The Ultimate Guide to Cart Lift Options

Why Cart Lifts Are Essential for Modern Operations

A cart lift is a mechanical device designed to raise and lower heavy loads, changing how businesses handle materials in workshops, warehouses, hospitals, and specialized facilities like mortuaries. These versatile machines eliminate the back-breaking work of manual lifting while boosting productivity and safety across countless industries.

What is a cart lift?

- Physical lifting device: Hydraulic, electric, or manual systems that lift materials and equipment

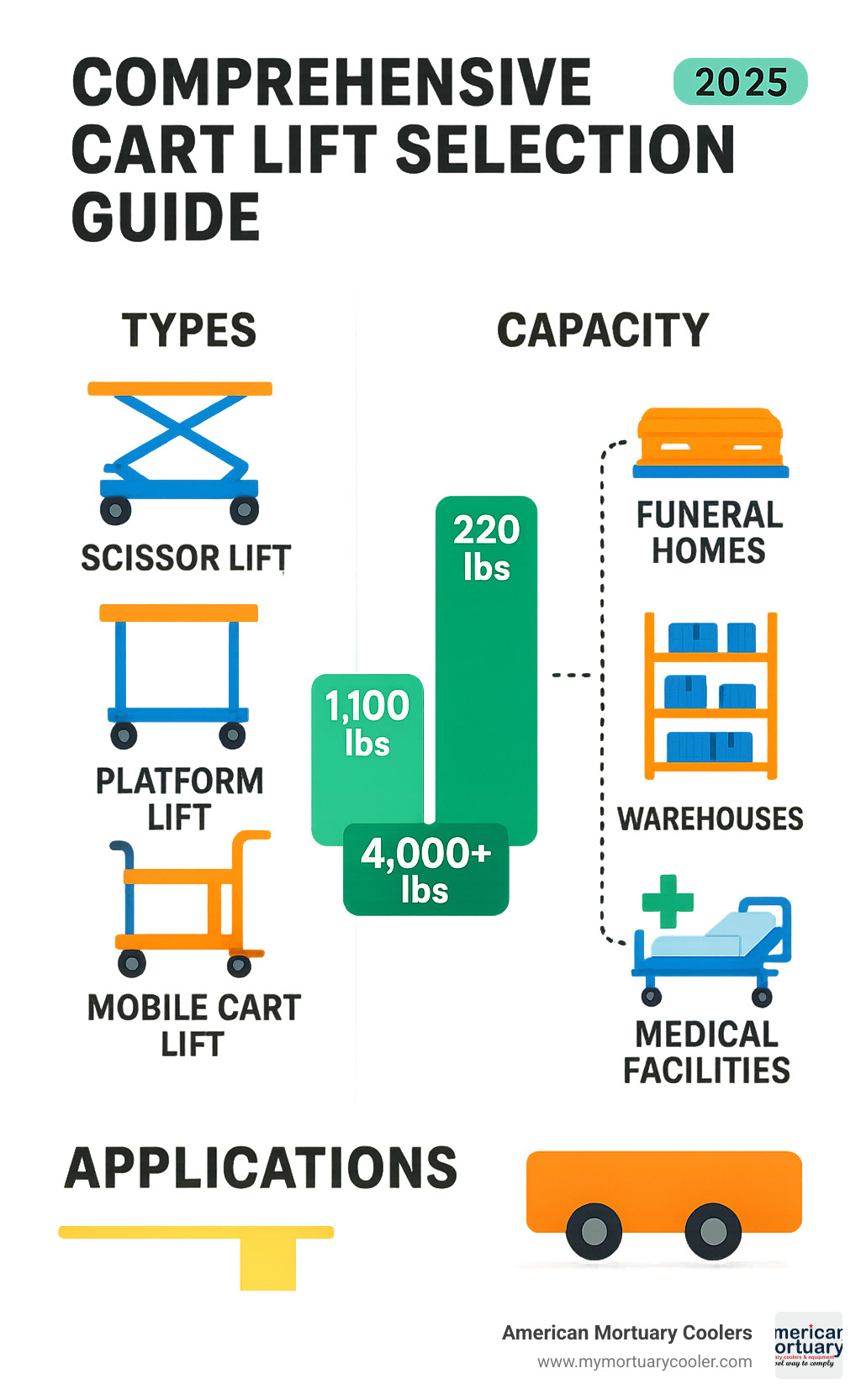

- Primary types: Scissor lifts, platform lifts, mobile carts, and stationary models

- Weight capacity: Ranges from 220 lbs to 4,000+ lbs depending on model

- Power sources: Manual foot pumps, electric motors, hydraulic systems, or battery-powered units

Note: "Cart lift" also refers to e-commerce software that recovers abandoned shopping carts, but this guide focuses on physical lifting equipment.

The research shows that hydraulic elevating carts minimize worker bending and lifting through ergonomic design, while modern electric models like the Hydralift 42A can handle up to 1,100 lbs with one-person operation. From golf cart modifications to mortuary equipment, cart lifts have become indispensable tools for reducing workplace injuries and streamlining operations.

Whether you're moving heavy caskets in a funeral home or transporting materials in a warehouse, the right cart lift can cut manual labor by 70% while meeting OSHA safety standards. Companies report immediate productivity gains after implementing these systems.

As American Mortuary Coolers, I've worked with funeral homes nationwide to integrate cart lift solutions with mortuary equipment, helping directors reduce staff strain while maintaining the dignity and efficiency their families deserve.

What is a Cart Lift? Primary Uses

Think back to the early 1900s when factory workers relied on basic pulleys and manual hoists to move heavy materials. Fast forward to today, and we have sophisticated cart lift systems that would make those early workers envious.

A cart lift is essentially your back's best friend – an ergonomic powerhouse that takes the "ouch" out of heavy lifting. Whether you're dealing with a 220-pound load or something closer to 4,000 pounds, these devices handle the strain so your team doesn't have to.

The beauty of cart lifts lies in their versatility. In workshops, they're the unsung heroes moving heavy machinery parts to just the right height for repairs. Warehouses rely on them for smooth loading and unloading operations that keep goods flowing efficiently. Hospitals use them to transport critical medical equipment between floors without breaking anyone's back.

For mortuaries, cart lifts serve a particularly important role – they allow funeral directors to handle caskets and transport needs with both safety and dignity. Automotive shops depend on them for lifting engines and heavy parts, while golf cart enthusiasts use specialized lift kits to give their rides better ground clearance.

Here's where things get a bit confusing – the term "cart lift" also pops up in the e-commerce world. Those software solutions help recover abandoned online shopping carts. But we're talking about the physical, muscle-saving kind that actually lifts real objects.

How a cart lift transforms daily operations

When you introduce a cart lift into your daily workflow, the change feels almost magical. Tasks that used to require three people and a prayer suddenly become one-person jobs. Your team can position materials at exactly the right height without the awkward bending, straining, and "lift with your legs" reminders.

The change goes beyond just moving things around. Workers stay healthier, tasks get completed faster, and everyone goes home feeling better at the end of the day. It's one of those investments that pays for itself not just in dollars, but in team morale and workplace safety.

Major Cart Lift Categories & How They Work

Understanding the different types of cart lifts helps you choose the right solution for your specific needs. Each category offers unique advantages depending on your facility's requirements, budget, and operational demands.

Manual Cart Lifts operate through foot pumps or hand cranks, requiring no electrical connection. These cost-effective solutions work well for lighter loads and occasional use.

Hydraulic Cart Lifts use fluid pressure to provide smooth, powerful lifting action. They're reliable, require minimal maintenance, and can handle substantial weights.

Electric Cart Lifts offer push-button convenience and consistent performance. The Moto-Cart Jr. ELT features a 24-volt electrical system with Curtis Controls, providing variable speed operation and automatic braking for improved safety.

Pneumatic Cart Lifts use compressed air for lifting, making them ideal for environments where electrical systems aren't practical.

Mobile Cart Lifts feature wheels or casters for easy repositioning. Research from Cartar shows their mobile hoists can free up floor space by allowing vehicles to be moved when not being worked on, improving workshop efficiency.

Stationary Cart Lifts remain in fixed positions but offer superior stability and often higher weight capacities.

Scissor Lifts use a crisscrossing support mechanism for vertical movement. They provide excellent stability and can achieve significant lift heights while maintaining a compact footprint.

Platform Lifts feature flat surfaces for versatile load handling. The Hydralift 42A platform measures 48" x 74" and can accommodate golf carts, ATVs, and scooters with its 1,100 lb capacity.

Battery-Powered Units offer cordless convenience with rechargeable power sources. Modern lithium-ion batteries provide longer runtime and faster charging compared to traditional lead-acid options.

Comparing each cart lift's pros and cons

Each cart lift type offers distinct advantages and limitations:

Manual Systems:

- Pros: Low cost, no power required, simple maintenance

- Cons: Requires physical effort, slower operation, limited capacity

- Best for: Light loads, infrequent use, budget-conscious operations

Hydraulic Systems:

- Pros: Smooth operation, high capacity, reliable performance

- Cons: Potential for fluid leaks, requires maintenance

- Best for: Heavy loads, frequent use, industrial environments

Electric Systems:

- Pros: Easy operation, precise control, consistent performance

- Cons: Higher initial cost, requires power source

- Best for: High-frequency use, precision positioning, clean environments

| Feature | Cart Lift | Lift Kit | Lift Table |

|---|---|---|---|

| Primary Use | Material handling | Vehicle modification | Workstation positioning |

| Mobility | Often mobile | Permanent installation | Usually stationary |

| Weight Capacity | 220-4,000 lbs | Vehicle-specific | 500-10,000 lbs |

| Height Range | 12-80+ inches | 3-8 inches | 6-96 inches |

| Power Source | Manual/Electric/Hydraulic | None (suspension mod) | Electric/Hydraulic |

| Cost Range | $500-$15,000 | $200-$2,000 | $1,000-$25,000 |

Key Features & Benefits That Make a Cart Lift Essential

When you're looking at modern cart lifts, you're not just buying a simple lifting device. Today's models pack sophisticated features that transform how your facility operates while keeping everyone safe and compliant.

OSHA compliance isn't just a nice-to-have anymore - it's essential for protecting your business from costly violations and liability issues. Quality cart lifts come equipped with built-in safety interlocks, emergency stops, and proper guarding that meet federal workplace safety standards.

The ergonomic design of modern cart lifts addresses one of the biggest challenges in material handling: keeping workers healthy and injury-free. Instead of forcing your team into awkward lifting positions that strain backs and joints, a well-designed cart lift allows workers to adjust load heights to maintain proper posture throughout their tasks.

The numbers tell a compelling story about injury reduction. Facilities that implement cart lift systems report up to 70% fewer lifting-related injuries compared to manual handling operations. This dramatic improvement translates directly into lower workers' compensation costs, reduced sick days, and better employee retention.

Productivity gains happen almost immediately after installing the right cart lift system. Tasks that once required multiple workers struggling with heavy loads can often be completed by one person operating the lift. The time savings compound throughout the workday, leading to substantial efficiency improvements.

Adjustable height capability gives you the flexibility to handle different tasks and accommodate various operators. Whether you're working at waist level or need to reach higher surfaces, precise positioning maximizes efficiency across diverse applications.

Safety locks provide peace of mind during operation by preventing accidental lowering while work is in progress. Quality units feature automatic locking mechanisms that engage when the platform reaches your desired height.

For hydraulic models, auto-shift pumps are a game-changer that automatically switches between high-volume and high-pressure modes. This optimization reduces the physical effort required from operators while speeding up the lifting process.

Modern cart lifts also offer impressive ROI through reduced labor costs and improved safety records. The initial investment typically pays for itself within months through decreased workers' compensation claims and increased operational efficiency.

More info about lifting tables

How a cart lift boosts facility safety & efficiency

The change that happens when you introduce a properly selected cart lift into your facility goes beyond simple material handling improvements. It creates a ripple effect of positive changes that touches every aspect of your operation.

Accident prevention becomes the immediate and most visible benefit. By eliminating the manual lifting of heavy loads, you remove the primary cause of workplace back injuries that plague so many facilities.

The task speed improvements often surprise facility managers with their impact. Operations that once required careful coordination between multiple workers can frequently be completed by a single operator in a fraction of the original time. This efficiency gain compounds throughout every workday, leading to productivity increases that can dramatically improve your operational capacity.

Selecting the Right Cart Lift for Your Needs

Finding the perfect cart lift for your facility doesn't have to feel overwhelming. After working with funeral homes across the country, I've learned that the right choice comes down to understanding your specific needs and avoiding a few common pitfalls.

Weight capacity should be your starting point, but don't just guess at the numbers. Cart lifts handle anywhere from 220 lbs for lighter tasks up to 4,000 lbs for heavy-duty industrial work. The popular Hydralift 42A sits comfortably in the middle at 1,100 lbs while still allowing one person to operate it safely. Always choose a capacity that's at least 20% higher than your heaviest expected load.

Platform sizes matter more than you might think. A compact 23" x 43" platform works great for smaller items, but if you're handling caskets or golf carts, you'll want something closer to 48" x 74". Don't forget to account for maneuvering space.

Your environment plays a huge role in equipment selection. Indoor use gives you more options, while outdoor applications need weather-resistant materials. In mortuary settings, stainless steel construction isn't just nice to have - it's essential for proper sanitation.

Power source decisions often come down to what's practical in your space. Manual systems work anywhere but require muscle power. Electric models need reliable electricity but offer smooth, consistent operation. Battery-powered units give you the best of both worlds - no cords to trip over and the power to handle demanding tasks.

Mobility versus stability is another balancing act. Mobile cart lifts with quality casters let you work anywhere in your facility, while stationary models offer rock-solid stability for dedicated workstations.

Budget planning goes beyond the sticker price. Factor in installation costs, operator training, and ongoing maintenance. Quality equipment from established manufacturers might cost more initially, but they typically save money over time through better reliability and lower repair costs.

Regulatory compliance isn't optional. ANSI, CE, and UL certifications ensure your equipment meets safety standards. OSHA compliance is mandatory for workplace use, and healthcare facilities often have additional requirements.

Warranties and support become critical when your cart lift breaks down and work stops. Look for comprehensive coverage backed by responsive technical support and readily available parts.

More info about mortuary lift equipment

When making your final decision, consider financing options that can make quality equipment more accessible. Many manufacturers offer leasing programs, with some European suppliers offering options starting around €191.30 per month.

Total cost of ownership includes factors many buyers overlook. Energy consumption, maintenance schedules, operator training, and even floor space requirements all affect your bottom line. A slightly more expensive unit that lasts longer and requires less maintenance often proves to be the better investment.

Cart lift buying mistakes to avoid

I've seen too many facilities make expensive mistakes when choosing their first cart lift. These errors are completely avoidable with a little planning and common sense.

Overloading tops the list of dangerous mistakes. When you exceed the rated capacity, you're not just risking equipment damage - you're putting people at risk. Always verify actual load weights instead of guessing.

Ignoring maintenance schedules is like skipping oil changes in your car - it works fine until it doesn't. Quality cart lifts need regular inspection and maintenance to operate safely. Budget for these costs upfront and factor in potential downtime when planning your operations.

Choosing equipment based on price alone usually backfires. That bargain unit might lack essential safety features, require constant repairs, or fail when you need it most. Consider the total cost over the equipment's expected lifespan, not just the initial purchase price.

Innovations & Trends Shaping the Future of Cart Lifts

The cart lift industry is changing faster than ever before. What started as simple mechanical devices has evolved into smart, connected equipment that's changing how we think about material handling.

IoT sensors are quietly revolutionizing how cart lifts operate. These tiny devices monitor everything from usage patterns to mechanical stress, giving facility managers insights they never had before. Instead of guessing when maintenance is needed, the equipment tells you.

Telematics systems take this connectivity even further. Imagine knowing exactly where each cart lift is located, how often it's being used, and whether it's performing optimally - all from your office computer.

The battery revolution is here, and lithium-ion batteries are leading the charge. These powerhouses last longer, charge faster, and require less maintenance than traditional lead-acid batteries. They're also lighter, which means more portable cart lifts without sacrificing power.

Auto-driving carts might sound like science fiction, but they're already working in forward-thinking facilities. These smart systems can steer predetermined routes, position loads precisely, and even communicate with other equipment.

Integrated digital scales solve a common workflow problem by combining weighing and lifting into one smooth operation. No more transferring loads to separate scales - the cart lift handles both tasks simultaneously.

Modular attachments are making single cart lifts more versatile than ever. Quick-change systems allow the same base unit to handle caskets, equipment, and supplies with different specialized attachments.

Environmental responsibility is driving eco-design principles throughout the industry. Manufacturers are creating more energy-efficient systems using recyclable materials and designing for longer lifecycles.

Latest research on mobile hoists

These innovations aren't just interesting - they're practical improvements that make real differences in daily operations. At American Mortuary Coolers, we're watching these trends closely because they directly impact how funeral homes can serve families better while protecting their staff.

Frequently Asked Questions About Cart Lifts

When you're considering a cart lift for your facility, certain questions come up again and again. Having worked with funeral homes across the country, I've heard these same concerns from directors who want to make the right choice for their staff and families.

What weight capacity do most cart lifts handle?

The weight capacity of a cart lift depends entirely on what you need it to do. Think of it like choosing a vehicle - you wouldn't use a compact car to haul a trailer, and you don't need a heavy-duty truck for grocery runs.

Most facilities find success within these ranges: Light-duty models handle 220 to 500 pounds, perfect for smaller items and everyday materials. Medium-duty units manage 500 to 1,100 pounds, which covers most general industrial needs. Heavy-duty systems can lift 1,100 to 4,000 pounds for the really substantial loads.

The popular Hydralift 42A sits right in that sweet spot at 1,100 pounds capacity. Its 48" x 74" platform works beautifully for golf carts, but we've seen funeral homes use similar models for casket handling with great success.

Here's something I always tell our customers: choose a capacity at least 20% above your heaviest expected load. This safety margin accounts for the dynamic forces that happen during lifting and ensures your equipment lasts longer.

How does a mobile cart lift differ from a fixed model?

The difference between mobile and fixed cart lifts is like comparing a rolling toolbox to a workbench - both have their place, but they serve different needs.

Mobile cart lifts give you flexibility that fixed models simply can't match. You can wheel them wherever the work needs to happen, then move them out of the way when you're done. This is huge for smaller facilities where every square foot matters.

I've seen funeral homes use mobile units to handle caskets in their preparation room, then roll the same equipment to their loading dock for transport. One piece of equipment serves multiple purposes, which makes the investment much more practical.

Setup time tells the real story though. Mobile units can be positioned quickly for different jobs, but you might need a moment to level them or engage the wheel locks. Fixed models are always ready to go, but they're married to one spot forever.

Research from Cartar shows that mobile hoists can significantly improve workshop efficiency by allowing materials and vehicles to be moved when not being worked on. The same principle applies in funeral homes - you can free up valuable preparation space when the lift isn't actively needed.

The trade-off is stability. Fixed models typically handle heavier loads more securely, while mobile units rely on quality casters and locking mechanisms.

Are there regulations I should know before buying a cart lift?

Regulatory compliance isn't optional when it comes to cart lifts - it's essential for keeping your staff safe and your business protected. The good news is that reputable manufacturers handle most of the heavy lifting on compliance, but you still need to know what applies to your situation.

ANSI standards provide the foundation for safe lifting equipment design. These requirements ensure your cart lift meets minimum safety criteria for workplace use.

OSHA regulations govern how you use lifting equipment in the workplace. They're serious about this stuff, and violations can result in significant fines. More importantly, following OSHA guidelines protects your employees from injury and your business from liability.

CE marking matters if you're dealing with European-made equipment or have international operations. It shows the equipment meets health, safety, and environmental protection standards across European markets.

Don't forget about local building codes for permanent installations. If you're mounting a fixed system or running new electrical connections, your local authorities may have specific requirements.

The funeral industry has its own considerations too. Sanitation requirements, dignified handling procedures, and space constraints all factor into equipment selection. Quality manufacturers understand these needs and can provide documentation showing their equipment meets applicable standards.

My advice? Work with established manufacturers who understand compliance requirements. They'll provide the documentation you need and can guide you through any industry-specific considerations.

Conclusion

Finding the right cart lift isn't just about moving heavy things around - it's about changing how your team works every single day. When you eliminate the back-breaking strain of manual lifting, something wonderful happens: your people can focus on what they do best instead of worrying about getting hurt.

We've seen this change countless times across different industries. A funeral director in Tennessee told us how their new cart lift system didn't just reduce injuries - it helped their staff maintain the dignity and respect families deserve during difficult times.

The numbers speak for themselves too. Facilities report up to 70% fewer lifting-related injuries after implementing cart lift systems. That's not just a statistic - that's real people going home healthy to their families every night.

At American Mortuary Coolers, we've learned something important over the years. The best equipment isn't always the most expensive or the most high-tech. It's the equipment that fits your specific needs perfectly. From our base in Tennessee, we've delivered custom solutions to funeral homes across all 48 contiguous states, and every single facility has unique requirements.

Your mortuary cooler needs to work seamlessly with your lifting equipment. When these systems complement each other, magic happens. Materials flow smoothly, staff work more efficiently, and everything just feels right.

The future looks bright for cart lift technology. IoT sensors, better batteries, and smarter controls are making these machines more capable than ever. But here's the thing - all that fancy technology means nothing if the basics aren't right. You still need equipment that's reliable, safe, and built to last.

Making the right choice comes down to three simple questions: What do you need to lift? How often will you use it? What's your budget for the total cost of ownership? Answer these honestly, and the right solution becomes clear.

Don't let analysis paralysis stop you from moving forward. Every day you wait is another day your team struggles with manual lifting. Quality equipment from established manufacturers provides the reliability and support you need to succeed.

The investment pays for itself quickly through reduced injuries, improved productivity, and happier employees. We've seen facilities recover their entire investment within months just from the efficiency gains alone.

Whether you're handling caskets with the reverence they deserve or moving materials in a busy warehouse, the right cart lift makes everything better. Your back will thank you, your productivity will soar, and your team will wonder how they ever managed without it.

More info about mortuary lifting equipment

Ready to transform your facility? Choose equipment that matches your needs, prioritize safety over savings, and partner with vendors who understand your industry. Your future self will thank you for making the smart choice today.