The Complete Guide to Cooling Bridge Products

Why Cooling Bridge Technology Matters Across Industries

A cooling bridge is a specialized thermal management system that creates a direct pathway for heat transfer between hot components and cooling systems. Unlike traditional thermal solutions, cooling bridges use spring-loaded, compressible interfaces to maintain consistent thermal contact over time.

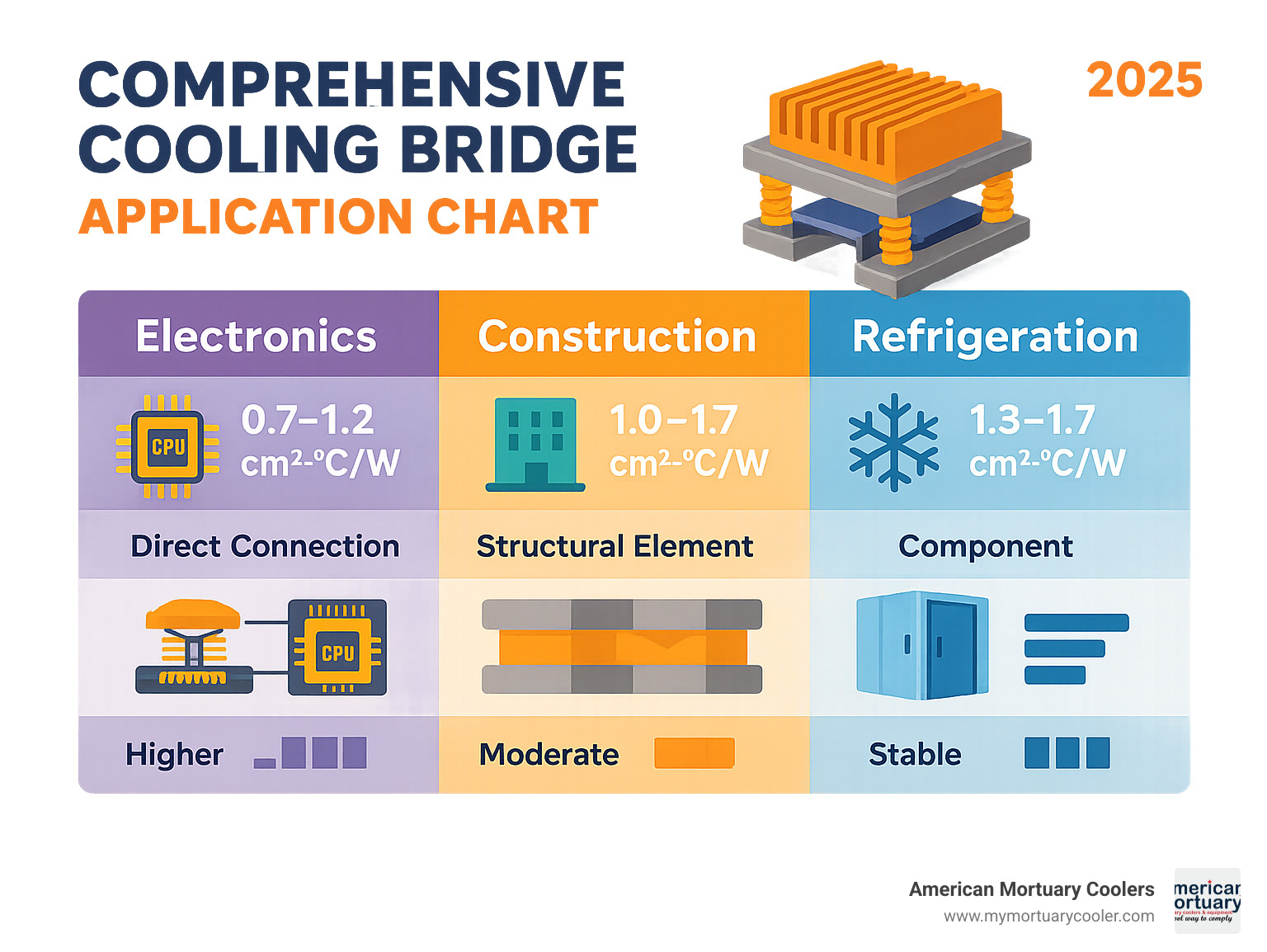

Quick Answer for "Cooling Bridge":

- Electronics: Direct thermal connection for CPUs, GPUs, and Raspberry Pi systems

- Construction: Structural element that prevents insulation breaks in buildings

- Industrial: Cooling water pipe systems for managing concrete hydration heat

- Refrigeration: Components that maintain stable temperatures in walk-in coolers

The term "cooling bridge" covers several different technologies depending on the industry. In electronics, it refers to mechanical thermal interfaces that replace traditional gap pads with up to 2× better thermal resistance. In construction, cooling bridges help control temperature in mass concrete structures like bridge foundations. For refrigeration systems, cooling bridges are critical components that maintain proper airflow and temperature stability.

Research shows that thermal bridge technology can provide thermal resistance of approximately 0.7 to 1.7 cm²°C/W, significantly outperforming traditional thermal pads. Whether you're dealing with overheating computer hardware, concrete curing temperatures, or walk-in cooler efficiency, understanding cooling bridge principles can save energy and prevent costly equipment failures.

We're American Mortuary Coolers, a national-level mortuary cooler supplier with experience in thermal management systems for sensitive applications. Our work with cooling bridge technology in mortuary equipment has shown us how proper thermal design directly impacts reliability and operational costs.

What Is a Cooling Bridge and How It Works

Think of a cooling bridge as the ultimate middleman between hot components and cooling systems. Its job is simple: create the most efficient heat transfer path possible by eliminating those pesky air gaps that love to trap heat.

The secret sauce lies in spring-loaded, interleaved parallel plates that work together like a well-choreographed dance. These plates compress to achieve what engineers call "near-zero plate gaps" while keeping the compression force surprisingly low. It's like having a firm handshake that never gets tired.

Here's where cooling bridges really shine compared to traditional solutions. Regular thermal interface materials like gap pads or thermal paste have a bad habit of degrading over time. They dry out, crack, or simply lose their effectiveness. Cooling bridges solve this headache through mechanical compression systems that maintain steady contact pressure for years.

The spring-loaded design provides 1.0 mm of typical z-axis compression while adapting to surface bumps and irregularities in all directions. Imagine trying to make two slightly wavy surfaces touch perfectly - that's exactly what these systems do automatically.

| Solution Type | Thermal Resistance | Compression Force | Longevity | Maintenance |

|---|---|---|---|---|

| Cooling Bridge | 0.7-1.7 cm²°C/W | Low, consistent | 10+ years | Minimal |

| Traditional Heatsink | 2.0-3.5 cm²°C/W | High, variable | 3-5 years | Regular |

| Gap Pads | 3.0-5.0 cm²°C/W | Medium, degrades | 2-3 years | Frequent |

What makes this technology so effective is the distributed contact system. Each bridge maintains contact at over 150 points through multiple spring-loaded plates. This means even when components expand and contract with temperature changes (which they always do), the thermal connection stays rock-solid.

Cooling Bridge in Electronics

In the electronics world, a cooling bridge pulls double duty as both a thermal interface and mechanical connector. The most popular example you'll see is the Raspberry Pi cooling bridge that clips right onto GPIO pins while keeping your mini-computer from turning into a tiny space heater during intensive tasks.

TE Connectivity has really pushed this technology forward with their thermal bridge products. Their designs replace traditional thermal materials with mechanical, compressible interfaces that deliver 20-40% lower dry interface resistance than most traditional heatsinks. That's a significant improvement that translates directly to cooler, more reliable operation.

For CPU and GPU cooling, cooling bridges work beautifully with liquid cooling systems. They create that critical thermal connection between processors and cold plates while gracefully handling the thermal expansion that happens during operation. Unlike traditional thermal pads that can compress unevenly and create hot spots over time, cooling bridges maintain consistent performance.

Modern cooling bridges for electronics pack in some impressive features: direct GPIO connectivity for development boards, compatibility with liquid cooling manifolds, spring-loaded compression for consistent contact, and low-profile designs that won't interfere with neighboring components.

Cooling Bridge in Building Construction

In construction, the term cooling bridge takes on a completely different meaning, but it's equally important. Here we're talking about managing thermal performance and controlling concrete curing temperatures - not exactly the same as keeping your computer cool, but the principles of heat management still apply.

A thermal bridge in buildings represents those troublesome areas where insulation gets interrupted, creating unwanted heat transfer paths. Research shows that thermal bridging can account for up to 30% of a home's heat loss. That's a significant chunk of your energy bill walking right out the door.

But here's where it gets interesting - cooling bridges in construction actually serve a beneficial purpose. They're carefully engineered systems designed to control temperature during concrete curing, especially in massive structures like bridge foundations.

For mass concrete applications, cooling bridges consist of embedded water pipe systems that remove hydration heat. The science behind this is pretty impressive - research shows that correlation between finite element calculations and actual measured data for cooling water pipe layout exceeds 0.976, meaning engineers can predict performance with remarkable accuracy.

Construction cooling bridges help prevent some serious problems: thermal cracking in mass concrete, excessive temperature differentials, structural damage from uncontrolled thermal expansion, and long-term durability issues that can cost thousands to repair later.

Applications and Real-World Case Studies

Cooling bridge technology shows up in some pretty amazing places, solving thermal problems that might surprise you. From the gaming rig in your home office to massive concrete bridge foundations, these systems keep things running smoothly when heat becomes the enemy.

Think about it this way - every time you've dealt with an overheating computer or walked into a perfectly climate-controlled building, there's probably a cooling bridge working behind the scenes. Data centers rely on these systems to keep thousands of servers from turning into expensive paperweights. Meanwhile, architects use cooling bridge principles to meet those strict energy codes that seem to get tougher every year.

The beauty of cooling bridge technology is how it adapts to completely different challenges. A cooling bridge managing GPU temperatures operates on the same basic principles as one controlling concrete curing in a bridge foundation, just at very different scales.

Preventing Overheating in PC Hardware

If you've ever built a high-end gaming PC with multiple graphics cards, you've probably encountered CrossFireX GPU cooling bridges. These sleek manifolds connect your graphics cards' cooling systems, making sure coolant flows evenly across all that expensive hardware.

The HD7900-XFIRE series bridges really show off what modern cooling bridge design can do. They use standard G1/4 BSPP fittings, so they'll work with whatever liquid cooling setup you're already running. Plus, they light up your GPU logos with integrated LEDs - because if you're going to spend that much on cooling, it might as well look cool too.

Here's what makes GPU cooling bridges so effective: they create balanced coolant distribution across multiple cards while reducing tubing complexity in your build. Instead of running separate loops to each graphics card, one bridge handles the whole array. The standardized G1/4 fittings mean you won't need special adapters, and that integrated LED lighting adds some serious visual appeal to your setup.

Getting the spacing right matters more than you might think. A dual-GPU system needs different bridge lengths than a four-GPU monster, and getting it wrong can create flow restrictions that leave one card running hot while the others stay cool.

Managing Hydration Heat in Bridges

Now here's where cooling bridges get really interesting - massive concrete bridge construction. When engineers pour hundreds of tons of concrete for a bridge foundation, all that concrete generates serious heat as it cures. Without proper cooling, you get thermal cracking that can compromise the entire structure.

Scientific research on hydration cooling shows exactly how to design these systems. The sweet spot turns out to be 25mm diameter pipes spaced 1.0m apart horizontally throughout the concrete mass. This configuration gives you the biggest temperature drop without making installation a nightmare.

The research reveals some fascinating details about concrete cooling. Peak temperatures hit around 35 hours after casting, which gives you a narrow window to get maximum cooling effect. The pipe diameter and inlet water temperature have huge impacts on cooling performance, while surprisingly, water flow rate changes barely make a difference.

What really impressed us is how accurate the computer modeling has become. Engineers can predict concrete temperatures with correlation coefficients exceeding 0.976 between their simulations and actual measured temperatures. That's the kind of precision that prevents costly mistakes in major construction projects.

Maintaining Stable Temperatures in Mortuary Coolers

This is where our expertise at American Mortuary Coolers really comes into play. Cooling bridge principles are absolutely critical in mortuary applications, where temperature stability isn't just about efficiency - it's about maintaining dignity and preventing serious operational problems.

Walk-in mortuary coolers need to hold that narrow 35°F-41°F temperature range while preventing the freeze-up conditions that can shut down operations. More info about walk-in cooler care explains how proper thermal management prevents the warm, humid air infiltration that causes these freeze-up headaches.

We've learned that heavy-duty vinyl curtains act as cooling bridges by creating thermal barriers at high-traffic openings. It's a simple concept, but it makes a huge difference in maintaining stable conditions.

From our years of experience, the critical factors are maintaining 50-60% relative humidity levels while ensuring proper airflow around stored items. You also need to prevent thermal bridging that could create cold spots, and regular maintenance of seals and gaskets keeps everything running smoothly.

The thing about mortuary cooler applications is that failure isn't just inconvenient - it can be devastating for funeral homes and their families. That's why we focus so heavily on getting the thermal design right from the start.

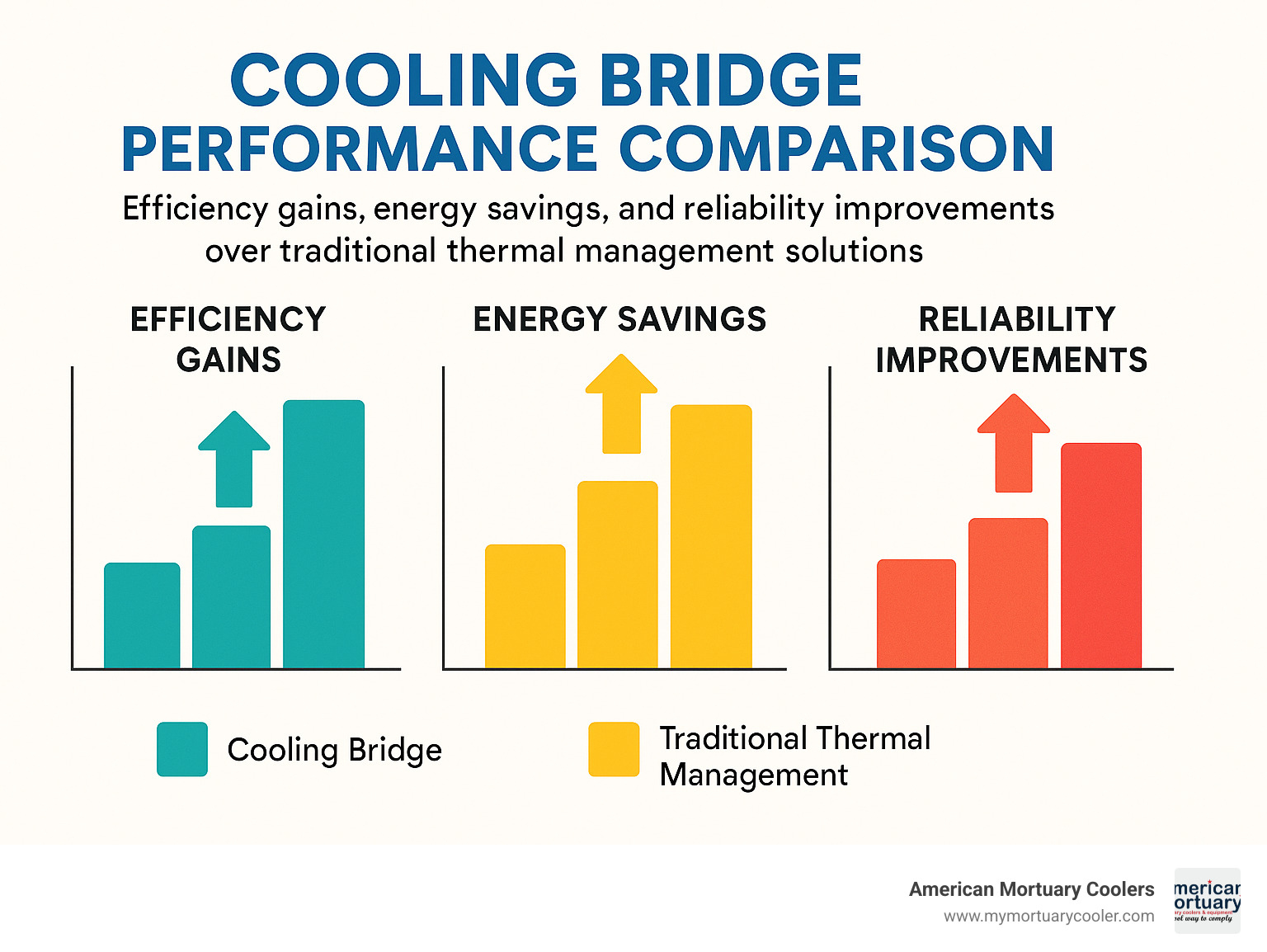

Performance Benefits, Selection & Future Innovations

When you invest in cooling bridge technology, you're not just buying better heat transfer – you're investing in a system that pays for itself through improved efficiency and reliability. The numbers tell a compelling story: thermal resistance improvements of 0.7–1.7 cm² °C/W represent up to 2× better performance compared to traditional gap pads.

These performance gains translate directly to your bottom line. When cooling systems work more efficiently, they use less energy while keeping temperatures more stable. Over a typical 10-year equipment lifespan, the energy savings alone often justify the initial investment in quality cooling bridge systems.

The future looks even brighter for this technology. IoT sensors embedded in cooling bridges now provide real-time monitoring, letting you spot problems before they become expensive failures. We're also seeing exciting developments in recyclable materials that maintain performance while reducing environmental impact.

Smart cooling bridges are becoming standard in high-end applications, featuring phase-change materials for improved thermal capacity and modular designs that make maintenance much easier. For urban applications, cooling bridges help address heat island effects while supporting sustainability goals.

How a Cooling Bridge Improves Reliability

Here's where cooling bridge technology really shines – it keeps working consistently year after year. Traditional thermal pads and gap fillers break down over time, creating hot spots that stress your equipment and shorten its lifespan. Nobody wants to deal with unexpected failures, especially in critical applications like mortuary coolers.

The spring-loaded design of modern cooling bridges automatically adjusts for thermal expansion and component settling. This means your system maintains optimal thermal contact even after thousands of heating and cooling cycles. It's like having a thermal interface that never gets tired.

Condensation prevention is another huge reliability benefit. By keeping surface temperatures consistent and above dew points, cooling bridges prevent the moisture buildup that leads to corrosion and electrical problems. In our mortuary cooler business, we've seen how proper thermal management directly impacts equipment longevity.

The reliability improvements add up to real cost savings through reduced thermal cycling stress, prevention of premature component failure, and lower maintenance requirements throughout your equipment's life. When systems run cooler and more consistently, they simply last longer.

Checklist for Choosing the Right Cooling Bridge

Selecting the right cooling bridge doesn't have to be complicated, but it does require attention to detail. Start with the basics: measure your available space carefully and verify mounting patterns before ordering anything. Nothing's more frustrating than receiving equipment that doesn't fit.

Compatibility is crucial – check that your chosen cooling bridge works with your existing cooling system. If you're planning liquid cooling integration, make sure the fittings and flow rates match your setup. For mortuary applications, more info about morgue cooler selection provides detailed guidance on regulatory compliance.

Performance specifications matter just as much as physical fit. Calculate the thermal resistance you need for your application and determine maximum compression force limits. Don't forget about operating temperature ranges – what works in a climate-controlled office might not handle the conditions in an industrial facility.

Think about long-term serviceability from the start. Can you access the cooling bridge for maintenance? Are replacement parts readily available? Required certifications like UL or NSF approval might be mandatory depending on your industry. For food service and mortuary applications, materials must meet strict sanitation requirements.

Airflow considerations often get overlooked but can make or break your cooling system's performance. Plan for adequate ventilation around your cooling bridge, and consider how the installation affects overall system airflow patterns.

Installation, Maintenance & Best Practices

Getting your cooling bridge system up and running properly isn't rocket science, but it does require attention to detail. The difference between a cooling bridge that works flawlessly for years and one that causes headaches often comes down to following proper installation procedures and staying on top of basic maintenance.

Safety always comes first when working with cooling bridges. Power down everything completely before you start - this protects both you and your expensive equipment from damage. We've seen too many costly mistakes happen when someone thought they could skip this step.

Clean surfaces are absolutely critical for optimal thermal contact. Any dirt, oil, or residue between surfaces will create thermal barriers that defeat the purpose of installing a cooling bridge in the first place. Take the time to clean thoroughly with appropriate solvents - your future self will thank you when temperatures stay exactly where they should be.

Torque specifications matter more than you might think. Too loose, and you won't get proper thermal contact. Too tight, and you risk damaging components or creating stress points that fail over time. The spring-loaded design of modern cooling bridges is engineered to work at specific compression forces, so follow the manufacturer's specs exactly.

Re-torque schedules help maintain that perfect compression as materials settle and components go through thermal cycling. It's one of those maintenance tasks that seems optional until you're dealing with overheating equipment on a busy day.

Step-by-Step Installation Guide

For electronic applications like Raspberry Pi systems, the installation process is straightforward but requires careful handling. Start by completely shutting down your pi-top or target system and disconnecting all power sources. Ground yourself properly to prevent ESD damage - those little static zaps can kill sensitive components instantly.

When mounting to GPIO pins, align the cooling bridge carefully with the pin layout before applying pressure. Press firmly but evenly to ensure all connections seat properly. Check that no pins are bent or misaligned - bent GPIO pins are frustrating to fix and sometimes impossible to repair without replacing the entire board.

Connect to the pi-top Hub following the manufacturer's routing specifications. Secure all connections and double-check your electrical connections before powering back up. A few extra minutes of verification here can save hours of troubleshooting later.

GPU water cooling bridge installations require different considerations. First, measure your exact GPU spacing - most systems use either 1.6" or 2.3" spacing, but custom configurations exist. Select the appropriate bridge length and verify that your G1/4 fittings are compatible with the manifold connections.

Position the bridge manifold between your GPU blocks and make your inlet and outlet connections. Install the provided plugs in any unused ports - even small leaks can cause major problems in liquid cooling systems. Test for leaks by pressurizing the system gradually and checking every connection point. Verify proper flow through all GPUs before considering the job complete.

Structural and construction applications involve embedding cooling water pipes during concrete pours. Plan your pipe layout using 25mm diameter pipes spaced 1.0m apart horizontally for optimal performance. Position inlet and outlet connections on opposite sides of the structure to ensure proper circulation.

During the concrete pour, install pipes in 40-50cm lifts and secure them properly to prevent displacement. The last thing you want is pipes moving out of position as concrete is placed around them. Install temperature sensors at critical locations for monitoring during the curing process.

Commission the cooling system by testing water flow through all circuits and verifying that temperature monitoring systems work correctly. Document everything for future reference - good records make maintenance and troubleshooting much easier down the road.

Long-Term Maintenance Tips

Regular maintenance keeps cooling bridge systems running smoothly and extends their operational lifespan significantly. We recommend establishing an inspection log to track performance trends and catch potential issues before they become expensive problems.

Monthly visual inspections should check for visible damage or wear, verify proper compression at contact points, and monitor temperature performance trends. Clean accessible surfaces as needed - dust and debris can surprisingly impact thermal performance over time.

Annual maintenance involves re-torquing all mounting hardware to specification, replacing worn gaskets or seals, and updating thermal interface materials if required. Test emergency shutdown procedures annually too - you want to know they work before you actually need them.

Watch for component replacement indicators like visible cracking or deformation, increased thermal resistance measurements, inconsistent temperature distribution, or reduced compression force. These warning signs usually give you time to plan replacements before complete failure occurs.

For mortuary cooler applications, align maintenance schedules with health department inspection requirements and manufacturer warranty terms. Detailed maintenance logs demonstrate compliance and can extend warranty coverage - something that's particularly valuable for the specialized equipment we work with at American Mortuary Coolers.

The key to successful long-term operation is consistency. Regular attention to basic maintenance prevents the major problems that disrupt operations and cost serious money to fix.

FAQs and Conclusion

After working with cooling bridge technology across the country - from Tennessee funeral homes to California mortuaries - we've learned that understanding thermal management isn't just about technical specs. It's about keeping your equipment running reliably when families need you most.

Whether you're dealing with overheating computer components, managing concrete temperatures in construction, or maintaining precise temperatures in walk-in coolers, cooling bridges offer proven solutions that traditional thermal management can't match. The spring-loaded design and consistent compression force make these systems particularly valuable for critical applications where failure isn't an option.

At American Mortuary Coolers, we've seen how proper thermal design impacts both equipment reliability and your bottom line. When your cooling systems work efficiently, you spend less time on emergency repairs and more time serving families during their most difficult moments.

For comprehensive guidance on selecting the right cooling systems for your facility, check out The Ultimate Guide to Walk-In Mortuary Coolers and Products. This resource covers everything from sizing requirements to maintenance schedules.

What makes a cooling bridge different from a traditional heatsink?

The biggest difference comes down to how they maintain thermal contact over time. A cooling bridge uses spring-loaded plates that automatically adjust as components heat up and cool down. Traditional heatsinks? They're basically stuck in place once you install them.

Think of it like the difference between a firm handshake that adjusts to the other person and a rigid clamp that never changes. The cooling bridge keeps that perfect contact pressure year after year, while traditional heatsinks lose effectiveness as thermal paste dries out or components shift.

The performance numbers tell the story clearly. Cooling bridges deliver 20-40% lower thermal resistance than traditional solutions. That translates to better heat transfer, lower operating temperatures, and equipment that lasts longer. We've seen mortuary coolers with properly designed thermal management run for over a decade with minimal maintenance.

Traditional heatsinks require regular maintenance - reapplying thermal paste, checking for loose connections, and dealing with performance that gradually gets worse over time. Cooling bridges maintain consistent performance for 10+ years with minimal attention.

Can I retrofit a cooling bridge onto existing equipment?

This is one of our most common questions, and the answer depends on what you're working with. The good news? Retrofitting is often possible if you plan it properly.

For electronics like Raspberry Pi systems or GPU setups, retrofitting is usually straightforward. The GPIO-based cooling bridges mount directly onto existing pin layouts, and most GPU cooling bridges work with standard waterblock mounting patterns. Just make sure you have adequate clearance and compatible connections.

Building applications get more complex but aren't impossible. You can often add thermal bridge improvements during renovations or HVAC upgrades. The key is working with qualified professionals who understand how changes will affect your overall system performance.

Refrigeration retrofits require the most planning. Walk-in cooler modifications can definitely incorporate cooling bridge principles, but you'll need to consider airflow patterns, humidity control, and compliance with health department regulations. We always recommend professional installation for refrigeration work - there's too much at stake to risk getting it wrong.

Before starting any retrofit project, have a qualified technician assess your current setup. They can identify potential compatibility issues and ensure the new system integrates properly with your existing equipment.

How do cooling bridges impact energy bills?

Here's where cooling bridges really shine - they can significantly reduce your monthly energy costs through improved efficiency and reduced system cycling. We've tracked energy usage at facilities across our service area, and the savings are consistently impressive.

The direct energy savings come from better heat transfer. When your cooling systems don't have to work as hard to maintain temperatures, they use less electricity. That 2× improvement in thermal resistance means compressors run for shorter periods and fans operate at lower speeds.

But the indirect savings often add up to even more. Better thermal management means fewer emergency service calls at 2 AM when your cooler decides to quit working. It means equipment that lasts longer before needing replacement. It means consistent temperatures that don't stress your systems with constant on-off cycling.

For walk-in cooler applications, we typically see 10-15% energy savings with proper cooling bridge design. That might not sound like much, but on a monthly utility bill of $500, that's $50-75 every month. Over a year, you're looking at $600-900 in savings.

The initial investment in quality cooling bridge technology usually pays for itself within 2-3 years through reduced energy consumption and maintenance costs. After that, it's money in your pocket every month.

Ready to improve your thermal management systems? Contact American Mortuary Coolers today to discuss how cooling bridge technology can work for your specific situation. We deliver custom solutions across all 48 contiguous states, and we specialize in systems that deliver measurable performance improvements while meeting the unique demands of the funeral industry.