The Definitive Guide to 440 Stainless Steel: Properties and Uses

Why 440 Stainless Steel Dominates High-Performance Applications

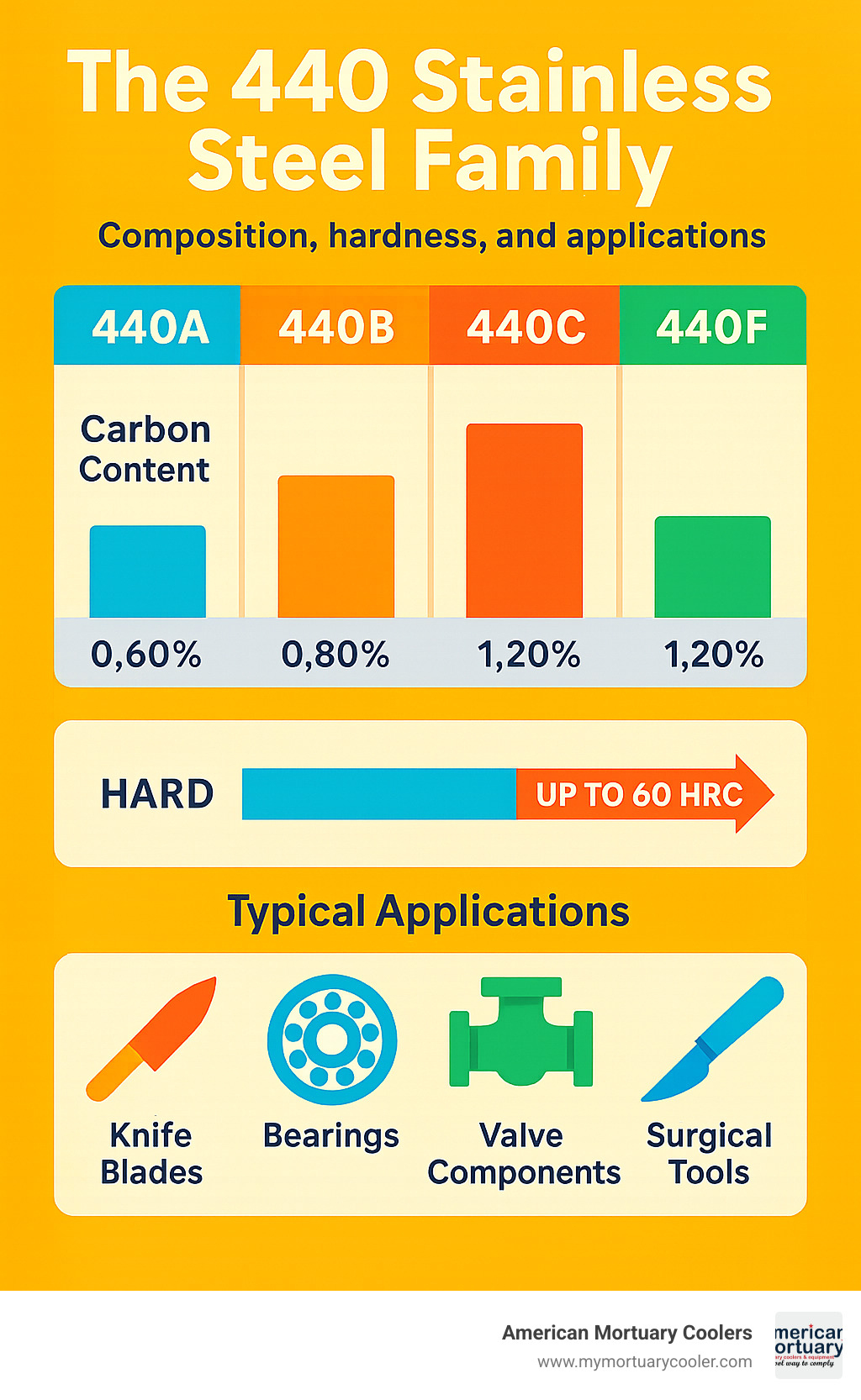

440 stainless is a high-carbon martensitic stainless steel family that achieves the highest hardness and wear resistance of all stainless steel grades. When properly heat-treated, 440C can reach up to 60 HRC while maintaining moderate corrosion resistance - making it the go-to choice for knife blades, ball bearings, surgical instruments, and precision components.

Quick Facts About .440 Stainless:

- Grade Family: 440A, 440B, 440C, and 440F variants

- Carbon Content: 0.60-1.20% (increasing from A to C)

- Maximum Hardness: Up to 60 HRC (440C)

- Key Properties: High wear resistance, moderate corrosion resistance, magnetic

- Common Applications: Knife blades, bearings, valve components, surgical tools

- Dimension Reference: ".440" often refers to 0.440-inch inner diameter on washers and fittings

The "440" designation comes from the steel's development in the 1940s as a substitute for softer stainless grades. Unlike austenitic stainless steels (304, 316), the 440 series is martensitic - meaning it can be hardened through heat treatment but becomes magnetic in the process.

When you see ".440 stainless" it can mean two things:

- Steel Grade: The 440 family of high-carbon stainless steels

- Dimension: A 0.440-inch measurement (typically inner diameter on washers, fittings, or plungers)

As specialists at American Mortuary Coolers, we've worked extensively with high-grade stainless steel specifications for mortuary equipment where durability and corrosion resistance are critical. Our experience with 440 stainless components in forensic pathology equipment has shown us why this steel family remains the gold standard for applications demanding both hardness and cleanliness.

Decoding .440 Stainless: Grade, Size, or Specification?

When someone mentions .440 stainless, they could be talking about two completely different things. It's like when your neighbor says they need a "quarter-inch bolt" - do they mean the diameter or the length?

In the stainless steel world, this double meaning happens all the time. One day you're ordering 440 stainless steel for its incredible hardness, and the next day you're looking for a washer with a .440 inch inner diameter. Same numbers, totally different purposes.

Is ".440 stainless" a steel grade?

Absolutely! 440 stainless is actually a whole family of high-carbon martensitic stainless steels. Think of it as the tough guy branch of the stainless steel family tree. You've got 440A, 440B, 440C, and 440F - each one packing more carbon and hardness than the last.

The story goes back to the 1940s when metallurgists were trying to create something special. They wanted a steel that could get razor-sharp and stay that way, but still resist rust better than regular tool steel. The result was so good at holding an edge that people started calling it "razor blade steel."

The official paperwork is pretty straightforward. Under the ASTM A276 standard, these steels are classified for bars and shapes. The UNS S44000 series covers the whole family, giving each grade its own technical passport for industrial use.

What does the .440 dimension mean on washers & fittings?

When you see .440 on a washer or fitting specification, forget about steel grades for a moment. That decimal point is telling you about size - specifically, a 0.440-inch inner diameter.

We see this all the time in our work at American Mortuary Coolers. A customer might ask for "440 stainless washers," and we have to play detective. Do they want washers made from 440-grade steel, or do they need washers with a .440" hole? Sometimes it's both!

Superior Washer makes a perfect example - they manufacture flat washers with .440" inner diameters that can be made from various stainless grades. Similarly, those press-thru ball plungers you see in machinery often have .440" mounting specifications, even when the balls themselves are made from 440C steel for wear resistance.

.440 stainless vs 440 stainless (no dot)

That little decimal point makes a big difference in what people are actually looking for. When someone searches for "440 stainless" (no dot), they're usually thinking about steel grades and material properties. But add that dot - ".440 stainless" - and suddenly you're in dimensional territory.

This matters more than you might think. We've seen purchasing mistakes where someone ordered the wrong thing because they mixed up grade specifications with dimensional requirements. Always double-check whether you need the 440 steel grade for hardness, or components with .440" dimensions for fit.

440 Stainless Steel Grades and Variants

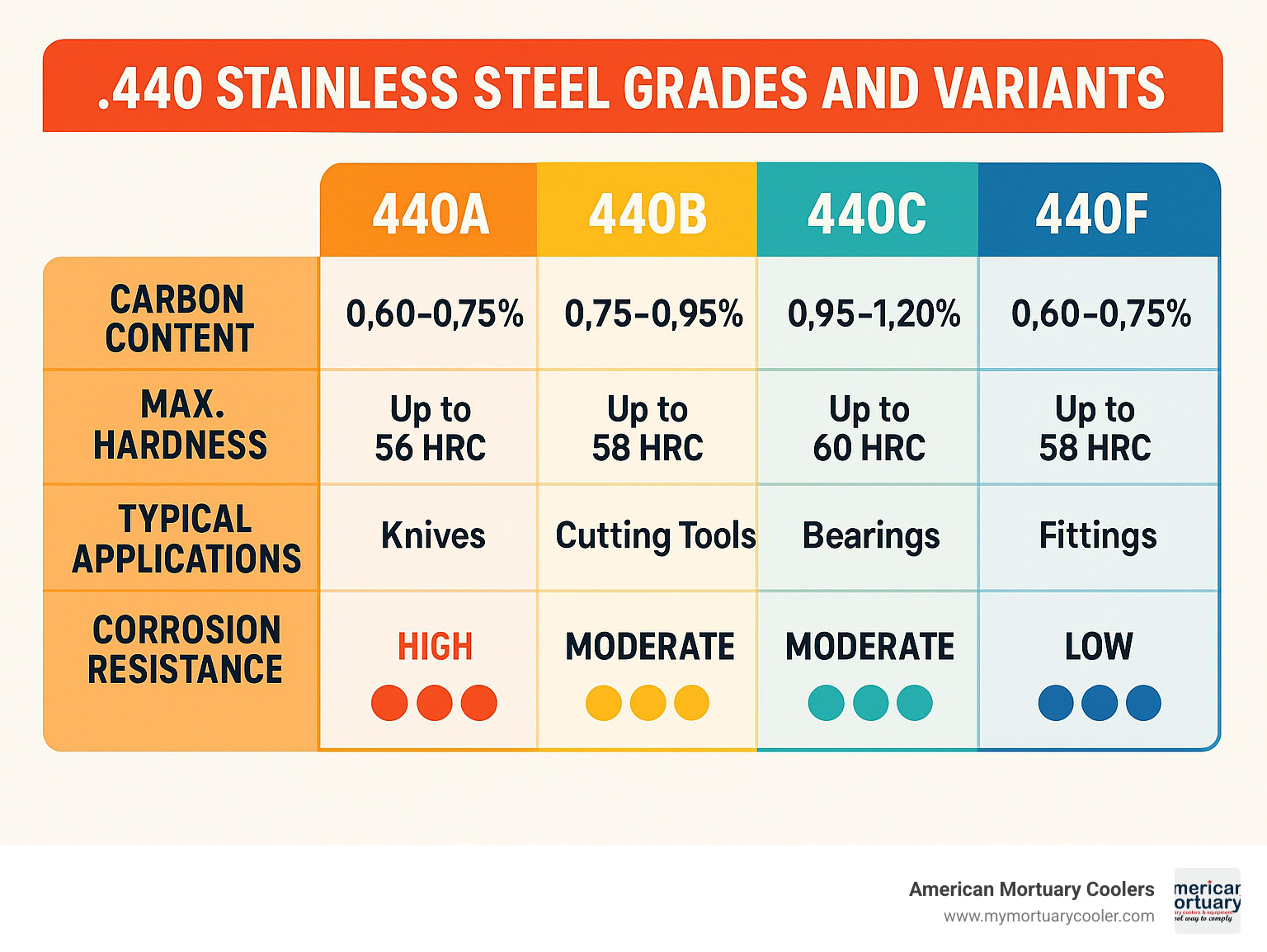

The 440 family isn't just one steel - it's actually four distinct variants that each bring something different to the table. The main difference? Carbon content. More carbon means harder steel, but it also means you'll sacrifice some corrosion resistance and workability.

Understanding these differences has saved us countless headaches when specifying materials for mortuary equipment. Choose the wrong grade, and you might end up with components that are either too soft for the job or so hard they crack under stress.

440A – the corrosion-friendly option

440A is the diplomat of the family - it gets along well with everyone, especially corrosive environments. With its 0.60-0.75% carbon content, it offers the best corrosion resistance in the 440 series while still delivering respectable hardness of 55-57 HRC.

This grade shines when you need something that stays sharp but won't rust easily. Rescue knife manufacturers love 440A because their blades need to perform reliably whether they're cutting through rope in a rainstorm or slicing seatbelts in humid conditions.

440B – balanced formula

440B sits right in the sweet spot with its 0.75-0.95% carbon content. It's like the middle child who learned to balance everyone's needs - offering decent corrosion resistance while stepping up the hardness game to 56-58 HRC.

We often specify 440B for valve components and moderate-wear applications where you need both toughness and corrosion resistance.

440C – the hardness champion

440C is the overachiever with its 0.95-1.20% carbon content, pushing hardness all the way up to RC 60 - the highest you'll find in any stainless steel grade.

After proper heat treatment, 440C delivers tensile strength up to 2030 MPa and maintains incredible wear resistance. But here's the trade-off: all that carbon makes it more brittle and harder to work with.

440C dominates the precision world - think ball bearings that need to spin smoothly for years, surgical instruments that must hold their edge through countless procedures, and high-end knife blades that serious professionals depend on.

For detailed specifications on stainless steel 440C products, you'll typically find it available in round bars, wire, and specialty forms from major suppliers.

440F & 440F-Se – machinability boost

440F and 440F-Se are the problem-solvers of the family. They recognized that 440C's hardness came with a major headache - it's incredibly difficult to machine. So they added sulfur (440F) and selenium (440F-Se) to make machining much easier.

These free-machining variants maintain similar hardness to 440C while cutting machining time significantly. 440F is perfect for screw machine parts where you need high-volume production without wearing out your tooling.

Chemical Composition & Mechanical Properties of 440 Stainless

What makes .440 stainless so special comes down to its carefully crafted recipe. The star of the show is carbon, ranging from 0.95-1.20% in 440C. Chromium sits at 16.0-18.0% - enough to provide decent corrosion resistance without going overboard. A touch of molybdenum (0.75% max) helps with hardenability, while small amounts of manganese and silicon (1.0% max each) act as deoxidizers to keep the steel clean.

The density comes in at 7.65 g/cc, making it slightly heavier than your typical stainless steel. And here's something that catches people off guard - 440 stainless is magnetic. Unlike the non-magnetic 304 and 316 grades you might be used to, 440's martensitic structure makes it stick to magnets.

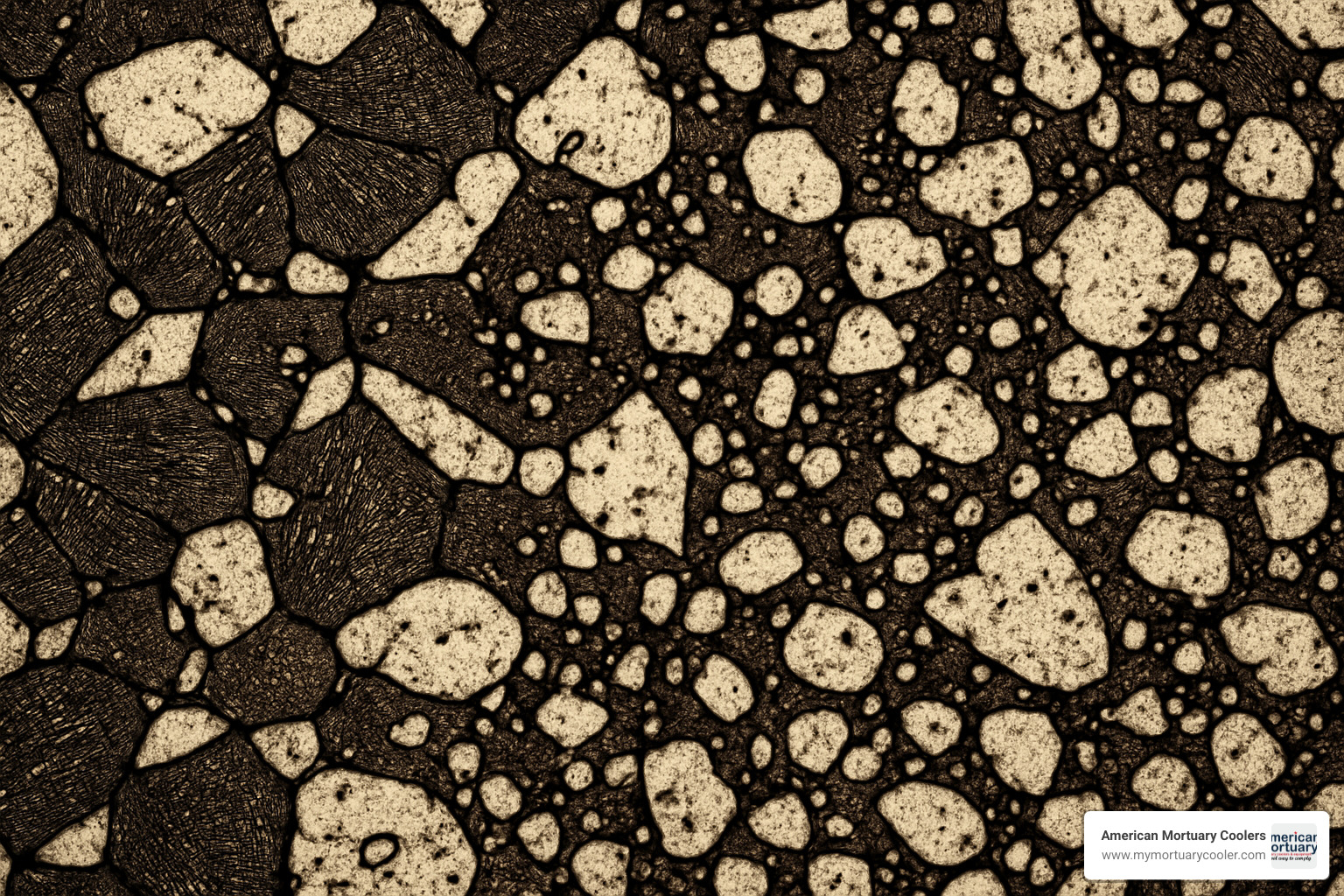

Under the microscope, you'll see that distinctive martensitic microstructure with carbide precipitates scattered throughout. It's this structure that gives 440 stainless its incredible hardness potential.

Heat-treated vs annealed property spectrum

440 stainless is like Dr. Jekyll and Mr. Hyde. In its annealed (soft) state, it's actually pretty tame. You can machine it, form it, and work with it just like regular stainless steel. The Rockwell hardness sits around B97, which is manageable for most operations.

But heat-treat that same piece of steel, and everything changes. Suddenly you're looking at Rockwell C60 hardness - hard enough to scratch glass and tough enough to outlast most other materials. The tensile strength jumps from 758 MPa up to 2030 MPa, while the yield strength starts at 448 MPa in the annealed condition.

The trade-off? Elongation drops from 14% down to just 2% after hardening. That means your super-hard steel becomes brittle - great for cutting edges, not so great if you need to bend it.

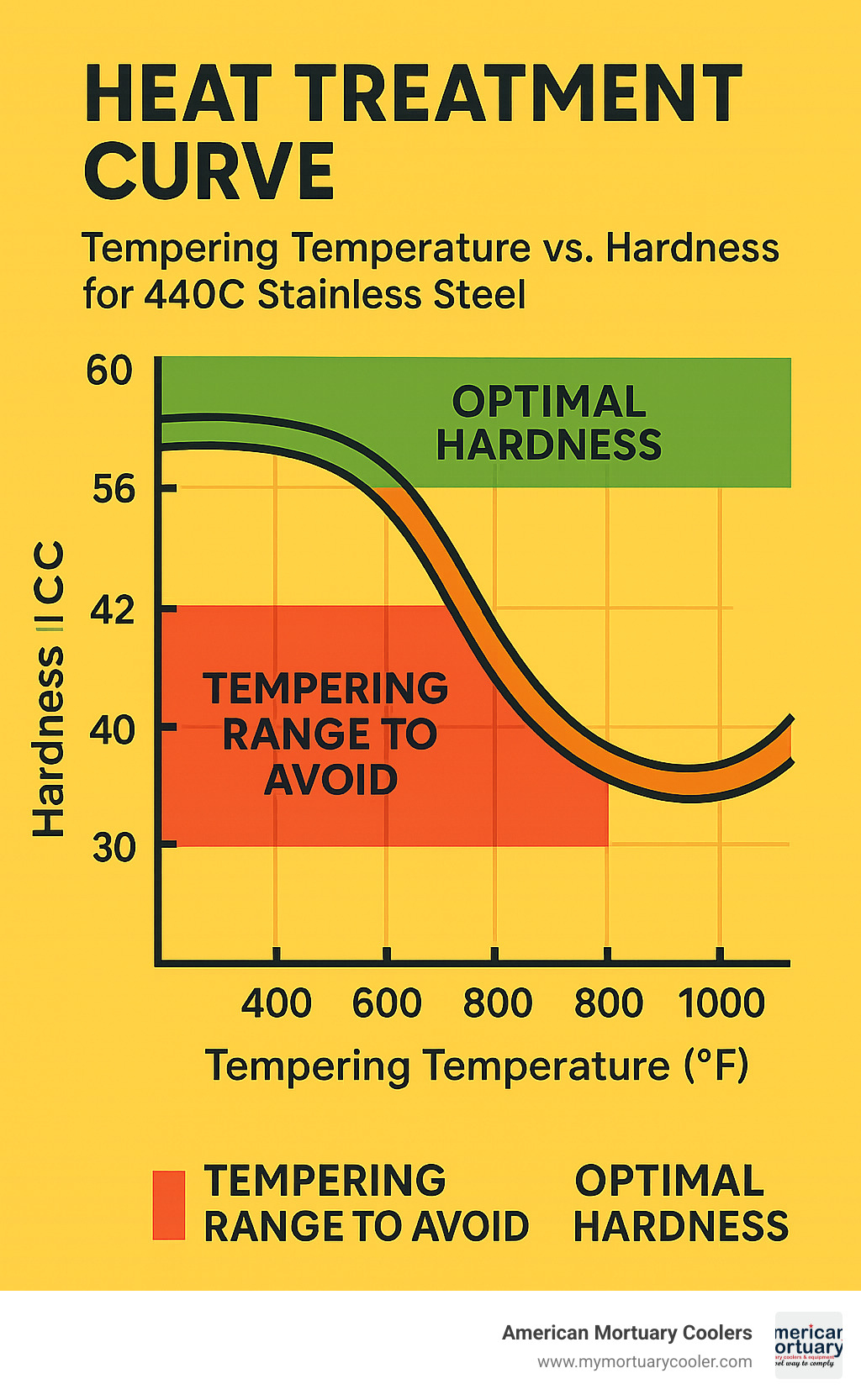

The quench-and-temper process is where the magic happens. Get the temperature and timing right, and you'll open up 440's full potential.

Corrosion performance in real-world media

Let's be honest about .440 stainless and corrosion - it's good, but it's not miracle steel. That high carbon content that gives you incredible hardness also means you're giving up some corrosion resistance compared to grades like 316.

In fresh water environments, 440 stainless performs beautifully. We've seen it handle mild acids quite well, especially when properly hardened and polished to a mirror finish. Atmospheric corrosion barely touches it, and food acids generally don't cause problems.

But saltwater is a different story. Extended exposure to marine environments will eventually get the better of 440 stainless. Strong acids and chloride-rich environments can also cause pitting and corrosion over time.

The secret weapon? Proper passivation and surface finishing. A mirror-polished 440C surface can actually approach the corrosion resistance of 304 stainless in many applications.

For those interested in the technical details, scientific research on pitting resistance shows how surface condition and heat treatment dramatically affect real-world performance.

Processing 440 Stainless: From Mill to Finished Part

Working with .440 stainless is like taming a thoroughbred - it has incredible potential, but you need to understand its temperament. The same high carbon content that gives 440 stainless its legendary hardness also makes it more demanding during processing.

The magic happens in the heat treatment process. Forging works best between 900-1100°C when the steel is nice and hot. For annealing, you'll want to heat to 850-900°C, then slow cool to 600°C before letting it air cool naturally.

The real change occurs during hardening at 1010-1065°C, followed by an oil or air quench. This is where 440 stainless develops its famous hardness. Tempering at 150-370°C fine-tunes the final properties.

Here's a critical tip: never temper in the 425-565°C range. This "danger zone" causes temper embrittlement - your steel becomes both brittle and less corrosion-resistant.

Machining tips for 440 in the annealed state

Machining .440 stainless requires patience and the right approach. Start by slowing everything down. Use about half the cutting speed you'd use for regular carbon steel. The steel work-hardens quickly if you let the tool rub instead of cut, so maintain consistent feed rates and keep those tools sharp.

Positive rake angle tools are your best friend here - they slice through the material instead of bulldozing through it. And don't skip the flood coolant. This steel generates heat like nobody's business, and that heat will ruin your day (and your tools) fast.

Once it's hardened to 60 HRC, conventional machining becomes nearly impossible. Do your machining in the annealed state, then heat treat afterward.

Welding & forming considerations

Welding .440 stainless requires respect for the material's quirks. The high carbon content means this steel wants to harden quickly, which can lead to cracking if you're not careful.

Preheat to 250°C before you start welding. This slows down the cooling rate and reduces the chance of developing hard, brittle zones. For filler metal, 309 or 310 series austenitic fillers create ductile joints that won't crack under stress.

After welding, a full anneal at 730-790°C relieves the stresses that build up during the welding process.

Surface finishing & electropolishing

The surface finish on .440 stainless does more than just look pretty - it directly affects performance. A mirror polish isn't just for show; it actually improves corrosion resistance by eliminating the tiny surface defects where rust likes to start.

Mirror polishing (#8 finish) represents the gold standard for high-performance applications. Electropolishing takes it even further, creating an ultra-smooth surface that's both beautiful and functional.

For specialized applications where both appearance and performance matter, our diamond stainless steel finishing guide covers advanced techniques that can make 440 stainless look and perform like jewelry-grade material.

Applications, Product Forms & Selection Guide for .440 Stainless

The unique combination of hardness and corrosion resistance in .440 stainless has made it the go-to choice for applications where ordinary stainless steel just won't cut it—literally and figuratively.

You'll find 440 stainless available in practically every form imaginable. Round bars from half-inch to 16-inch diameter are the most common, perfect for machining custom components. Wire forms range from hair-thin 0.040mm up to hefty 12mm diameter for springs and specialty applications. Sheet and plate stock works well for fabricated parts, while washers and fasteners take advantage of 440's wear resistance in high-stress joints.

Typical industries and parts

The medical industry has acceptd 440 stainless for good reason. When a surgeon needs a scalpel blade that stays razor-sharp through multiple procedures, 440C delivers. Surgical scissors, dental tools, and orthopedic instruments all benefit from this steel's ability to maintain cutting edges while surviving harsh sterilization cycles.

Aerospace applications demand reliability at any cost, which is why 440C appears in precision ball bearings, valve components, and measurement instruments. The steel's magnetic properties actually become an advantage in certain sensor applications.

The oil and gas industry puts 440 stainless to work in valve seats and pump components where abrasive fluids would quickly destroy softer materials.

In our work at American Mortuary Coolers, we've found that forensic and mortuary equipment represents one of 440 stainless steel's most demanding application areas. Autopsy table hardware needs to withstand constant cleaning with harsh disinfectants while maintaining precision over decades of use.

For detailed insights into autopsy table materials, we've documented how the right steel choice affects performance in these critical environments.

Advantages vs disadvantages

The advantages of 440 stainless are impressive when you need maximum performance. Exceptional hardness up to RC 60 means components that simply don't wear out under normal use. Superior wear resistance translates to longer service life and lower replacement costs. The moderate corrosion resistance beats carbon steel hands-down while the magnetic properties open up design possibilities not available with austenitic stainless grades.

But 440 stainless isn't perfect. That impressive hardness comes with increased brittleness—drop a 440C component on concrete and it might shatter where a softer steel would just dent. Machining becomes a real challenge requiring specialized techniques. Welding limitations mean you often need post-weld heat treatment to avoid cracking.

The reduced corrosion resistance compared to 316 stainless means 440 isn't suitable for saltwater or highly acidic environments. And yes, the cost is higher than common stainless grades due to the specialized processing requirements.

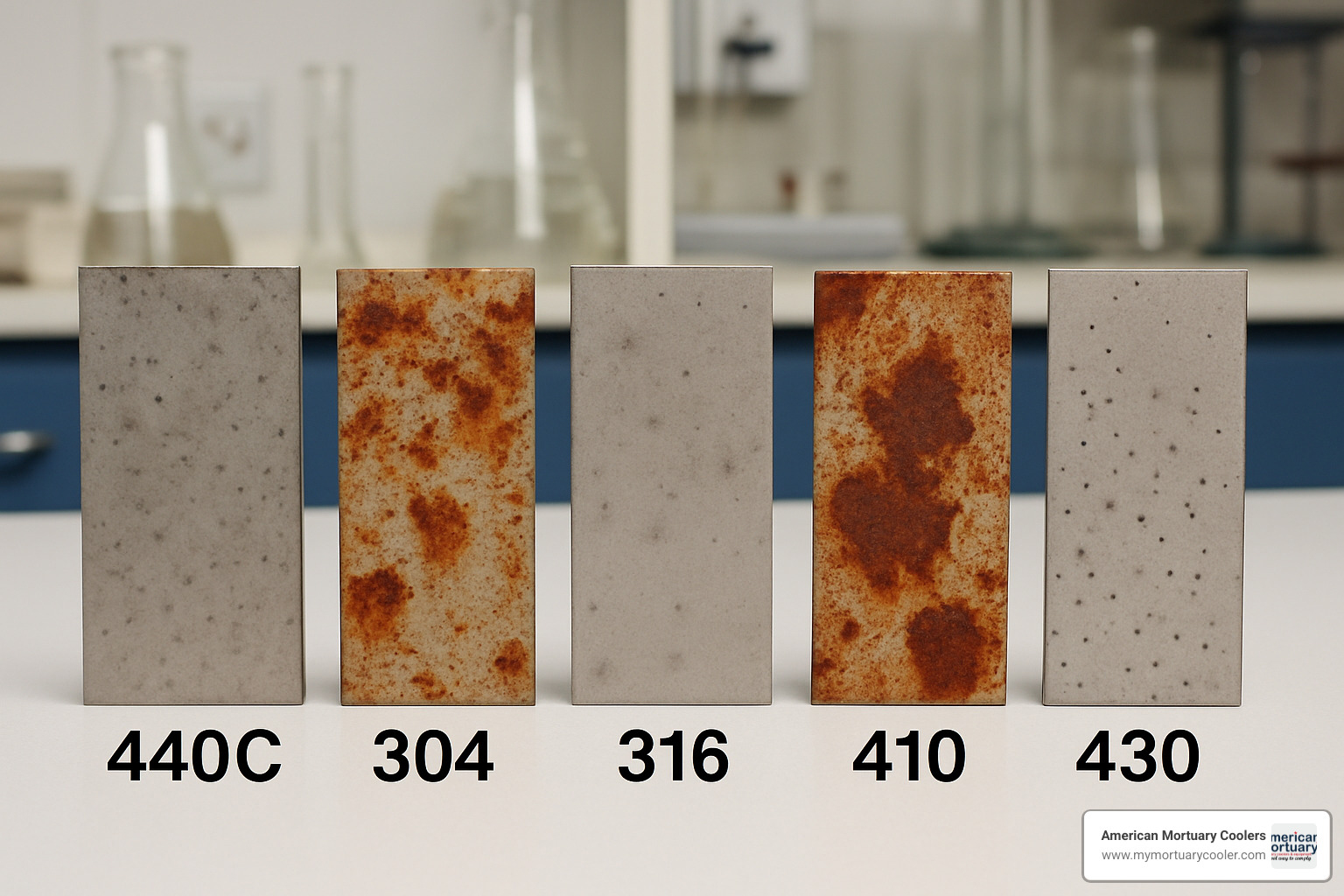

Comparing 440 to 304, 316, 410, 416, 430

Understanding how .440 stainless stacks up against other grades helps you make smart material choices. The fundamental difference is that 440 belongs to the martensitic family while popular grades like 304 and 316 are austenitic.

Against austenitic grades like 304 and 316, 440 brings hardness and magnetic properties to the table. These popular grades offer superior corrosion resistance and much better formability, but they can't be hardened like 440 can. If you need a component that stays sharp or resists wear, 440 wins. If you need something that bends without breaking or handles harsh chemicals, 304 or 316 is your answer.

Compared to other martensitic grades like 410 and 416, 440's higher carbon content delivers superior hardness and wear resistance. The trade-off is more difficult machining and welding.

Against ferritic grade 430, 440 offers the huge advantage of hardenability. Both grades are magnetic, but 430 can't be heat-treated for hardness.

The bottom line? 440 stainless occupies a unique sweet spot where you need the hardest possible stainless steel, even if it means giving up some corrosion resistance and workability.

Frequently Asked Questions about .440 Stainless

When working with .440 stainless steel, certain questions come up repeatedly. From our years of experience at American Mortuary Coolers, we've encountered these same concerns when specifying materials for mortuary equipment. Let's address the most common ones.

How hard can 440C get after heat treatment?

440C reaches an impressive 60 HRC when properly heat-treated - that's the hardest any stainless steel can get. To put this in perspective, that's approaching tool steel hardness levels while still maintaining stainless properties.

The heat treatment process is critical to achieving this hardness. You'll need to heat the steel to 1010-1065°C, then quench it in oil or air. The final step involves tempering at 150-370°C, depending on whether you want maximum hardness or need to balance it with some toughness.

This extreme hardness is why 440C dominates applications like surgical scalpels and precision bearings. It's hard enough to hold a razor-sharp edge while resisting wear that would quickly dull softer stainless grades.

Will 440 stainless rust in saltwater?

Here's the honest answer: yes, 440 stainless can rust in saltwater, especially with extended exposure. The high carbon content that gives 440 its impressive hardness also reduces its corrosion resistance compared to grades like 316 stainless.

That said, it's not defenseless. Proper surface finishing and passivation can significantly improve its saltwater resistance. We've seen mirror-polished 440C perform reasonably well in mildly corrosive environments, but for serious marine applications, 316 stainless is the better choice.

The trade-off is real - you get exceptional hardness with 440, but you sacrifice some corrosion resistance in the process. It's all about matching the material to your specific environment.

Is 440 stainless food-safe and magnetic?

440 stainless is indeed food-safe when properly finished and passivated. Its corrosion resistance handles most food processing environments just fine, though you'll more commonly see 304 or 316 grades in commercial kitchens.

And yes, 440 stainless is definitely magnetic - both in the soft annealed state and when hardened. This comes from its martensitic crystal structure, which is fundamentally different from non-magnetic austenitic grades like 304 and 316.

This magnetic property isn't a bug - it's often a feature. We've specified 440 components specifically because they respond to magnets, making them useful for magnetic separation or sensor applications in mortuary equipment. It's one of those characteristics that can actually solve design problems when you need both hardness and magnetic response.

Conclusion

Understanding .440 stainless opens up a world of high-performance applications where ordinary stainless steel just won't cut it. Whether you're working with the steel grade itself or dealing with components that have .440" dimensions, getting the details right makes all the difference.

The beauty of the 440 family lies in its versatility. 440A gives you the best corrosion resistance when you need that extra protection. 440B strikes the perfect balance for most general applications. 440C delivers maximum hardness when wear resistance is your top priority. And 440F makes machining a breeze when you're producing high volumes.

But here's the thing - 440 stainless isn't a "set it and forget it" material. It demands respect and proper processing. Heat treatment isn't optional - it's what transforms this steel from ordinary to extraordinary.

Your selection checklist should cover the basics: How hard does it need to be? What's the corrosion environment like? Can you handle the machining challenges? Do you need those magnetic properties? Can you properly heat treat it? And of course, does the performance justify the cost?

We've learned a lot about high-performance stainless steel through our work at American Mortuary Coolers. When you're building equipment for forensic pathology, there's no room for compromise. Every component needs to perform flawlessly for decades while maintaining the cleanliness standards that forensic work demands.

That's why we take material selection seriously. Whether it's precision hardware with .440" dimensions or structural components made from 440-grade steel, the right choice upfront saves headaches down the road. Our Tennessee facility gives us the flexibility to specify exactly what each application needs.

From our nationwide network, we've seen how proper stainless steel selection makes the difference between equipment that lasts decades and equipment that needs constant attention. It's not just about meeting specifications - it's about understanding how materials behave in real-world conditions.

For more information about our morgue freezer solutions and how we incorporate advanced stainless steel specifications into mortuary equipment, our technical team is ready to help. We understand that every application is unique, and we're here to help you steer the complexities of high-performance stainless steel selection with confidence.