The Complete Guide to Comparing Stryker Autoload Prices

Why Stryker Autoload Prices Matter for Emergency Medical Services

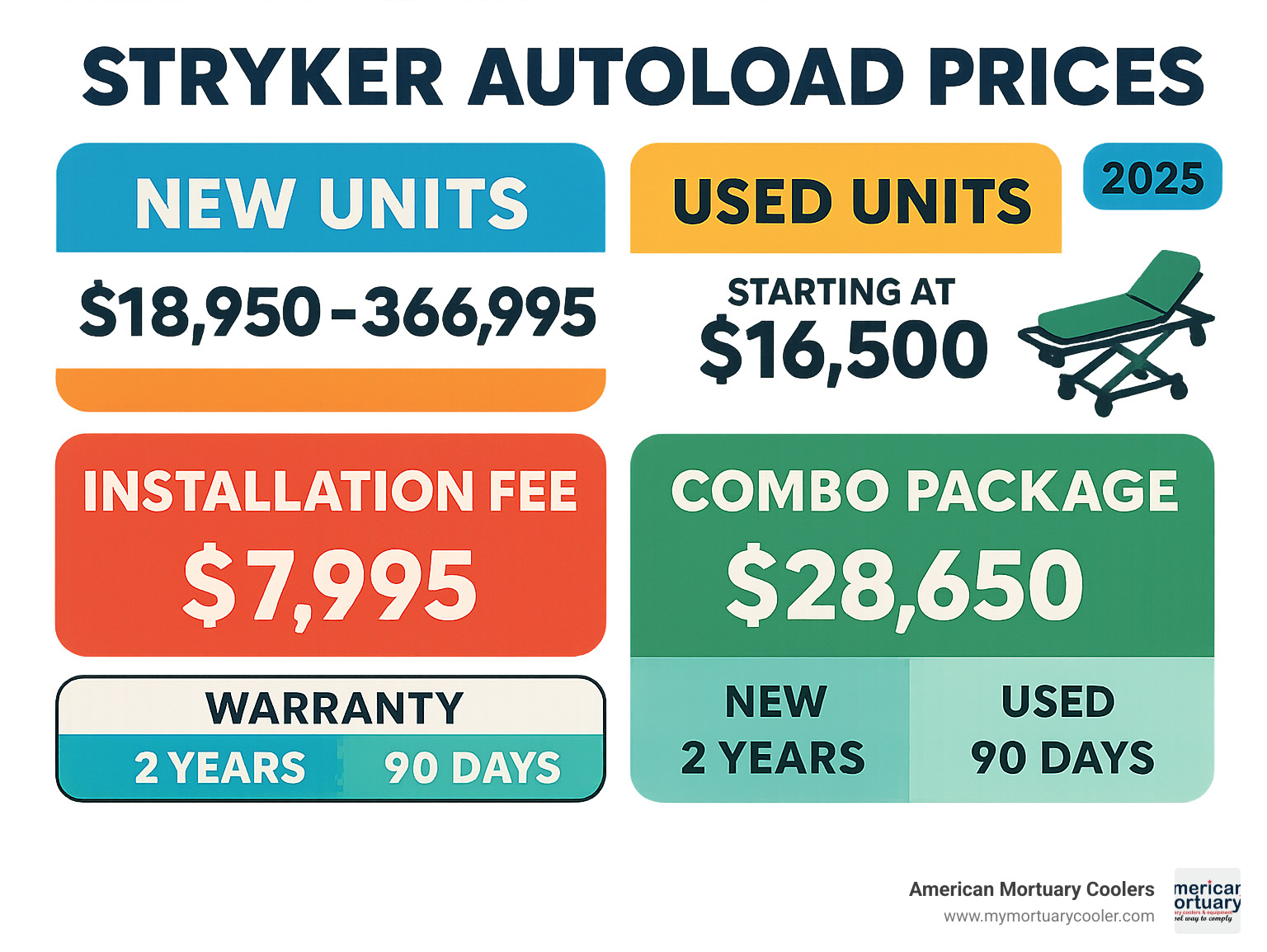

Stryker autoload prices range from $16,500 for used units to $36,995 for new systems, with installation costs adding another $7,995. Here's what you need to know:

New Stryker Power-LOAD Systems:

- $18,950 - $36,995 depending on vendor and configuration

- Model 6390 with built-in charger: $34,015 (typical 4-6 week shipping)

- Power Pro XPS combo: $28,650 (includes cot and autoload)

Used & Refurbished Options:

- Used units start at $16,500

- 90-day warranty on certified refurbished systems

- Installation fee: $7,995 (varies by vehicle and vendor)

The Stryker Power-LOAD autoload system has become the gold standard for ambulance services looking to reduce back injuries and improve patient safety. With a 700-pound lifting capacity and hydraulic support throughout the loading process, these systems eliminate the manual steering and heavy lifting that causes cumulative trauma injuries among EMS personnel.

With price variations of nearly $20,000 between vendors and significant installation costs, understanding the full pricing landscape is crucial for making an informed purchase decision.

As American Mortuary Coolers, we've worked extensively with EMS equipment suppliers and have helped numerous funeral homes and emergency services steer stryker autoload prices when upgrading their patient transport capabilities.

Stryker autoload prices terms explained:

What Is the Stryker Power-LOAD Autoload System?

The Stryker Power-LOAD system transforms what used to be a physically demanding process into a smooth, mechanical operation. Instead of EMS crews having to manually steer and lift cots, the system provides continuous hydraulic support throughout the entire loading and unloading process.

What makes this system impressive is its 700-pound lifting capacity – that's enough to handle even bariatric patients safely. The inductive charging system keeps everything powered without messy cables, while the manual backup system ensures you're never left stranded if the power goes out.

The marine-grade hydraulic components are built to last in harsh conditions, and the entire system meets dynamic crash test compliance standards. This isn't just about convenience – it's about safety for both patients and EMS personnel.

| Feature | Power-LOAD Autoload | Manual Fastener |

|---|---|---|

| Weight Capacity | 700 lbs | 650-700 lbs |

| Lifting Assistance | Full hydraulic lift | Manual only |

| Spinal Load on Operator | Minimal | High |

| Loading Time | 30-45 seconds | 60-90 seconds |

| Injury Risk | Very Low | High |

| Power Requirements | 12V DC | None |

| Maintenance | Moderate | Low |

Understanding these capabilities helps explain why stryker autoload prices reflect such a significant investment – you're paying for technology that can prevent costly worker injuries and improve patient care.

Key Safety & Ergonomic Features

The safety features built into the Power-LOAD system go far beyond basic functionality. The hydraulic lift mechanism provides smooth, controlled movement that eliminates sudden jolts or drops that can injure patients or catch operators off guard.

LED indicators at the head end give you clear visual feedback, while the control panel keeps operation simple and intuitive. The crash-test compliance means that even if the worst happens during transport, secured cots stay safely fastened.

The cumulative-trauma reduction is what really matters for EMS teams. Manual cot loading puts repeated stress on your spine with all that lifting, lowering, carrying, and bending. Over time, this leads to chronic back injuries that can end careers. The Power-LOAD system eliminates most of this physical stress.

How the System Works From Cot to Ambulance

The magic happens through linear transfer – the system guides the cot smoothly into the ambulance without you having to wrestle it into position. When a compatible Power-PRO cot approaches the ambulance, wireless communication between the systems kicks in automatically.

The safety hook secures the cot while the lifting arm provides hydraulic support throughout the process. The whole operation takes just 30-45 seconds from start to finish – nearly twice as fast as manual systems.

2024 Stryker Autoload Prices: New, Refurbished & Used

When you're shopping for a Stryker Power-LOAD system, stryker autoload prices can vary dramatically depending on where you look and what condition you're willing to accept. The official Power-LOAD – Stryker website doesn't always show the full picture of available pricing options.

Here's the reality: new systems range from $18,950 to $36,995, while used units start at $16,500. The Power Pro XPS combo package at $28,650 often provides the best value by bundling the cot and autoload system together.

New Unit Pricing Breakdown

Shopping for a new Stryker Power-LOAD system can feel overwhelming when you see price quotes that differ by nearly $20,000. The variation reflects different configurations, vendor markups, and included accessories.

Entry-level systems at $18,950 typically include basic functionality without premium features. The sweet spot for most buyers is the Model 6390 with built-in charger at $34,015. This configuration includes the inductive charging system that eliminates cable wear and connection issues. Expect 4-6 week shipping times for this popular model.

Premium systems reaching $36,995 include advanced features and often bundle installation costs. The Power Pro XPS combo at $28,650 deserves special attention. This package includes both the Power-PRO cot and the autoload system, potentially saving you $5,000 to $8,000 compared to buying components separately.

Refurbished & Used Market Snapshot

The secondary market offers compelling alternatives for budget-conscious buyers. Used Stryker Power-LOAD systems starting at $16,500 can provide nearly 50% savings compared to new units.

Certified refurbished units represent the best of both worlds. These systems undergo complete disassembly, thorough inspection, and rebuilding with new wear parts as needed. You get manufacturer-level quality with 90-day warranties that provide peace of mind.

The refurbishment process is comprehensive. Every component gets tested against original manufacturer specifications. Hydraulic systems receive new seals, electrical components get updated firmware, and the entire unit receives fresh paint and decals.

Don't overlook trade-in opportunities when calculating your total investment. Don't forget to trade-in your old stretcher! Many buyers receive $2,000 to $5,000 credit for their existing equipment.

Comparing Stryker Autoload Prices to Competing Systems

While Stryker dominates the autoload market, Ferno iN/X autoload systems range from $15,000 to $25,000, offering some savings but with different feature sets and reliability records.

Mobimedical automatic stretchers at $995 to $1,195 might seem attractive, but these units have significant limitations. Their 350-500 pound weight capacity falls well short of Stryker's 700-pound capacity.

Manual fastener systems costing $500 to $2,000 represent the budget option, but they don't address the cumulative trauma issues that drive most autoload purchases. When you factor in potential injury costs, the apparent savings often disappear.

Cost Factors That Influence Stryker Autoload Prices

When you're shopping for a Stryker autoload system, the sticker price is just the beginning. Several factors can push your total investment well beyond the initial quote.

Installation labor represents the biggest surprise cost for most buyers. You're looking at $3,000 to $7,995 depending on your ambulance model and how much modification it needs. Some newer vehicles practically welcome the Power-LOAD system, while older ambulances might need extensive surgery to accommodate the mounting hardware.

The vehicle mounting kit varies significantly based on your ambulance type. Type I, II, and III ambulances each present unique challenges. Model year affects pricing in ways many buyers don't expect. Newer Power-LOAD systems command premium prices, but they also offer improved features and longer parts availability.

Battery packs and charging systems add another layer of cost consideration. High-volume services often invest in extended battery packs at $800-$1,500 to ensure reliable performance during busy shifts.

Don't overlook shipping and lead times when budgeting. Current market conditions show 4-6 week shipping times for new units, and expedited delivery can add $500-$1,200 to your total cost.

Hidden & Recurring Costs to Budget

The ongoing expenses of owning a Stryker autoload system can catch unprepared buyers off guard.

Maintenance contracts run $1,200-$2,500 annually, but they're worth every penny. Regular maintenance prevents costly breakdowns and keeps your warranty valid.

Software updates might sound minor at $200-$500, but they're crucial for maintaining compatibility with newer cot models and ensuring optimal performance.

Replacement batteries need budgeting every 3-5 years at $800-$1,500. Modern battery technology lasts longer than earlier versions, but eventually, every battery pack needs replacement.

Staff training often gets overlooked in initial budgets. Initial operator training costs $500-$1,000 per session, and ongoing certification runs $200-$400 annually. Proper training prevents accidents and extends equipment life.

How Condition and Warranty Shift stryker autoload prices

The relationship between condition, warranty coverage, and pricing creates interesting opportunities for smart buyers. New systems command premium stryker autoload prices but include comprehensive 2-3 year warranties covering parts and labor.

Refurbished units offer the sweet spot for many buyers. These systems undergo rigorous testing and component replacement, often providing reliability comparable to new units while saving 20-30% on purchase price. The 90-day to 1-year warranties on refurbished systems provide reasonable protection.

Used systems without refurbishment carry the highest risk but offer the lowest upfront costs. Smart buyers budget for immediate repairs and shorter service life when choosing this route.

Warranty transferability significantly impacts resale value. Systems with transferable warranties maintain higher resale values and provide protection against unexpected repair costs.

Financing, Trade-In & Long-Term Value

Stryker autoload prices can feel overwhelming when you're looking at $30,000+ for a new system. But smart buyers know there are ways to make these investments work for your budget and your bottom line.

Most EMS organizations don't pay cash upfront for autoload systems. Equipment loans typically run 3-7 years at 4-8% APR, while lease programs cost $400-$800 monthly depending on the system configuration. Municipal agencies often qualify for special government rates.

Trade-in credits offer another powerful way to reduce upfront costs. Depending on your current equipment's condition, you might receive $2,000-$8,000 credit toward a new or refurbished autoload system.

The real value becomes clear in the return on investment. Organizations consistently report substantial savings from reduced workers' compensation claims, with each avoided back injury saving $15,000-$50,000. When you factor in decreased sick leave (typically $2,000-$5,000 annually) and improved employee retention, the financial case becomes compelling.

For comprehensive guidance on making the right choice for your service, check out our More info about EMT stretcher buying guide.

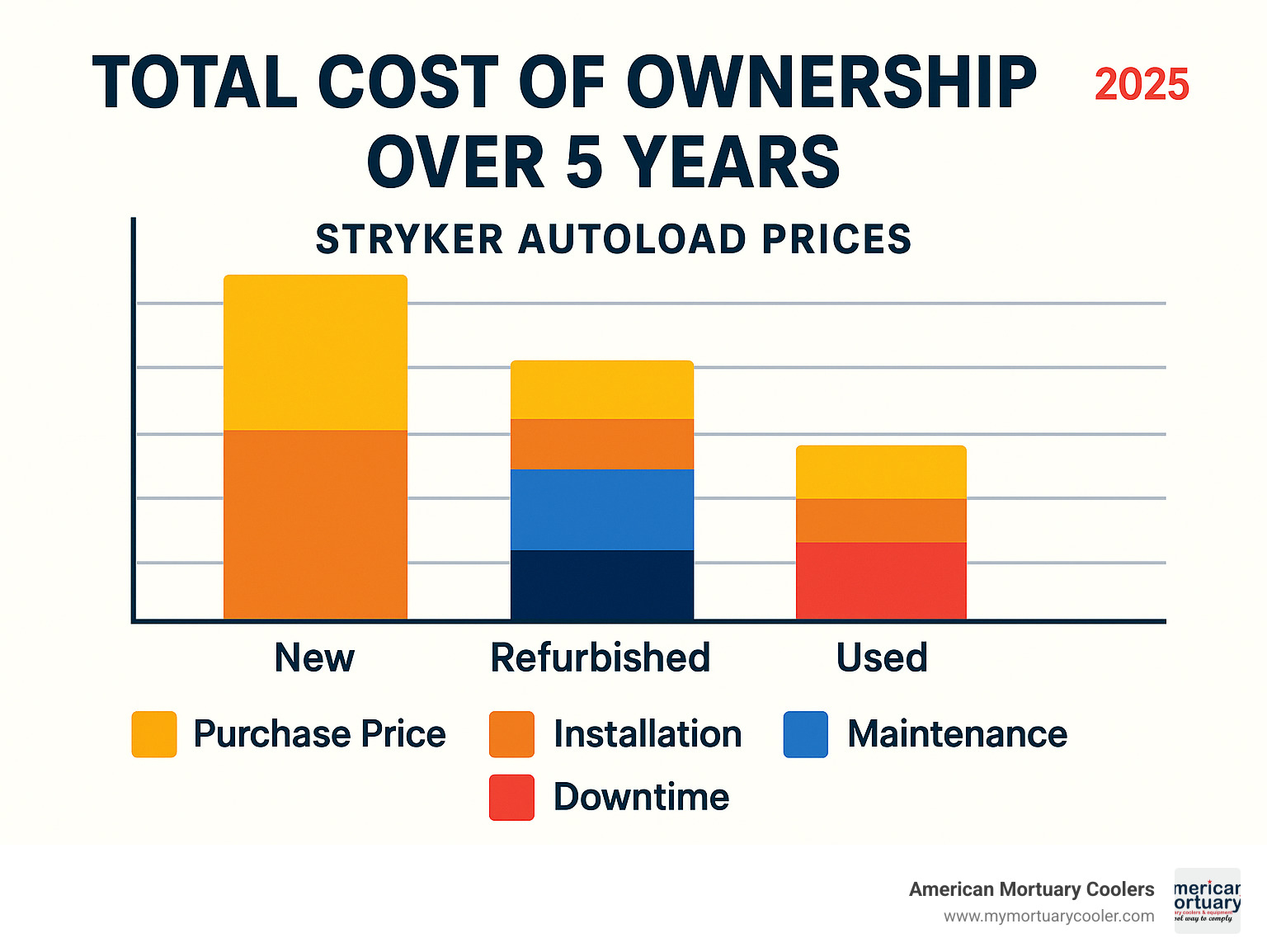

Calculating Five-Year Total Cost of Ownership

When comparing stryker autoload prices, looking at just the sticker price tells only part of the story. The real decision comes down to five-year total cost of ownership.

A new system with a $34,015 price tag will cost you approximately $52,510 over five years when you include the $7,995 installation, $8,500 in maintenance, and $2,000 for training.

Refurbished systems start with a lower purchase price around $24,000, but higher maintenance costs bring the five-year total to $44,495. The savings are real, but not as dramatic as the initial price difference suggests.

Used systems look attractive at $16,500, but higher maintenance costs – often $15,000 over five years – bring the total cost to $41,495. You save money, but you also accept more downtime and uncertainty.

The sweet spot often lies with certified refurbished systems that offer the best balance of upfront savings and long-term reliability.

Stryker Autoload Prices vs Manual Cot Fastener Costs

Manual fastener systems cost only $500-$2,000 to purchase, making them seem like the budget-friendly choice. But OSHA data tells a different story about the true cost of manual cot handling.

EMS workers experience back injuries at rates 2.5 times higher than other healthcare workers. Each injury costs an average of $32,215 when you factor in workers' compensation, replacement staffing, and lost productivity. Most services see 2-3 back injuries per 100 EMS workers annually.

The hidden costs of manual systems add up quickly. Workers' compensation claims range from $15,000-$50,000 per injury, while increased sick leave typically costs $3,000-$8,000 annually. High turnover rates mean you're constantly spending $5,000-$15,000 per replacement hire.

Organizations that invest in autoload systems typically see ROI within 18-24 months, primarily through reduced injury claims and improved operational efficiency. When you look at it this way, the question isn't whether you can afford an autoload system – it's whether you can afford not to have one.

Where to Buy and What to Inspect Before You Purchase

Finding the right vendor for stryker autoload prices requires understanding the various sales channels and their respective advantages. Each channel offers different pricing, warranty terms, and service levels.

Authorized Dealers:

- Full warranty coverage

- Professional installation

- Ongoing service support

- Higher prices but comprehensive service

Online Retailers:

- Competitive pricing

- Wide selection

- Limited service support

- Buyer assumes more responsibility

Direct from Stryker:

- Factory warranty

- Latest models

- Premium pricing

- Comprehensive support

Used Equipment Brokers:

- Lowest prices

- Variable quality

- Limited warranty

- Buyer beware approach

Pre-Purchase Inspection Checklist

Whether buying new or used, thorough inspection prevents costly surprises:

Documentation Review:

- Serial number verification

- Warranty status confirmation

- Service history records

- Installation manual availability

Physical Inspection:

- Hydraulic system operation

- Electrical connections integrity

- Mounting hardware completeness

- Corrosion or wear assessment

Functional Testing:

- Full load cycle operation

- Emergency backup system

- Control panel functionality

- Safety system verification

Software and Firmware:

- Current version confirmation

- Update availability

- Compatibility verification

- Diagnostic system check

Red Flags When Shopping the Secondary Market

Several warning signs indicate potential problems with used autoload systems:

- Missing documentation or manuals

- Non-OEM replacement parts

- Incomplete installation kits

- Excessive wear on mounting points

- Hydraulic fluid leaks

- Corroded electrical connections

- Outdated firmware versions

Buyers should walk away from deals that seem too good to be true or involve sellers who can't provide complete documentation and service history.

Recommended Marketplaces & Resources

We recommend several reputable sources for autoload systems:

New Equipment:

- FixMyAmbulance.com (competitive pricing, good service)

- Direct from Stryker (premium support)

- Regional EMS dealers (local service)

Used Equipment:

- CotDepot (wide selection, inspection services)

- Medical equipment auctions (competitive pricing)

- Trade publication classifieds (direct from users)

For broader context on stretcher markets, explore our guide on Explore High-Quality Ambulance Stretchers.

Frequently Asked Questions about Stryker Autoload Prices

We hear these questions all the time from EMS services and funeral homes looking to upgrade their patient transport equipment. After years of working with these systems, we've learned what really matters when it comes to stryker autoload prices and long-term ownership.

How long does a Stryker Power-LOAD system typically last?

A well-maintained Stryker Power-LOAD system will serve you faithfully for 10-15 years in normal EMS service. We've seen some units still going strong after nearly two decades, which speaks to the quality of those marine-grade hydraulic components and robust construction.

Your battery packs will need replacement every 3-5 years, and high-use systems typically need hydraulic service every 2-3 years. Think of it like maintaining a reliable work truck - regular care keeps it running smoothly for years beyond what you'd expect.

The secret to getting maximum life from your investment? Follow the manufacturer's maintenance schedule religiously and stick with OEM parts for repairs. We've watched systems that receive proper care exceed their expected lifespan by 20-30%.

Are refurbished units safe and compliant with current standards?

Absolutely, when they're done right. Properly refurbished Stryker autoload systems meet all current safety standards when restored by certified technicians. The refurbishment process involves complete disassembly, rigorous component testing against manufacturer specifications, and replacement of all wear items.

Here's what gives us confidence in certified refurbished units: they must pass the same dynamic crash tests as brand-new systems. They also get updated firmware to ensure compliance with current regulations.

The catch? You need to verify that refurbishment was performed by authorized service centers and includes proper documentation. Don't take shortcuts here - the paperwork matters as much as the work itself.

Can I install a Power-LOAD in any ambulance model?

Most modern ambulances can accommodate Power-LOAD systems, but installation complexity and cost vary dramatically. Type I and Type III ambulances typically require more extensive modifications than Type II units, which can affect your total investment.

The key compatibility factors include floor strength and mounting points, electrical system capacity, interior dimensions and clearances, and your existing cot fastener configuration. Each ambulance is different, even within the same model year.

Our strongest recommendation? Always get a pre-installation survey to determine compatibility and installation requirements. Some older ambulances may need structural modifications that make installation cost-prohibitive - better to know upfront than get surprised halfway through the project.

Conclusion

When you're evaluating stryker autoload prices, the sticker shock of $18,950 to $36,995 for new systems tells only part of the story. The real magic happens when you factor in the long-term savings from fewer back injuries, reduced workers' compensation claims, and happier EMS crews who aren't dreading every patient transport.

Think of it this way: one avoided back injury can save your organization $15,000 to $50,000 in claims and lost productivity. Suddenly, that autoload system starts looking like a pretty smart investment rather than just another big expense.

The total cost of ownership includes installation fees around $7,995, ongoing maintenance, and training costs. But it also includes the benefits you can't easily put a price tag on – like keeping experienced paramedics on the job instead of losing them to chronic back problems.

At American Mortuary Coolers, we've seen how the right equipment transforms operations. While we specialize in crafting custom mortuary coolers for funeral homes across Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, and Pennsylvania, we understand that reliable patient transport equipment is crucial for any organization handling human remains or providing medical care.

Smart buyers focus on matching capabilities to real needs. If you're running a high-volume urban service with frequent bariatric transports, that $36,995 top-tier system might be worth every penny. But a smaller rural service might find excellent value in a certified refurbished unit at $24,000.

The key is doing your homework. Get quotes from multiple vendors, factor in all the hidden costs we've discussed, and don't forget about trade-in credits for your old equipment. Most organizations see return on investment within 18 to 24 months – not bad for equipment that could serve you well for the next 10 to 15 years.

The bottom line? Autoload systems aren't just about moving patients more efficiently. They're about protecting your most valuable asset – your people. In an industry already facing staffing shortages and rising injury costs, investing in technology that keeps crews healthy and productive isn't just smart business. It's essential.

Ready to take the next step? Start with that comprehensive needs assessment, and remember that the cheapest option upfront isn't always the best value in the long run.

For broader insights into equipment trends and market analysis, check out our guide on More info about global stretcher markets.