

Rough-terrain models equipped with pneumatic tires transform lift carts from indoor-only tools into versatile outdoor workhorses. These models handle uneven surfaces, outdoor storage, and even operation on slopes where standard casters would fail completely.

The combination of weather-resistant components and improved stability makes these carts essential for outdoor yards, construction sites, and industrial facilities. While they cost more than standard models, the ability to work in challenging environments often makes them irreplaceable for specific applications.

Choosing the Best Lift Cart: Key Specs & Cost Factors

Finding the perfect lift cart for your facility isn't just about picking the biggest or cheapest option. It's about matching the right specifications to your daily operations and long-term needs.

The most critical factor is weight capacity - and here's where many buyers make their first mistake. Don't just consider your heaviest load; add at least 20% safety margin. If you're moving 400-pound caskets, look for a cart rated at least 500 pounds. This buffer protects both your equipment and your team.

Lift height range determines whether your lift cart will actually improve ergonomics or just move the problem around. Most quality models lift from 19 to 63 inches, putting loads in that sweet spot where workers don't strain their backs. Think about your tallest and shortest employees - the cart should work comfortably for everyone.

Platform size creates another balancing act. You need enough space for your largest loads, but the cart still has to steer your facility's doorways and tight corners. Standard platforms range from compact 18" x 18" squares up to generous 63" x 31.5" rectangles.

The power source decision often comes down to how often you'll use the cart. Manual models save money upfront but require physical effort every time. Electric versions cost more initially but eliminate operator fatigue and speed up repetitive tasks.

Cycle frequency - how many times per day you'll raise and lower loads - determines your best value choice. If you're lifting loads more than 30-40 times daily, electric models typically pay for themselves through improved productivity and reduced worker strain.

Your facility's footprint constraints matter too. Measure your narrowest aisles and doorways before falling in love with a particular model. A cart that can't reach where you need it becomes an expensive paperweight.

Lift Cart Capacity & Lift Range Calculator

Getting your lift cart specifications right requires honest assessment of your actual loads and working conditions. This isn't the time for guesswork.

Load weight calculations need to include everything that goes on the platform. That 200-pound load becomes 250 pounds when you add the pallet or container. Factor in any fixtures, straps, or handling equipment too.

Center of gravity can make or break your cart selection. Loads that sit off-center or have uneven weight distribution need higher capacity ratings and sometimes specialized restraint systems. Caskets, for example, have most of their weight concentrated in the body area.

The ergonomics zone between 30 and 48 inches high is where your workers will be most comfortable and productive. This "golden zone" minimizes bending, reaching, and the awkward positions that lead to injuries.

Your heaviest load might not be your most challenging one. Sometimes lighter but awkwardly shaped items require more careful cart selection than straightforward heavy loads.

For detailed specifications and professional guidance on matching carts to specific applications, our partners at Mobile lift specifications offer comprehensive selection tools.

Budgeting & ROI

Lift cart pricing spans a wide range, and understanding why helps you make smarter buying decisions. The difference between a $500 cart and a $5,000 cart isn't just about capacity - it's about construction quality, expected lifespan, and total cost of ownership.

Basic manual models start around $300 for light-duty applications and climb to $1,500 for mid-range units. These work well for occasional use and budget-conscious operations.

Mid-range hydraulic carts in the $1,500 to $4,000 range offer better build quality and higher capacities. They're the sweet spot for most facilities with moderate usage.

Electric models begin around $2,000 and can reach $8,000 for premium units. The extra cost buys convenience, speed, and reduced operator fatigue.

Heavy-duty and specialty units command $5,000 to $10,000+ but provide capabilities that standard carts simply can't match.

Leasing options make higher-end models more accessible, with monthly payments starting around $191 for quality European models. Leasing preserves capital and can provide tax advantages, though total cost will exceed purchase price.

The real value calculation includes factors beyond the purchase price. Reduced injury costs from proper ergonomics can save thousands in workers' compensation claims. Decreased downtime from faster material handling improves overall productivity. Extended equipment life from proper handling protects your other investments.

A facility that prevents just one back injury per year through proper lift cart use often saves more than the cart's entire purchase price. When you factor in improved productivity and reduced worker fatigue, quality lift carts typically pay for themselves within 12 to 18 months.

For comprehensive product catalogs and current pricing, the Elevating Lift Carts catalog provides detailed specifications across all major manufacturers.

Safety, Ergonomics & Maintenance Best Practices

Getting the most from your lift cart means treating safety and maintenance as seriously as you would any other piece of equipment in your facility. Think of it this way - a well-maintained lift cart is like a reliable employee who shows up every day ready to work.

Operator training forms the foundation of safe lift cart operation. Even though these machines look straightforward, proper loading techniques and weight distribution can mean the difference between smooth operation and a workplace accident. Your team needs to understand not just how to pump the pedal, but how to recognize when something isn't working right.

The right personal protective equipment varies by application, but safety shoes are non-negotiable when working around heavy loads. Depending on what you're lifting, gloves and back support belts might also make sense for your operation.

Floor conditions play a bigger role than most people realize. Your beautiful lift cart will perform like a champion on smooth, level surfaces, but throw some debris or uneven flooring into the mix, and you might need to consider pneumatic tires or rough-terrain models instead.

Creating OSHA-style checklists might sound like bureaucratic overkill, but they're actually your best friend for catching problems before they become expensive repairs or safety incidents. A quick daily check of brake function, hydraulic fluid levels, and caster condition takes less than five minutes but can save you hours of downtime later.

Operating a Lift Cart Safely

Safe lift cart operation starts before you even load anything onto the platform. Brake engagement should become as automatic as putting on your seatbelt - always lock those wheels before loading or unloading. It's amazing how quickly a seemingly stable cart can roll away when you least expect it.

Even load distribution isn't just about preventing tip-overs, though that's certainly important. Properly centered loads make the entire system work more smoothly and put less stress on the hydraulic components. If your load wants to shift around, secure it properly rather than hoping for the best.

Every lift cart operator should know the emergency stop procedures for their specific model. Electric models typically have clearly marked emergency stops, but manual models require knowing how to quickly release hydraulic pressure. Practice these procedures when you're not under pressure so they become second nature.

Wheel chocking becomes critical when working on any kind of slope. Don't rely solely on brakes when gravity is working against you - use proper wheel chocks as backup protection.

The golden rules are simple: never exceed rated capacity, keep your hands and feet away from moving parts, maintain clear sight lines while moving, and follow the manufacturer's procedures. These aren't suggestions - they're the difference between going home safe and going home hurt.

Preventive Maintenance Checklist

Regular maintenance transforms your lift cart from a piece of equipment that might work into one you can count on every single day. The key is establishing routines based on how often you use the cart and what kind of environment it works in.

Daily visual checks take just a few minutes but catch most problems early. Look for damaged casters or debris wrapped around wheels, test your brakes to make sure they still grip properly, and check for any hydraulic fluid puddles under the cart. Run through the lift and lower functions to make sure everything moves smoothly, and give the platform a quick inspection for any new damage.

Monthly maintenance goes a bit deeper into the system. Check hydraulic fluid levels and top them off if needed - low fluid is one of the fastest ways to damage expensive components. Lubricate those caster swivels and wheel bearings so they keep rolling smoothly. Take a close look at hydraulic hoses for signs of wear or damage, and clean any debris that's built up in the scissor mechanisms. If you have an electric model, test those emergency stops to make sure they're working properly.

Annual service is when you get serious about long-term reliability. Replace hydraulic fluid and filters completely, inspect and replace any worn seals before they fail, and check all electrical connections on powered models. If your cart has built-in scales, this is when you calibrate them for accuracy. Consider having a professional inspection of structural components - it's cheaper than replacing a cart that failed catastrophically.

For funeral homes and mortuaries, maintenance takes on special importance due to the sensitive nature of the work. You can find detailed guidance specifically for mortuary applications in our article on mortuary lift maintenance.

Conclusion & Next Steps

The journey through lift cart technology brings us to an important realization: these aren't just pieces of equipment—they're investments in your team's wellbeing and your operation's future. When you eliminate the daily strain of manual lifting, you're not just preventing injuries; you're creating a workplace where people can focus on what matters most.

At American Mortuary Coolers, we've seen how the right lift cart transforms funeral home operations. From our Tennessee headquarters, we've worked with facilities across the country—from busy funeral homes in Chicago and New York to smaller operations throughout the Southeast and Pacific regions. Each installation tells the same story: better equipment leads to better outcomes for everyone involved.

Your funeral home faces unique challenges that generic material handling equipment simply can't address. That's why we specialize in customized mortuary lift carts that meet the specific demands of your daily operations. Whether you're moving bodies, positioning caskets, or handling heavy equipment, we understand the dignity and care your work requires.

The path forward starts with honest assessment. Take a close look at your current material handling processes—where do your staff struggle most? What tasks cause the most physical strain? These pain points guide us toward the perfect solution, whether that's a simple manual hydraulic model or a sophisticated electric system with specialized features.

Choosing between manual and electric comes down to your usage patterns and budget considerations. Facilities using lift carts more than 30 times daily typically see better returns with electric models, while occasional-use operations often prefer the simplicity and lower cost of manual systems.

Total cost of ownership tells the real story of value. When you factor in reduced injury claims, improved productivity, and extended equipment life from proper handling, even premium models often pay for themselves within the first year. We've helped countless funeral homes justify their investment through these tangible benefits.

The mortuary industry deserves equipment designed specifically for its needs. Generic warehouse carts simply don't offer the stainless steel construction, easy-clean surfaces, and specialized dimensions that make funeral home work safer and more dignified. That's where our expertise makes the difference.

Ready to move forward? Start by requesting a consultation with our team. We'll discuss your specific needs, facility layout, and budget considerations to recommend the perfect lift cart solution. Our direct delivery service means you'll have your equipment installed and ready to work quickly, with full support throughout the process.

For comprehensive guidance on selecting the right equipment for your facility, we recommend exploring The Ultimate Guide to Choosing the Best Mortuary Lift System. This resource covers everything from basic specifications to advanced features that can transform your daily operations.

Your team deserves better than struggling with manual lifting day after day. Lift carts represent proven technology that's helped thousands of facilities improve safety, efficiency, and working conditions. The question isn't whether you need better material handling—it's which solution will serve your funeral home best.

Contact American Mortuary Coolers today to begin your journey toward safer, more efficient operations. We're here to help you select, customize, and implement the lift cart solutions that will serve your funeral home for years to come.