Scalpel Knife 101: Everything You Didn't Know You Needed to Know

What Every Professional Needs to Know About Scalpel Knives

A scalpel knife is a small, extremely sharp bladed instrument used for surgery, anatomical dissection, podiatry, and various crafts. Here's what you need to know:

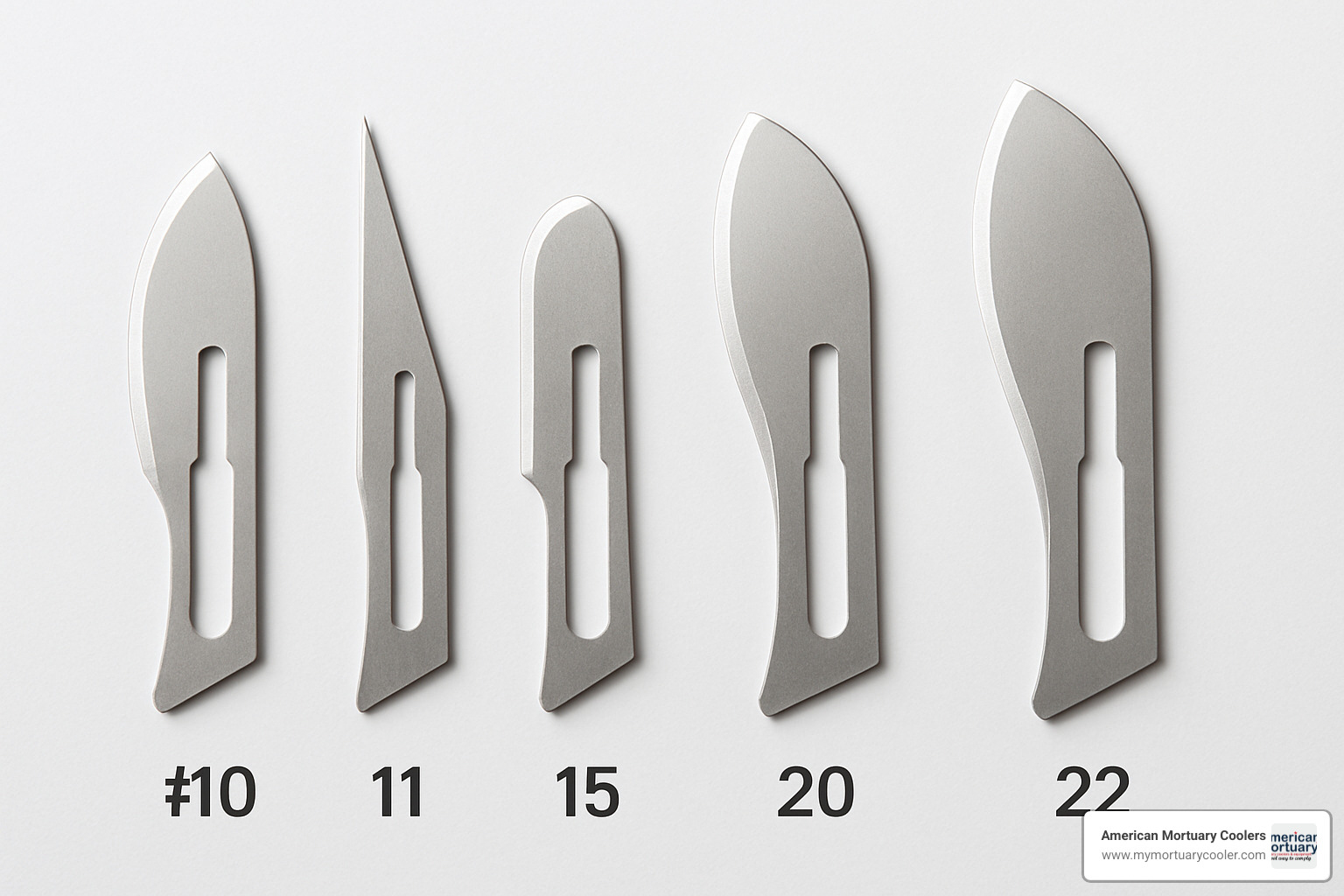

Key Facts: - Definition: Also called a bistoury or lancet, it consists of a handle and detachable blade - Main Uses: Surgery, autopsy procedures, dermaplaning, model-making, woodcarving - Blade Numbers: #10 (skin incisions), #11 (stab wounds), #15 (delicate work), #22 (autopsy) - Materials: High-carbon steel, stainless steel, titanium, ceramic, or obsidian blades - Safety Stats: Scalpel injuries make up 7-8% of all sharps injuries among healthcare workers

The history of scalpel knives stretches back over 4,000 years. Archaeological evidence shows obsidian scalpels were used for brain surgery in Bronze Age settlements in Turkey around 2100 BC. The modern two-piece design we know today was patented by Morgan Parker in 1915, allowing for cold sterilization without dulling the blade.

Modern scalpel knives come in several types:

- Surgical (sterile, single-use)

- Craft knives (hobby and professional use)

- Safety scalpels (retractable blades)

- Folding scalpels (portable designs)

As professionals at American Mortuary Coolers with years of experience supplying precision instruments to funeral homes nationwide, we've seen how the right scalpel knife can make all the difference in preparation room efficiency and safety. Our background in mortuary equipment has shown us that quality cutting tools are essential for professional results.

What Is a Scalpel (Scapple) Knife?

When you hear the word "scalpel," you might immediately think of surgery - and you'd be right. But there's more to this precision instrument than meets the eye. The term comes from the Latin "scalpellum," which simply means "small knife." You'll sometimes see it written as "scapple knife" - don't worry, that's not a typo. It's just an alternative spelling that pops up in certain regions and industries.

Throughout history, this essential tool has worn many names. Medical professionals have called it a bistoury or lancet, depending on its specific design and intended use. But regardless of what you call it, its purpose remains the same: to make precise, controlled cuts.

The beauty of a scalpel lies in its neat simplicity. Every scalpel has just two main parts - a handle that gives you control, and a detachable blade that does the actual cutting. This brilliant design means you can maintain perfect sterility by simply swapping out blades while keeping the same handle.

What's truly amazing is how ancient this concept is. Archaeologists have found obsidian scalpels in Bronze Age settlements in Turkey that are over 4,000 years old. These weren't just simple tools either - they were used for complex procedures like trepanation, which involved drilling holes in skulls.

The game-changer came in 1915 when Morgan Parker patented the two-piece design we know today. This wasn't just a minor improvement - it solved a major problem that had plagued surgeons for centuries. Before this innovation, sterilizing scalpels would dull their blades. Parker's design allowed for cold sterilization without losing that crucial sharp edge.

Core Components & Materials

Today's scalpel blades are marvels of materials science. High-carbon steel remains the gold standard for most applications. It holds an incredibly sharp edge and keeps that sharpness longer than other materials.

Stainless steel blades offer different advantages - they resist corrosion and are easier to sterilize. This makes them perfect for medical environments where cleanliness is paramount.

For specialized situations, we see fascinating alternatives. Titanium blades are essential for MRI-guided procedures because they're non-magnetic. Ceramic blades push sharpness to new levels while never rusting. They're incredibly hard and maintain their edge well, though they can be more brittle than metal options.

The most intriguing option might be obsidian blades - yes, the same volcanic glass our ancestors used. Modern obsidian scalpels can achieve edges just a few molecules thick, making them sharper than any steel blade.

Handle design has evolved just as much as blade technology. While traditional metal handles are still common, modern ergonomic plastic handles with textured grips reduce hand fatigue and improve control.

Milestones in Design History

The story of scalpel evolution mirrors humanity's medical progress. Those Bronze Age surgeons performing trepanation with obsidian tools were incredibly skilled, even with primitive equipment. Greek physicians refined these early tools into more sophisticated instruments. Roman medicine built on this foundation, developing techniques that would influence medical practice for over a thousand years.

The industrial age brought mass production and standardization. The 20th century introduced crucial safety innovations. Retractable blades and guarded handles began reducing accidental injuries. Today's innovations continue pushing boundaries with zirconium-nitride coatings and sonic sharpening technology.

At American Mortuary Coolers, we've seen how the right precision instruments make all the difference in professional work. Whether you're in healthcare, mortuary services, or specialized crafts, understanding your tools' history helps you choose the right one for your needs.

Types, Blade Numbers & Specific Uses

When you're standing in front of a wall of scalpel knives, the variety can feel overwhelming. But there's actually a logical system behind all those different shapes and numbers.

Surgical scalpels are your sterile, single-use precision instruments that come sealed in pouches, ready for the operating room. Craft scalpels are built for the long haul - designed to handle hours of detailed work without cramping your hand. Folding scalpels are portable designs perfect for field researchers. Safety scalpels feature retractable blades to prevent accidental cuts.

The blade numbering system is beautifully standardized. Whether you're buying from a supplier in Tennessee or California, a #10 blade is always a #10 blade:

| Blade Number | Shape | Primary Use | Handle Size |

|---|---|---|---|

| #10 | Curved cutting edge | Abdominal skin incisions | #3, #4 |

| #11 | Pointed tip | Stab incisions, precise cuts | #3, #4 |

| #15 | Small curved blade | Delicate procedures | #3, #4 |

| #20 | Large curved blade | Heavy-duty cutting | #4 |

| #22 | Pointed, angled | Autopsy procedures | #4 |

Surgical Blade Numbers & Match-Ups

Each blade number tells a story about what it's designed to do. The #10 blade features a gentle curve perfect for making initial cuts through skin during surgery. The #11 blade has a sharp, pointed tip ideal for precise stab incisions or working in tight spaces.

The #15 blade is smaller and more refined, making it ideal for plastic surgery or procedures with fragile tissues. For our friends in the funeral industry, the #22 blade is particularly important. That angled design is specifically shaped for autopsy and preparation work. At American Mortuary Coolers, we've worked with funeral homes across the country, and this blade consistently shows up on their supply lists.

Handle sizes follow the same logical pattern. #3 handles are everyday workhorses, #4 handles step up for larger blades, and #7 handles focus on precision for delicate work.

Craft & Scientific Variants

Scalpel knives have jumped way beyond the medical world. Woodcarvers use them for detail work impossible with traditional carving tools. Model makers get crisp, clean cuts that make the difference between amateur and professional results.

The beauty industry has acceptd dermaplaning using specialized scapple knife blades. In research labs, obsidian microtome blades create tissue sections measured in nanometers. When surgeons operate inside MRI machines, they use titanium blades that won't be affected by powerful magnets.

Safe Handling, Attachment & Disposal

When working with a scalpel knife or scapple knife, safety is absolutely critical. The CDC reports that around 1,000 healthcare workers suffer accidental needle sticks and cuts daily in the United States. Of all sharps injuries among medical professionals, scalpel blade accidents make up 7-8% of the total.

The "neutral zone" technique has become standard practice. Instead of passing scalpels hand to hand, instruments are placed in designated areas where the receiving person can safely pick them up. Modern safety protocols emphasize single-handed blade removal techniques and specialized blade removal devices.

Proper sterilization protocols depend on your scalpel type. Reusable handles need thorough cleaning and autoclaving between every use. Single-use instruments should never be reused. Approved sharps containers are non-negotiable for disposal.

If you're starting out with scalpel handling, check out our detailed guide on beginner scalpel blade removal mistakes - it covers common errors and how to avoid them.

Modern Safety Features

Retractable blade designs let you shield the cutting edge instantly when not actively cutting. Some newer models feature automatic retraction - the blade disappears back into the handle the moment you finish your cut.

Guarded handles provide a physical barrier between your hand and the blade. Sonic sharpening systems use ultrasonic energy to restore dulled blades. Zirconium nitride coatings help blades stay sharp longer and reduce friction during cuts.

However, research shows that safety features don't automatically equal better outcomes. One study found that safety scalpels actually caused four times more injuries than traditional reusable scalpels, mainly due to activation failures and inadequate training.

For detailed analysis of safety mechanisms, check out this scientific research on scalpel safety.

Step-by-Step Blade Attachment & Disposal

Always wear personal protective equipment - cut-resistant gloves and eye protection are essential. Never attempt blade changes with bare hands.

For attaching blades, use forceps or a dedicated blade holder. Line up the blade's mounting slot with the handle's attachment point, apply steady pressure until you hear the "click" sound. Test the connection and visually confirm proper seating.

Removing blades requires equal care. Use a dedicated blade removal device, engage the blade at its mounting point, apply steady pressure to release, then drop directly into a sharps container. Never try to catch a falling blade.

Reusable handles require proper autoclave sterilization at 121°C (250°F) for 15-20 minutes. Single-use handles go straight into medical waste disposal.

How to Choose the Right Scapple Knife

Choosing the perfect scapple knife starts with understanding exactly what you'll be doing with it. After years of helping funeral homes find the right tools, we've learned that the best choice begins with task analysis.

Consider the tissue type you'll work with and the specific motions you'll make. Material compatibility matters - steel blades become impossible near MRI equipment. The budget versus reuse calculation isn't straightforward. Disposable scalpels cost more per use but eliminate sterilization costs and reduce infection risks.

Environmental impact and regulatory compliance requirements vary by industry and location. Medical facilities face stricter requirements than craft applications.

Decision Checklist & Buying Guide

Start with blade shape considerations - what cutting motions will dominate your work? Handle ergonomics become critical for extended use. Consider whether multiple people with different hand sizes will use the same instruments.

Sterility requirements often determine whether you can consider reusable options. Safety mechanisms deserve serious consideration, but balance them against precision needs and user experience.

Supplier reputation matters more than many realize. At American Mortuary Coolers, we've built relationships with reliable suppliers because quality consistency is crucial for precision work.

For deeper technical details, our practical guide to comparing scalpel blade options walks through specifics that can make or break your decision.

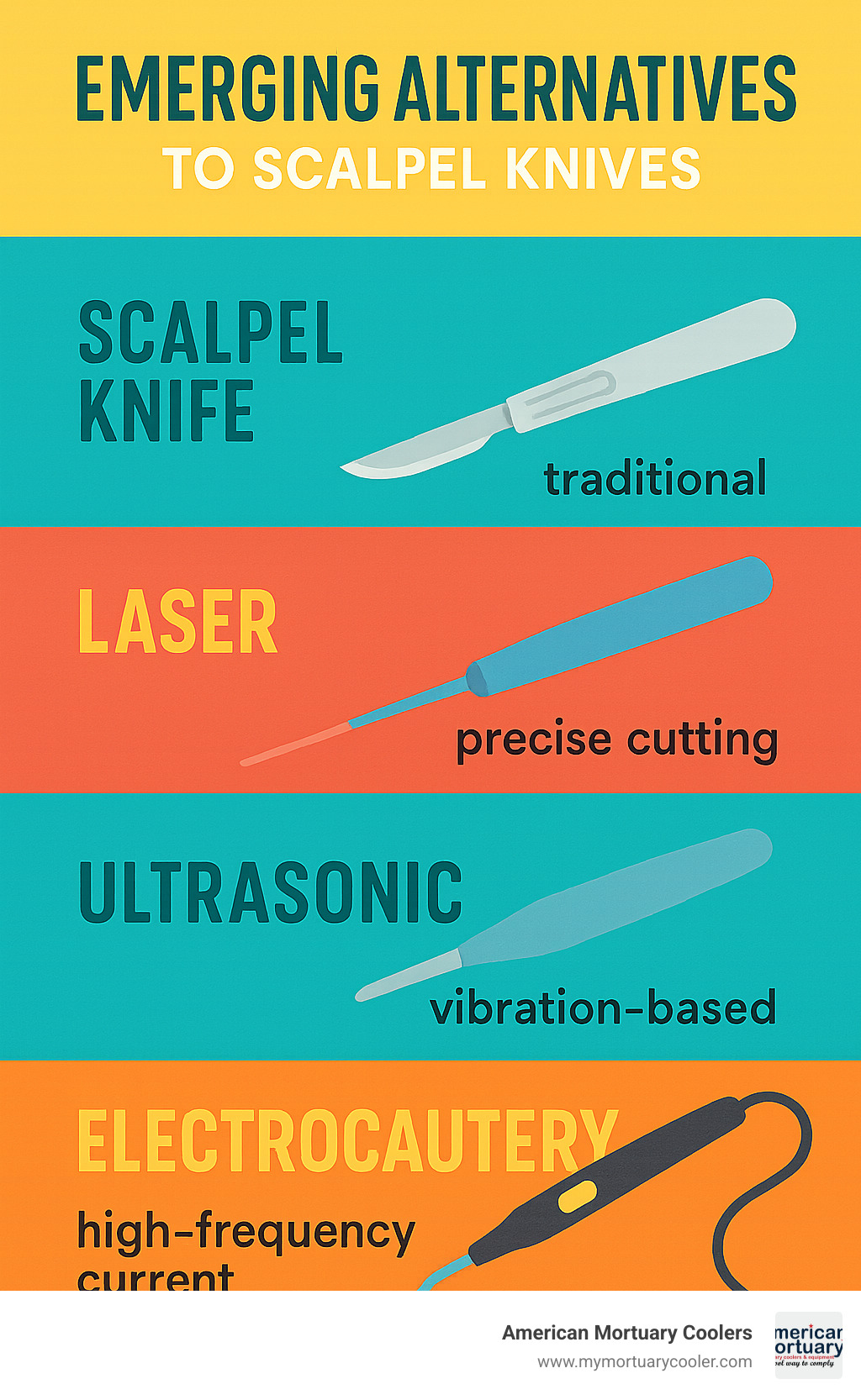

Emerging Alternatives & When to Use Them

Traditional scapple knives aren't the only option. Laser scalpels deliver precise cuts with simultaneous cauterization but are expensive and require specialized training. Electrocautery devices cut using electrical current with excellent bleeding control but cause more tissue damage.

Ultrasonic knives use high-frequency vibrations to cut and coagulate simultaneously, excelling in laparoscopic procedures. Cold plasma technology ionizes gas to create plasma fields that cut while sterilizing.

When you run cost-benefit analysis, traditional scalpels usually win for most applications. High-tech alternatives excel in specific situations but require significant equipment and training investments.

For most funeral home and mortuary work, traditional scapple knives remain the smart choice, providing necessary precision while keeping things simple and cost-effective.

Frequently Asked Questions about Scapple Knives

Why is it sometimes called a "scapple" knife instead of "scalpel"?

Both spellings are legitimate! The term "scapple knife" is a perfectly valid alternative. Both come from the Latin word "scalpellum," meaning "small knife."

While "scalpel" dominates modern medical texts, "scapple" has its own history in older medical documents and traditional woodworking circles. Regional preferences play a role - some areas stuck with "scapple" while others adopted "scalpel" as standard.

Can I reuse a disposable scalpel handle if I change the blade?

Disposable means disposable, period. These handles are engineered for single use with serious safety reasons behind that design.

Even if the handle looks pristine, the mounting mechanism can develop microscopic stress fractures causing blades to detach unexpectedly. The plastic materials aren't built to survive repeated sterilization cycles and can weaken in non-obvious ways.

At American Mortuary Coolers, we've seen what happens when people cut corners on safety equipment. The few dollars saved isn't worth the injury risk or compromised sterility.

Are ceramic or obsidian blades really sharper than steel?

Obsidian blades are absolutely incredible for pure sharpness - edges just a few molecules thick, sharper than anything manufactured from steel. Ceramic blades also achieve remarkably sharp edges and never rust.

But being sharper doesn't automatically mean better. Steel blades handle real-world stresses of daily use. Drop ceramic wrong and it might shatter. Obsidian blades are fragile under lateral pressure.

Steel blades can be resharpened, resist chipping, and won't break from accidental bumps. While obsidian has specialized surgical applications, high-quality steel remains the gold standard for most work, including mortuary applications.

Conclusion

After four thousand years of evolution, the scalpel knife remains one of our most essential precision tools. From ancient obsidian blades used in Bronze Age brain surgery to today's titanium instruments guiding MRI procedures, the core mission hasn't changed - giving skilled hands the precision they need.

What has changed is our understanding of safety and materials science. Those sobering statistics - 7-8% of all sharps injuries involving scalpels, with up to 1,000 daily incidents nationwide - remind us that choosing the right tool goes beyond cutting performance. It's about protecting the people who use these instruments.

At American Mortuary Coolers, we've worked with funeral professionals across all 48 contiguous states for decades. Whether delivering custom mortuary coolers to rural Tennessee or supplying precision instruments to large California facilities, we've learned that quality matters. Just like our mortuary coolers perform reliably when families need them most, your cutting instruments need that same dependability.

Modern scalpel knife selection offers incredible precision, improved safety features, and advanced materials. Zirconium nitride coatings extend blade life, retractable safety mechanisms prevent injuries, and ergonomic handles reduce hand fatigue.

But advances mean nothing without proper training and protocols. The most sophisticated safety scalpel can still cause injury if used incorrectly. That's why we emphasize fundamentals - proper blade selection, safe handling techniques, and appropriate disposal methods.

For those looking to deepen their understanding of precision instruments in mortuary work, our guide on cutting-edge understanding of mortuary tools offers additional insights.

The future of scalpel knives looks bright, with continuing innovations in materials and safety. Yet the principles we've discussed - matching tool to task, prioritizing safety, and maintaining professional standards - will remain constant. These aren't just guidelines; they're the foundation of professional practice.

Whether selecting your first professional scapple knife or upgrading an entire facility's instruments, the best choice serves your specific needs while keeping everyone safe. That's been true for four millennia, and it'll remain true going forward.