The Ultimate Guide to Hydraulic Lifters: How They Work and Why They Matter

Why Understanding Hydraulic Lifr Technology Matters for Your Facility

A hydraulic lifr is a mechanical lifting device that uses pressurized fluid to raise, lower, and position heavy loads safely and efficiently. These systems operate on Pascal's law - when pressure is applied to a confined fluid, it transmits equally in all directions, allowing small forces to lift much larger weights.

Quick Answer for Hydraulic Lifr:

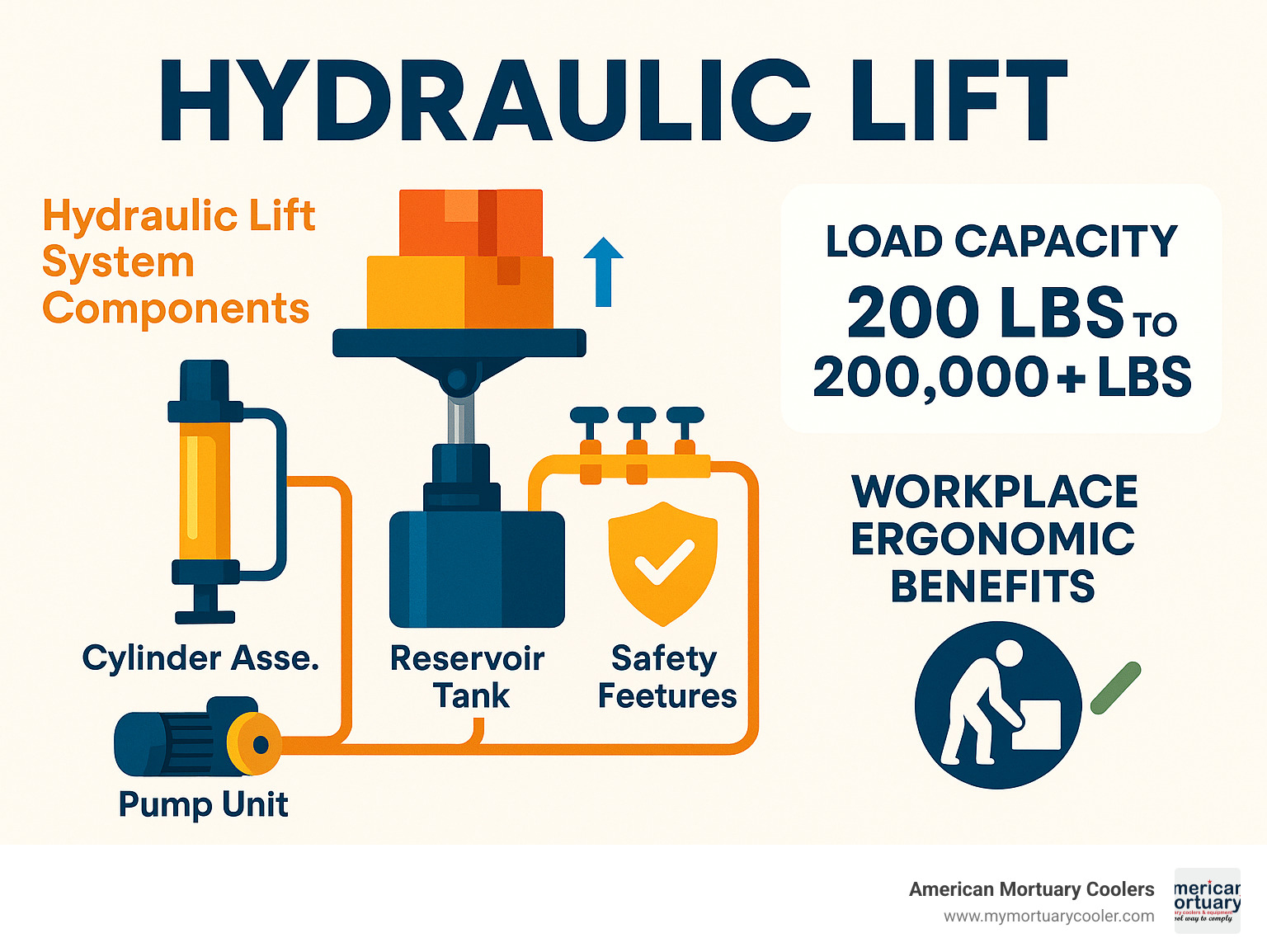

- What it is: Fluid-powered lifting system using cylinders, pumps, and valves

- How it works: Pressurized oil pushes pistons up; gravity lowers them down

- Main types: Scissor lift tables, patient lifts, boat lifts, elevators, mortuary lifts

- Key benefit: Reduces manual lifting and improves workplace safety

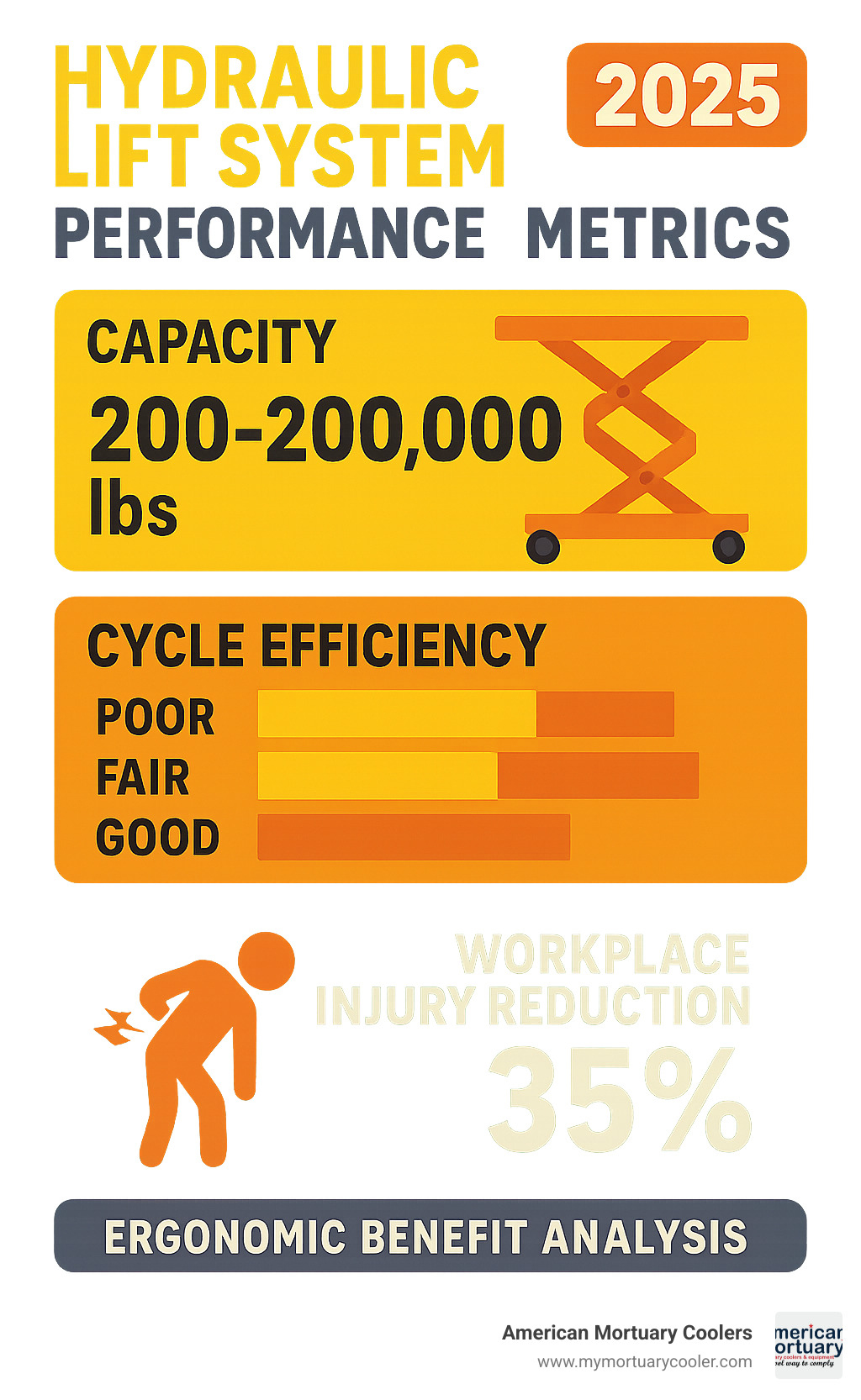

- Capacity range: From 200 lbs to over 200,000 lbs depending on model

The concept dates back centuries, but modern hydraulic lifts became practical in the 1870s with the first hydraulic elevator in New York City. Today, these systems are essential across industries - from warehouses using scissor lift tables to move materials ergonomically, to funeral homes relying on mortuary lifts for safe handling of remains.

What makes hydraulic lifts special is their ability to provide smooth, controlled movement while supporting tremendous weight. Manual hydraulic lift tables handle anywhere from 200 lbs up to 6,000 lbs, with platform sizes ranging from compact 16" x 16" units to large 63" x 31.5" surfaces.

For facility managers and equipment buyers, understanding hydraulic lift technology means making smarter purchasing decisions. Whether you need to improve worker ergonomics, meet OSHA safety standards, or handle specific loads like caskets in funeral operations, the right hydraulic system can transform your workflow.

As Mortuary Cooler, I've spent years working with funeral home directors to specify reliable hydraulic lifr systems that meet the unique demands of mortuary operations.

Related content about hydraulic lifr:

How a Hydraulic Lifr Works: Components, Physics & Operating Cycle

When you watch a hydraulic lifr smoothly raising a heavy load, you're seeing Pascal's principle in action. This fundamental law states that when you apply pressure to a confined fluid, that pressure spreads equally in all directions. This force multiplication is why a relatively small hydraulic pump can power a lift that handles thousands of pounds.

The cylinder-piston assembly forms the muscle of any hydraulic lifr system. When fluid enters under pressure, it pushes the piston up. When the fluid drains back to the reservoir, gravity brings everything back down.

Your pump and motor work as the heart of the system, creating the pressure needed for lifting. Various valves control the flow - some direct oil to the cylinder for lifting, others allow it to return for lowering, and safety valves prevent dangerous overpressure.

Modern systems come in two main flavors: holed and hole-less configurations. Holed systems require digging a pit to house the hydraulic cylinder underground. Hole-less systems use multiple pistons mounted at different points without the need for excavation.

Machine-room-less (MRL) options have revolutionized space-constrained installations by tucking everything within the shaft itself.

One of the most reassuring features is their safety descent capability. During power failures, these lifts descend slowly and controllably as oil gradually returns to the reservoir under gravity. Scientific research on fluid power confirms that hydraulic systems provide superior stability.

Key Components in Detail

The hydraulic ram - consisting of the cylinder and piston assembly - does the actual heavy lifting. The piston rod connects directly to whatever you're lifting, transferring hydraulic force to your load.

Hydraulic fluid selection matters. While basic water-based fluids work for simple applications, most professional systems use specialized oils. For funeral home applications, mineral oils provide reliable performance in climate-controlled environments.

Your hoses and seals are critical for system integrity. High-quality seals ensure the piston maintains proper pressure while moving smoothly. When these wear out, you'll notice slower operation or visible leaks.

The relief valve prevents dangerous overpressure, while flow restrictors ensure smooth movement rather than jerky operation.

Upward vs Downward Stroke Explained

The upward stroke requires active work. An electric motor drives the pump, forcing hydraulic oil into the cylinder under pressure. This pushes the piston upward, raising your load.

Downward movement is primarily a gravity return system. Opening the control valve allows oil to flow back to the reservoir. The weight pushes the piston down as oil returns to storage.

Emergency lowering systems provide crucial backup during power outages using battery backup or manual release valves.

The energy use difference is striking. Lifting requires active power, while lowering uses minimal energy since gravity does most of the work.

Main Types of Hydraulic Lifr in Today's Market

When you're shopping for a hydraulic lifr, you'll find specialized solutions for almost every lifting challenge.

Scissor lift tables are the workhorses of the hydraulic world. These use crossed, accordion-style supports that expand and contract. They typically start at 15 inches when lowered and can stretch up to 68 inches at full height.

Patient lifts have revolutionized healthcare, handling 400-500 pounds with gentle, controlled movement that keeps both patients and caregivers safe during transfers.

Boat lifts get vessels safely out of water, offering either 48-inch or 60-inch lifting heights with designs built for marine environments.

Hydraulic elevators provide smooth vertical transportation for buildings up to 6-8 floors, offering cost-effective solutions for low to mid-rise buildings.

Mortuary lifts serve funeral homes with dignity and reliability, featuring stainless steel construction for easy sanitization.

Vertical Reciprocating Conveyors (VRCs) handle industrial material transport between floors, perfect for facilities needing occasional vertical transport.

Scissor Lift Tables vs Other Hydraulic Tables

Platform sizes range from compact 16" x 16" units to industrial giants measuring 63" x 31.5" or larger. Load capacity varies from 200 pounds for delicate work up to 6,000 pounds for heavy-duty applications.

| Feature | Scissor Tables | Tilt Tables | Rotating Tables |

|---|---|---|---|

| Primary Function | Vertical lifting | Angled positioning | 360° rotation |

| Height Range | 15"-68" | Variable with tilt | Fixed height options |

| Load Capacity | 200-6,000 lbs | 1,000-4,000 lbs | 500-3,000 lbs |

| Tilt Angle | N/A | 30° or 45° | N/A |

| Best Applications | General lifting | Assembly work | Access from all sides |

Vertical vs Cantilever Hydraulic Boat Lifts

Vertical lifts lift boats straight up and down, making them adaptable to changing water levels and faster than cantilever designs.

Cantilever lifts use extending arms to position boats horizontally before lifting. When lowered completely, they preserve lake views but need more dock space.

Both systems typically offer 48-inch or 60-inch travel. Hydraulic boat-lift comparison research shows cantilever systems distribute forces more evenly, while vertical lifts provide better positioning control.

Specialized Medical & Mortuary Lifters

Medical patient lifts feature six-point cradle designs for better stability, adjusting from 21 to 72 inches in boom height. Standard models handle 400-450 pounds, while bariatric options extend to 600 pounds.

Mortuary lifts combine respectful handling with worker protection, featuring stainless steel construction and capacities from 650 to over 1,000 pounds. These may include telescoping masts and reversible forks for precise positioning.

More info about mortuary lifts shows how these systems improve both safety and efficiency in funeral operations.

Choosing the Right Hydraulic Lifr: Capacity, Safety & Ergonomics

When shopping for a hydraulic lifr, getting the sizing right saves headaches and money. Start with accurate load calculation - but you need to think about dynamic loads when moving and uneven weight distribution. Size your lift for 125% of your maximum expected load.

Platform footprint decisions affect long-term flexibility. A slightly larger platform often costs just a few hundred dollars more but provides years of versatility.

Stroke length determines working height range. Measure from your lowest loading position to the highest point where you'll position materials. Keep heavy lifting between knuckle and shoulder height to reduce worker strain.

Material choice affects performance and longevity. Steel construction provides maximum strength. Stainless steel costs more but pays for itself in medical or marine environments. Aluminum offers lighter weight while maintaining strength.

Cycle frequency matters - hydraulic VRCs work well for up to 10 cycles per hour and 100 cycles per day. Beyond that, consider mechanical lifts.

Compliance with OSHA 1926.451 and ANSI A92 isn't optional - it's the law.

Top Safety Features to Demand

Pressure relief valves protect against dangerous overpressure situations by automatically releasing excess pressure.

Mechanical locks provide backup support independent of hydraulic pressure. Never rely solely on hydraulic pressure during extended work periods.

Flow control valves regulate lifting and lowering speeds to prevent sudden movements. Emergency stop buttons must be within arm's reach from all operator positions.

OSHA guardrail essentials include top rails at 42 inches height, mid-rails positioned halfway between top rail and platform, toe boards at least 3.5 inches high, and maximum opening size of 19 inches.

Cost & Price Ranges Explained

Manual hydraulic lifts start around $500-$1,500 for smaller capacities. Powered hydraulic systems typically cost $2,000-$15,000 depending on capacity and features.

Installation costs vary significantly. Simple bolt-down units need minimal work, but holed systems require substantial excavation. Freight charges add $200-$800 depending on distance.

Rental versus purchase depends on usage frequency. Short-term projects benefit from rental at $175-$505 per day, while permanent installations justify purchase.

ROI factors include labor savings, injury reduction, and productivity improvements. Many facilities see payback within 12-24 months.

Maintaining & Troubleshooting Your Hydraulic Lifr for Longevity

Taking care of your hydraulic lifr requires consistent attention but isn't complicated. Think of it like car maintenance - regular care prevents expensive breakdowns.

Fluid checks should become routine. Fresh hydraulic oil looks clean and amber-colored. If it's dark, cloudy, or gritty, your system needs help. Check levels weekly and quality monthly.

Filter changes prevent system damage. Most need fresh filters every 6-12 months. A clogged filter makes your system struggle and overheat.

Seal inspection catches small problems before they become big ones. Look for wet spots or oil stains during regular walks around your equipment.

Heat management keeps systems running longer. Ensure pumps have good airflow and don't run continuous cycles without cooling time.

Hydraulic lift maintenance guide provides detailed maintenance procedures.

Routine Maintenance Checklist

Daily visual inspections take 30 seconds but prevent serious problems. Look for oil spots, listen for strange noises, and test safety buttons.

Weekly lubrication keeps mechanical parts moving freely. Hit pivot points and guide rails with appropriate grease, following manufacturer recommendations.

Quarterly pressure testing ensures proper safety margins. Test relief valve settings and verify lifting capacity matches specifications.

Annual overhauls provide comprehensive evaluation. Replace all hydraulic fluid, inspect seals, and perform complete safety testing.

Common Problems & Quick Fixes

Slow lifting usually means low fluid levels - check this first. Jerky motion typically indicates air in the system or contaminated fluid needing replacement.

Oil overheating can damage your entire system. Ensure adequate pump ventilation and reduce cycle frequency during hot weather.

Unusual noises often indicate cavitation from clogged filters or low fluid levels. Cylinder drift - when lifts slowly lower when they should stay put - signals serious safety concerns requiring immediate professional service.

Frequently Asked Questions about Hydraulic Lifr

What capacity range can a hydraulic lifr handle?

When people ask about hydraulic lifr capacity, they're often surprised by just how versatile these systems can be. The range is truly impressive - from delicate 200-pound units perfect for small parts handling all the way up to industrial giants that can lift over 200,000 pounds.

For most everyday workplace applications, you'll find hydraulic lifr systems handling between 500 and 6,000 pounds. This sweet spot covers everything from moving boxes in a warehouse to positioning heavy machinery parts during assembly.

Let me break this down by application type. Manual hydraulic lift tables typically start at that 200-pound minimum and go up to about 6,000 pounds - with the most popular models sitting comfortably in the 500 to 2,200-pound range. If you're looking at scissor lift tables specifically, they can reach that full 6,000-pound capacity while still maintaining a compact footprint that fits in most workspaces.

For specialized applications, the numbers shift quite a bit. Patient lifts in healthcare settings usually support 400 to 500 pounds, though bariatric models can handle up to 600 pounds for larger patients. In our mortuary equipment world, lifts typically range from 650 pounds to over 1,000 pounds - because funeral homes need that extra capacity for various situations they encounter.

Boat lifts are all over the map depending on what you're lifting out of the water, and those extreme heavy-duty applications exceeding 200,000 pounds usually require different technology altogether than your standard hydraulic systems.

How do hydraulic scissor lift tables improve workplace ergonomics?

Here's where hydraulic lifr technology really shines - it's like having a personal assistant that brings your work to exactly the right height every single time. Instead of your workers constantly bending over, stretching up high, or wrestling with heavy materials, the hydraulic system does the heavy lifting and positioning.

The magic happens when you can position loads at that perfect ergonomic zone between knuckle height and shoulder height. This isn't just about comfort - though your workers will definitely appreciate not going home with sore backs every day. It's about preventing those repetitive motion injuries that can sideline good employees and drive up your workers' compensation costs.

What I love about hydraulic systems is how smooth and controlled the movement is. There's no jarring or sudden movements like you get with manual lifting. Your workers can maintain proper posture throughout the entire process, which reduces fatigue and actually increases productivity. When people aren't fighting with their equipment, they get more done.

The versatility is remarkable too. Platform sizes range from compact 16" x 16" units for detailed work up to large 63" x 31.5" surfaces for bigger materials. The height adjustment goes from 15 inches up to 68 inches, so whether you're working with short or tall employees, everyone can dial in their perfect working position.

What's the key difference between vertical and cantilever hydraulic boat lifts?

This is one of those questions where the answer really depends on your specific dock situation and what matters most to you. Both types use hydraulic lifr technology effectively, but they go about it in completely different ways.

Vertical hydraulic boat lifts are the straightforward option - they move your boat straight up and straight down, just like an elevator. This makes them incredibly practical for areas where water levels fluctuate, because they adapt easily to changing conditions. They're also faster and more precise when you're positioning your boat, and they don't eat up as much dock space.

Cantilever lifts take a different approach entirely. They use extending arms to grab your boat horizontally first, then lift it up vertically. The big selling point here is that when you're not using the lift, it can disappear completely below the waterline. This preserves your beautiful lake view instead of having lift equipment sticking up all the time.

But cantilever systems do demand more dock real estate, and they're not as happy when water levels change significantly. They also distribute the lifting force more evenly across your boat's hull, which some boat owners prefer.

Both systems typically offer either 48-inch or 60-inch lifting heights. The 60-inch option gives you extra clearance for larger boats or areas where water levels swing more dramatically. Your choice really comes down to whether you prioritize the convenience and adaptability of vertical lifts or the aesthetic appeal of cantilever systems that can hide when not in use.

Conclusion

When you're ready to transform your facility's lifting operations, hydraulic lifr technology offers the perfect blend of reliability, safety, and versatility that modern workplaces demand. These systems have proven themselves across countless industries - from busy warehouses to sensitive healthcare environments to specialized funeral operations.

At American Mortuary Coolers, we've witnessed how the right hydraulic lifr system can completely change a funeral home's daily operations. Our clients across Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, Pennsylvania, and throughout all major regions consistently tell us these systems don't just lift loads - they lift the burden of dangerous manual handling from their staff.

The custom solutions we provide reflect years of listening to funeral professionals describe their real-world challenges. A mortuary lift isn't just about moving weight - it's about maintaining dignity, protecting workers, and ensuring smooth operations during emotionally difficult times.

Our direct delivery across the contiguous 48 states means you're never waiting weeks for critical equipment. We understand that funeral operations can't pause for equipment delays.

The return on investment speaks for itself. Reduced workers' compensation claims, improved staff retention, better workflow efficiency, and improved safety compliance all contribute to your bottom line. More importantly, your team goes home each day without the aches and strains from manual heavy lifting.

As OSHA regulations continue emphasizing workplace ergonomics and safety standards become more stringent, hydraulic lifting systems aren't just smart investments - they're becoming essential equipment.

For funeral professionals ready to explore how hydraulic lifting can improve their operations, we're here to help you find the perfect solution.